My Garage

My Account

Cart

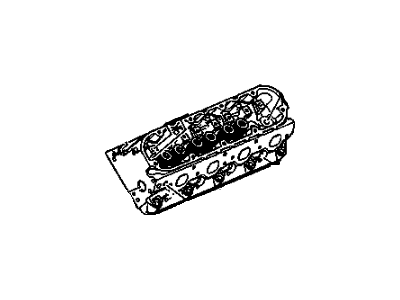

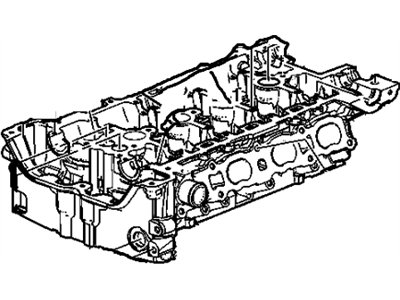

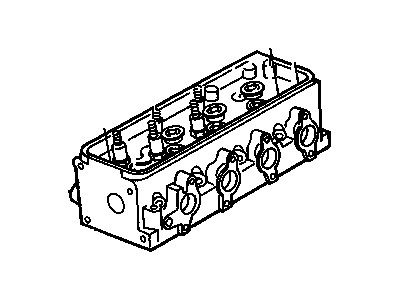

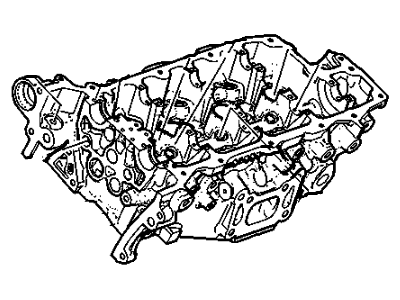

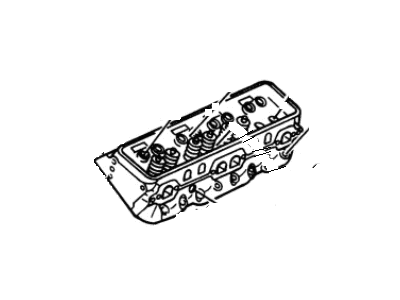

Genuine Buick Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

79 Cylinder Heads found

Buick Head Assembly, Cyl (W/ Valve)

Part Number: 12629058$1284.58 MSRP: $2048.32You Save: $763.74 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: HEAD, Engine Cylinder; Cylinder Head

- Replaced by: 12746921

Buick Head Assembly, Cyl (W/ Vlv)

Part Number: 12703173$814.67 MSRP: $1213.00You Save: $398.33 (33%)Product Specifications- Other Name: Cylinder Head

- Replaces: 55587168, 55573010

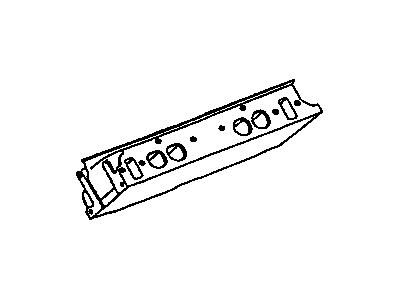

Buick Cylinder Head Assembly (Machining) (Lh Lfx W/Sai)

Part Number: 12633962$245.95 MSRP: $389.66You Save: $143.71 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (Machining) (Lh Lfx W/Sai) ; Head, Engine Cylinder; Cylinder Head

Buick Head Assembly,Cyl (Remanufacture) 2012, 2017 Llt Rh

Part Number: 19329674$1650.00 MSRP: $2728.26You Save: $1078.26 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly,Cyl (Reman) 2012, 2017 Llt Rh

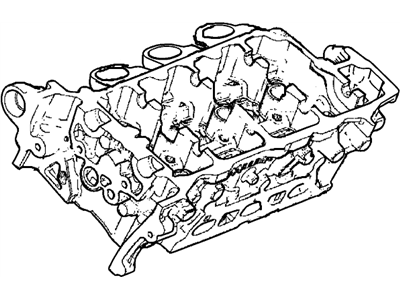

Buick Cylinder Head Assembly With Valve

Part Number: 12684222$721.27 MSRP: $1193.49You Save: $472.22 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Vlv); Cylinder Head

- Replaces: 12668131

- Product Specifications

- Other Name: Cylinder Head

- Replaces: 12679109, 12679457, 12677521, 12668132, 12673745

Buick Cylinder Head Assembly (Machining)

Part Number: 12608280$702.44 MSRP: $1428.81You Save: $726.37 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (Machining); Cylinder Head

- Replaces: 12634128

Buick Cylinder Head Assembly With Valve

Part Number: 55504792$596.76 MSRP: $987.68You Save: $390.92 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Vlv); Cylinder Head

- Replaced by: 12729488

Buick Cylinder Head Assembly (Machining)

Part Number: 12626381$503.19 MSRP: $832.81You Save: $329.62 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (Machining); Cylinder Head

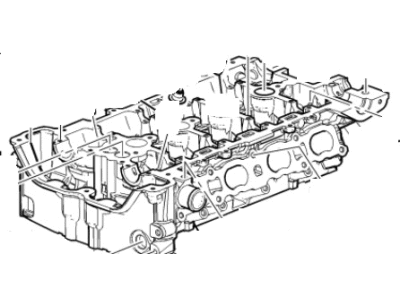

Buick Head Assembly, Cyl (W/ Vlv)

Part Number: 12690428$1076.04 MSRP: $1713.67You Save: $637.63 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 12686739, 12626883, 12680551

Buick Head Assembly,Cyl (Remanufacture) 2008, 2010 Llt Rh

Part Number: 19329668$950.75 MSRP: $1570.63You Save: $619.88 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly,Cyl (Reman) 2008, 2010 Llt Rh

Buick Head Assembly,Cyl (Reman) 2012, 2017 Llt Lh

Part Number: 19329673$1586.73 MSRP: $2528.17You Save: $941.44 (38%)Ships in 1-3 Business DaysBuick Engine Cylinder Head (W/Valve)

Part Number: 12360424$1008.05 MSRP: $1303.23You Save: $295.18 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl(W/Valve); Cylinder Head

Buick Head Assembly,Cyl (Remanufacture) 2008, 2010 Llt Lh

Part Number: 19329667$798.90 MSRP: $1319.64You Save: $520.74 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly,Cyl (Reman) 2008, 2010 Llt Lh

Buick Engine Cylinder Head (W/Vlvs)

Part Number: 12635548$299.00 MSRP: $474.37You Save: $175.37 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl (W/Vlvs); Cylinder Head

- Replaces: 12634229, 12629455, 12634227

- Product Specifications

- Other Name: Head Kit, Cyl; Cylinder Head

- Product Specifications

- Other Name: Head,Cyl (W/Studs); Cylinder Head

Buick Head Assembly, Cyl (W/ Vlv)

Part Number: 12690422$796.64 MSRP: $1027.88You Save: $231.24 (23%)Product Specifications- Other Name: Cylinder Head

- Replaces: 12686736, 12648916, 12627152, 12680557, 12666599

- Product Specifications

- Other Name: Head Assembly, Cyl (Machining); Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

| Page 1 of 4 |Next >

1-20 of 79 Results

Buick Cylinder Head

Our platform hosts an impressive inventory of OEM Buick Cylinder Heads. Just to let you know, all our genuine Buick Cylinder Heads are backed by the manufacturer's warranty and are offered at unbeatable prices. Enjoy a smooth shopping experience with our easy return policy and fast delivery service.

Buick Cylinder Head Parts Questions & Experts Answers

- Q: How to assemble a Cylinder Head on Buick Skylark?A:Check that all subassemblies of the valve mechanism are cleaned and dematted, and that the bare cylinder head is free of carbon and dirt itself and also reamed or ground for valves. Place a valve in the correct port and install the valve spring set of that cylinder comprising of the spring, damper, shield as well as the cap. Place the valve spring compressor of the assembly over the valve stem and compress it. It is worth to insert a new oil seal with the flat side downwards, and it must not be twisted. Next is to put the valve locks and release the compressor and ensure that the lock rests well on the upper part of the valve stem. Measure the installed height of the valve springs with a narrow, thin scale; measure from the top of the shim or spring seat to the top of the valve spring or spring shield. If needed, place up to 1/16 th inch thick shim under the valve spring to build the required thickness; nevertheless, do not shim down to a height that is thinner than the specified minimum length of the spring; if this happens, get a new spring. Last of all, inspect each of the twenty stems for oil leaks using a vacuum test simply because if the seal is installed correctly, it should not cause any vacuum leakage.

Related Buick Parts

Browse by Model

Allure Cylinder Head Cascada Cylinder Head Century Cylinder Head Electra Cylinder Head Enclave Cylinder Head Encore Cylinder Head Encore GX Cylinder Head Envision Cylinder Head Envista Cylinder Head Estate Wagon Cylinder Head LaCrosse Cylinder Head Lesabre Cylinder Head Lucerne Cylinder Head Park Avenue Cylinder Head Rainier Cylinder Head Reatta Cylinder Head Regal Cylinder Head Rendezvous Cylinder Head Riviera Cylinder Head Roadmaster Cylinder Head Skyhawk Cylinder Head Skylark Cylinder Head Somerset Cylinder Head Terraza Cylinder Head Verano Cylinder Head