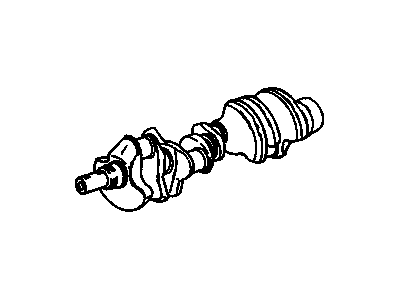

Your vehicle deserves only genuine OEM GM parts and accessories. To ensure reliability, purchase GM part # 10146900 Crankshafts. It is sometimes referred to as Buick Crankshaft. Our GM parts and accessories are expedited directly from authorized GM dealers strategically located all across the U.S. and are backed by the manufacturer's 12 month, 12,000 mile warranty. OEM GM parts are the best for restoring your vehicle to factory condition performance. This part fits specific Buick Century, Regal, Rendezvous models.

Affordable, reliable and built to last, GM part # 10146900 Crankshafts stands out as the smart option. GMPartsGiant.com is your prime online source with the biggest and best selection of genuine GM parts and accessories at giant discounted prices. We have the OEM GM parts and accessories you need at the wholesale prices. GMPartsGiant.com has you covered no matter what type of GM vehicle you drive. For detailed Buick parts information, click here.

×

My Garage

My Account

My Cart

Make sure this part fits your vehicle

Buick 10146900 Crankshafts

1989-2005 Buick

- Part DescriptionCrankshaft, Engine

- ManufacturerGeneral Motors

$455.59 MSRP: $723.33 1

You Save: $267.74 (38%)

Ships in 1-2 Business Days

Product Specifications

Brand Genuine Buick Manufacturer Part Number 10146900 Part Description Crankshaft, Engine Other Names Crankshaft Item Dimensions 9.8 x 9.1 x 23.4 inches Item Weight 43.10 Pounds Condition New Fitment Type Direct Replacement Manufacturer General Motors SKU 10146900 Warranty This genuine GM part is guaranteed by GM's factory warranty. Shipping & Return Shipping Policy Return Policy Warning: California’s Proposition 65Vehicle Fitment

Year Make Model Engine Important vehicle option details 1994-2005 Buick Century 6 Cyl 3.1L CUSTOM, CUSTOM 4 DOOR, CUSTOM STATION WAGON, GL, GLX, GS, LIMITED, LS, REGAL, SPECIAL, SPECIAL 4 DOOR, SPECIAL STATION WAGON 1989-2004 Buick Regal 6 Cyl 3.1L 2 DOOR, 4 DOOR, CUSTOM, CUSTOM 2 DOOR, CUSTOM 4 DOOR, GL, GLX, GRAN SPORT 2 DOOR, GRAN SPORT 4 DOOR, GS, LIMITED, LIMITED 2 DOOR, LIMITED 4 DOOR, LS, REGAL 2002-2005 Buick Rendezvous 6 Cyl 3.4L AWD, RENDEZVOUS 1994-1998 Buick Skylark 6 Cyl 3.1L 2 DOOR, 4 DOOR, CUSTOM 2 DOOR, CUSTOM 4 DOOR, GRAN SPORT 2 DOOR, GRAN SPORT 4 DOOR, LIMITED 2 DOOR, LIMITED 4 DOOR

Customer Questions & Answers

- Q:I am wonder if this is complete and correct part for my vehicle. Posted by GMPartsGiant Specialist

- A:You can Select Your Vehicle to check if 10146900 fits your vehicle.Posted by GMPartsGiant Specialist

- Q:How to inspect and repair a crankshaft? Posted by Customer

- A:Remove all burrs from the crankshaft oil holes using a stone, file, or scraper, chamfering the oil holes to remove sharp edges that might damage the new bearings. Check the main and connecting rod bearing journals for uneven wear, scoring, pits, and cracks. Rub a penny across each journal several times to assess its condition-if copper rubs off the penny and adheres to the crankshaft, the journals should be reground. Clean the crankshaft with solvent and dry it with compressed air, if available. Check the rest of the crankshaft for cracks and other damage, it should be magnafluxed to reveal hidden cracks-an automotive machine shop will handle this procedure. Measure the diameter of the main and connecting rod journals using a micrometer, taking measurements at multiple points around each journal's circumference to determine if it is out-of-round. If the crankshaft journals are damaged, tapered, out-of-round, or worn beyond the limits given in the specifications, have the crankshaft reground by an automotive machine shop. Check the oil seal journals at each end of the crankshaft for wear and damage. If the seal has worn a groove in the journal or if it is nicked or scratched, the new seal may leak when the engine is reassembled. In some cases, an automotive machine shop may be able to repair the journal by pressing on a thin sleeve. If repair is not feasible, a new or different crankshaft should be installed. If you are working on a Quad-4 engine, check the oil pump drive gear for wear and damage. If replacement is required, take the crankshaft to a dealer service department or an automotive machine shop. The old gear must be drilled and chiseled off, and the new gear must be heated in an oven prior to installation. Finally, examine the main and rod bearing inserts.Posted by GMPartsGiant Specialist

- Q:How to install the crankshaft? Posted by Customer

- A:The first step in engine reassembly is the installation of the crankshaft, assuming the prior cleaning, inspection, and potential repair or reconditioning of the engine block and crankshaft. With the engine positioned bottom-side up, remove the main bearing cap bolts and carefully lift out the caps, ensuring their proper order for later installation. If the original bearing inserts are still in place, remove them from the block and caps, then meticulously clean the bearing surfaces with a lint-free cloth. It's crucial to maintain spotless cleanliness during this process. The back sides of the new main bearing inserts should also be cleaned, with one insert placed in each main bearing saddle in the block and the other in the corresponding main bearing cap. The correct positioning of the grooved insert should be ensured in the block, and the tab on the bearing insert should align with the recess in the block or cap. The oil holes in the block must also align with those in the bearing inserts. The flanged thrust bearing is installed in the designated cap and saddle location, depending on the engine type. Following this, clean the faces of the bearings in the block and the crankshaft main bearing journals. Verify the cleanliness of the crankshaft, lay it carefully into position in the main bearings, and proceed to check the main bearing oil clearance. Plastigage is used to measure this clearance by placing pieces on each crankshaft main bearing journal and installing the caps without disturbing the Plastigage. Tighten the main bearing cap bolts in stages, working from the center main outward, taking care not to rotate the crankshaft. After removing the caps, compare the width of the crushed Plastigage to the scale provided to determine the main bearing oil clearance, ensuring it matches specifications. Any discrepancies may require different bearing inserts. If necessary, clean all traces of Plastigage material from the main bearing journals and bearing faces. For the final crankshaft installation, lift the crankshaft out of the engine, clean the bearing faces in the block, apply a uniform layer of moly-base grease or engine assembly lube to the bearing surfaces (including thrust faces), and lay the crankshaft back in place. Apply lubricant to the faces of the bearings in the caps and install them in their original locations with the arrows pointing forward. Secure the bolts, progressively tightening them, and tap the crankshaft ends gently to align the main bearing and crankshaft thrust surfaces. Retighten all main bearing cap bolts and rotate the crankshaft manually to check for any binding. Lastly, verify the crankshaft endplay with feeler gauges or a dial indicator, ensuring it meets specifications, and proceed to install the new rear main oil seal.Posted by GMPartsGiant Specialist

- Q:How to remove the crankshaft from an engine? Posted by Customer

- A:The crankshaft can only be removed after the engine has been removed from the vehicle. It is assumed that the flywheel or drive plate, crankshaft balancer/vibration damper, timing chain, oil pan, oil pump, and piston/connecting rod assemblies have already been removed. The rear main oil seal/housing (Quad-4 only) must be unbolted and separated from the block before proceeding with crankshaft removal. Before removing the crankshaft, check the endplay. Mount a dial indicator with the stem in line with the crankshaft and just touching one of the crank throws. Push the crankshaft all the way to the rear and zero the dial indicator. Next, pry the crankshaft to the front as far as possible and check the reading on the dial indicator. The distance it moves is the endplay. If it is greater than specified, check the crankshaft thrust surfaces for wear. If no wear is evident, new main bearings should correct the endplay. If a dial indicator is not available, feeler gauges can be used. Gently pry or push the crankshaft all the way to the front of the engine. Slip feeler gauges between the crankshaft and the front face of the thrust main bearing to determine the clearance. Check the main bearing caps to see if they are marked to indicate their locations. They should be numbered consecutively from the front of the engine to the rear. If they are not, mark them with number stamping dies or a center punch. Main bearing caps generally have a cast-in arrow, which points to the front of the engine. Loosen the main bearing cap bolts 1/4-turn at a time until they can be removed by hand. Note if any stud bolts are used and make sure they are returned to their original locations when the crankshaft is reinstalled. Gently tap the caps with a soft-face hammer, then separate them from the engine block. If necessary, use the bolts as levers to remove the caps. Try not to drop the bearing inserts if they come out with the caps. Carefully lift the crankshaft out of the engine. It may be a good idea to have an assistant available since the crankshaft is quite heavy. With the bearing inserts in place in the engine block and main bearing caps, return the caps to their respective locations on the engine block and tighten the bolts finger tight.Posted by GMPartsGiant Specialist

If you have any questions about this product, please don't hesitate to ask us. We will be happy to help you!

Genuine GM Part 10146900, the Right Choice

Why choose GM Parts Giant

- Dedicated Service

Your complete satisfaction is our #1 goal

- Lowest Prices

Best deals on genuine OE parts from dealerships

- Fast Delivery

Orders are processed and delivered promptly