My Garage

My Account

Cart

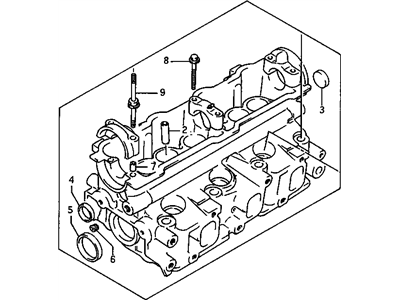

Genuine 1990 Chevrolet Metro Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

- Product Specifications

- Other Name: Head, Engine Cylinder; Cylinder Head

- Item Weight: 13.60 Pounds

- Item Dimensions: 13.9 x 8.8 x 7.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 96065427

- Warranty: This genuine part is guaranteed by GM's factory warranty.

1990 Chevrolet Metro Cylinder Head

We are your prime source for competitively priced and high-quality OEM 1990 Chevrolet Metro Cylinder Head. We provide you with parts that will allow you to save a lot of money without sacrificing quality. All our OEM parts are backed by the manufacturer's warranty and shipped out at a swift rate.

1990 Chevrolet Metro Cylinder Head Parts Questions & Experts Answers

- Q: What steps should be taken for thorough cleaning and inspection of the cylinder head and valve train components during an engine overhaul on 1990 Chevrolet Metro?A: Holding a cylinder head and checking valves needs proper cleaning and a complete look before choosing a plan for engine work. Wipe off all old gasket materials and sealing compound from where the head gasket meets the intake and exhaust manifolds, being very careful not to damage the head surface while cleaning. Get rid of scale clogging the coolant passages, then push a stiff brush through every hole to wipe away deposits. Wear your safety goggles and blow off debris with compressed air through each head threading hole to loosen sealant and rust. Do this while using the right size tap for each hole to clear away the removed material. Let the cylinder head dry completely by blowing solvent off with compressed air. Chemical cleaning for car parts works well but needs careful use. Soak the camshaft, rocker arms, and rocker shafts with solvent, then dry them all on site, making sure you never confuse them by mistake. Fix each valve spring, spring seat, keeper, and retainer separately to prevent parts from getting mixed up. Also scrape off any heavy debris from your engine valves using a drill-powered wire brush on both the valve head and stem. Look for cracks and leaky coolant in the head, and talk to machine shop experts when needed. Verify the condition of the head gasket mating surface, the mating surface for intake and exhaust manifolds, by running a smooth metal ruler along them and gauging gaps with a thin metal strip. Also examine valve seats for surface damage such as cracks, holes, or fire scarring. Check your valve stem movement against the guide with a plain dial indicator, and get help from an automotive machine shop if you're uncertain about valve guide condition. Check each valve's flat surface for uneven wear, shape problems, cracks, holes, and fire damage. Also look for scraping and scuffing on the valve stem. Replace any valves that have margin less than the required width on their surface. Measure valve spring free length, look for pits and wear, and send them to a machine shop to test tension against technical standards. Place the springs flat on a surface to check they stay right-angled and straight, throw away those that are bent or turning downwards. Make sure to change any damaged parts in the spring retainers and keepers before letting your engine run to avoid significant issues.