×

My Garage

My Account

My Cart

Genuine Pontiac Vibe Clutch Disc

Friction DiscEnter your vehicle info to find more parts and verify fitment

- Select Vehicle by VIN

- Select Vehicle by Model

Select by VIN

orEnter your VIN for the most accurate results.Enter your VIN for the most accurate results.

Select by Model

-- Select Make --

-- Select Model --

-- Select Year --

4 Clutch Discs found

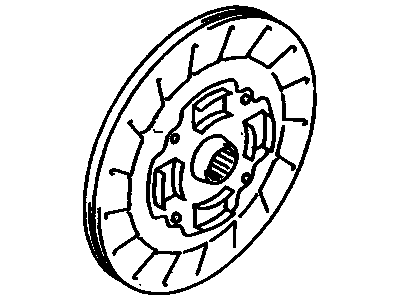

Pontiac Vibe Plate Asm,Clutch Driven

Part Number: 19205442- Other Name: PLATE, Engine Clutch Driven(Friction Disc); Disc

- Replaces: 88975263

$57.59 MSRP: $116.14You Save: $58.55 (51%)Pontiac Vibe Plate,Clutch Driven

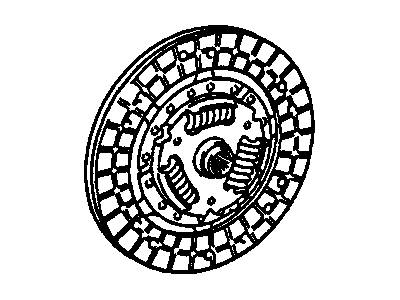

Part Number: 19184052- Other Name: PLATE, Engine Clutch Driven(Friction Disc); Disc

$123.08 MSRP: $194.53You Save: $71.45 (37%)Pontiac Vibe Plate,Clutch Driven

Part Number: 88974263- Other Name: PLATE, Engine Clutch Driven(Friction Disc)

- Replaces: 88973140

Pontiac Vibe Plate,Clutch Driven

Part Number: 88974436- Other Name: PLATE, Engine Clutch Driven(Friction Disc); Clutch, Disc

- Replaces: 94856035

Pontiac Vibe Clutch Disc Parts Questions & Answers

- Q: How to remove and install Clutch Disc,Pressure Plate and Release Bearing?A: Clutch components may be accessed by removing the transaxle, but the engine should not be removed unless it is being overhauled. In these cases, worn clutch components should be checked and replaced because their cost of replacement is much less than that of laborious access to them. Start with the release cylinder removal without hose disconnection when the engine remains in situ. After this, extract the transaxle out of the car providing assistance to the motor during removal either through an engine hoist or a jack under the engine with a piece of wood placed beneath to spread out loads. For now, keep the release bearing and release fork on the transaxle. To ease clutch disc removal, put a clutch alignment tool through its hub. Check for indexing marks on both flywheel and pressure plate; if they are missing, make scribe marks as guides for installation later on. Gradually loosen up bolts that hold together pressure plate and flywheel in a diagonal manner to relieve spring pressure and then take out bolts followed by pressure plate and clutch disc. Examine flywheel for any damage, so as to decide whether slight imperfections should be machined out at a machine shop. Evaluate thickness of clutch disc lining along with rivet condition and any signs of damage that might necessitate its replacement. Install new clutch discs alongside release bearings. Inspect machined surface of pressure plate as well as diaphragm spring fingers for any damages which can necessitate replacing entire assembly; you can remove minor glazing using emery cloth however. They do provide factory rebuilt units whenever getting another stock pressure plate is called for. Prior to installation, ensure oil-free surfaces on clean flywheels, pres-sure plates,and clutch discs handling them with clean hands all throughout. Place an alignment tool between the clutch disc and pressure plate before finger tightening bolts around it (Flynn & Rushing). Guide the alignment tool into position centralizing clutch disc between pressure plate bolts, and then tighten the bolts down in a crossover pattern to the specified torque. Take out alignment tool, apply high temperature grease onto inner groove of release bearing as well as contact areas of release lever and insert grease inside input-shaft bearing retainer from transaxle. Proceed to reinstall all of the following: clutch release bearing; transaxle; release cylinder; and every part previously taken off with all fasteners tightened to recommended torque specifications.