My Garage

My Account

Cart

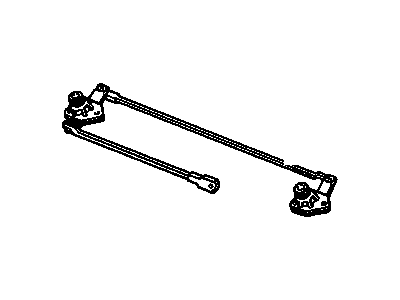

Genuine Cadillac Fleetwood Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Transmission Assemblies found

Cadillac Fleetwood Transmission Assembly

Each OEM Cadillac Fleetwood Transmission Assembly we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Fleetwood Transmission Assembly Parts Questions & Experts Answers

- Q: How to remove and install the automatic Transmission Assembly on Cadillac Fleetwood?A:To get rid of as well as place in the 4T60 and 4T60-E transaxle, beginning with disconnection of negative battery cable as well as removing air cleaner assembly followed by exhaust crossover pipe. Disconnect shift linkage, shift cable, bracket along with label those electrical connectors for the converter clutch, cruise control servo and also Neutral Safety Switch. Take off topmost transaxl-to-engine bolts and stud disconnect vacuum line at vacuum modulator and support engine using engine support tool. Raise vehicle securely, remove front wheel and tire assemblies, disconnect both ball joints from steering knuckles and remove half shafts from transaxle. Remove stabilizer bolt with clamp, left engine and A/C splash shields and wire harness cover. Also take out the left front engine & transaxle mount to cradle attachments which include No1 cradle insulator bolt on left side along with its cradle assembly. Disconnect oil cooler lines together with bracket then remove transaxle-to-engine support bracket. Remove right rear mount to transaxle bracket plus left rear transaxle mount to transaxle attachment(s). Eliminate flexplate splash shields along with torque converter-to-flexplate bolts. Place a suitable jack under the transaxle then remove one of the transaxle to engine bolts through right wheel well lastly pull it out of the vehicle. To install position the lower-transmission-to-engine bolts/studs in place followed by attaching torque-converter to flywheel holes via flexplate-splash guards. After that put back oil cooler tubes & supports after installing both rear transmission mounts (right&left)and attach the transmission gap filler plain plate. The following involves inserting into position, screwed back or fixed in place are; Left No1cradle insulator bolt plus cradle assembly while fitting in vacuum pump system comes next stepwise pattern in A/C splash shield replacements for engines on each side amongst others related ones. The half shafts should be installed and then the lower ball joints in addition to the outer tie rod ends which are screwed at place. Put back into position, tightened or installed in place include; (1) Front wheel wells which have splash shields removed from them. (2)Both sensors of front suspension position while the stabilizer link is taken out of strut on both sides. Remove cotter pins together with nuts for tie-rod ends as well as lower ball-joint along with cotter pin afterwards. Finally remove halfshafts, power steering filter and A/C splash shield from frame. Remove ABS modulator and engine oil pan-to-transaxle bracket then torque converter cover & torque converter-to-flexplate bolts. Place a compatible jack below the transaxle and take out the transaxle-to-engine bolts. Finally, detach the transaxle from the vehicle. First off, get the transaxle positioned in the vehicle and set up its lower bolts to join it with the engine. Re-install torque converter-to-flexplate bolts and torque converter cover, connect oil cooler limes. Connect right and left rear transaxle mount attachments and transaxle-to-engine support bracket. Also, reattach power steering hose to auxiliary cooler, making sure that electrical harness and connector are connected to front of cradle. Give suitable jack to support rear part of cradle when removing 4 rear cradle bolts Lower jack slightly so as to gain access to power steering gear heat shield where return line fitting is located, remove heat shield and disconnect return line. Put in a plug at line and gear opening Unfasten power steering electrical connector then raise jack higher such that one rear cradle bolt on each side may be finger-tightened during reinstallation Remove jack by supporting frame with another suitable jack while removing 6 frame mount bolts Lower frame or raise vehicle together with installed steering gear Label then unplug electrical connectors from transaxle housing, vehicle speed sensor and ground; remove transaxle harness from transaxle clip Undo fuel line bundle from transaxle; also undo left/right mount/bearing assemblies Support transmission assembly using proper floor transmission jack before taking out engine-to-transmission heat shield/bracket as well as remaining transmission-to-engine fasteners Lower transmission until manual shift linkage along with neutral safety switch/objective is cleared; after that take out vehicle speed sensor/ object for measuring oil pressure so that oil can start dripping To adjust throttle linkage make sure cable slider is fully retracted position while pressing adjusting tab at TV cable-end of engine Move slider towards fitting but once more freed tab after which throttle lever should be turned completely around The slider should move towards the lever when it is at full throttle Opening the transaxle adapt parameters and changing the oil life indicator for the transmission requires specific procedures.