My Garage

My Account

Cart

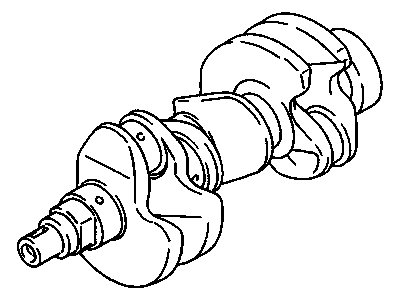

Genuine 1991 Chevrolet Metro Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

- Product Specifications

- Other Name: Crankshaft, Engine; Crankshaft

- Replaces: 96051626

- Item Weight: 13.20 Pounds

- Item Dimensions: 19.0 x 8.4 x 6.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 96055086

- Warranty: This genuine part is guaranteed by GM's factory warranty.

1991 Chevrolet Metro Crankshaft

We are your prime source for competitively priced and high-quality OEM 1991 Chevrolet Metro Crankshaft. We provide you with parts that will allow you to save a lot of money without sacrificing quality. All our OEM parts are backed by the manufacturer's warranty and shipped out at a swift rate.

1991 Chevrolet Metro Crankshaft Parts Questions & Experts Answers

- Q: How can you ensure the crankshaft oil holes are properly prepared and the crankshaft is in good condition before reassembly on 1991 Chevrolet Metro?A: Remove all burrs from the crankshaft oil holes using a stone, file, or scraper to ensure the oil holes are chamfered, preventing sharp edges from gouging or scratching the new bearings. Clean the crankshaft with solvent and dry it with compressed air if available, ensuring to clean the oil holes with a stiff brush and flush them with solvent. Check the main and connecting rod bearing journals for uneven wear, scoring, pits, and cracks. Rub a penny across each journal several times; if copper rubs off and embeds in the crankshaft, the journals should be reground, indicating roughness. Inspect the rest of the crankshaft for cracks and other damage, utilizing magnafluxing to reveal hidden cracks, which can be handled by an automotive machine shop. Measure the diameter of the main and connecting rod journals with a micrometer, comparing the results to the specifications, and check at several points to detect taper and out-of-round conditions. If the journals are damaged, tapered, out-of-round, or worn beyond the specified limits, have the crankshaft reground by an automotive machine shop, ensuring the correct size bearing inserts are used if reconditioned. Inspect the oil seal journals at each end of the crankshaft for wear and damage; if grooves, nicks, or scratches are present, the new seals may leak upon reassembly. In some cases, an automotive machine shop may repair the journal by pressing on a thin sleeve, but if repair isn't feasible, a new or different crankshaft should be installed. Finally, examine the main and rod bearing inserts.