My Garage

My Account

Cart

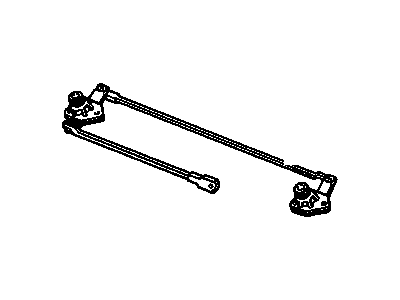

Genuine Cadillac Deville Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

39 Transmission Assemblies found

Cadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (04Ajn)

Part Number: 19178290$368.81 MSRP: $2836.88You Save: $2468.07 (87%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (05Mmn)

Part Number: 19178296$612.81 MSRP: $2836.88You Save: $2224.07 (79%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (98Bsn)

Part Number: 19178260$362.04 MSRP: $2836.88You Save: $2474.84 (88%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (93Bcn)

Part Number: 19178242$362.04 MSRP: $2836.88You Save: $2474.84 (88%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (05Ajn)

Part Number: 19178294$366.63 MSRP: $2836.88You Save: $2470.25 (88%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (96Mln)

Part Number: 19178254$1760.95 MSRP: $2836.88You Save: $1075.93 (38%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (98Cln)

Part Number: 19178262$1760.95 MSRP: $2836.88You Save: $1075.93 (38%)Ships in 1-2 Business DaysCadillac Deville Transaxle Asm, Auto (Goodwrench Remanufacture) (98Crn) Export

Part Number: 19178261

| Page 1 of 2 |Next >

1-20 of 39 Results

Cadillac Deville Transmission Assembly

Each OEM Cadillac Deville Transmission Assembly we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Deville Transmission Assembly Parts Questions & Experts Answers

- Q: How to remove and install a transmission assembly for major repair work on Cadillac DeVille?A:If the transaxle requires major repair work, it should be left to a dealer service department or an automotive or transmission repair shop. If you've decided that the transaxle must be removed for overhaul or major repair work, several preliminary steps should be taken. Read all removal and installation procedures carefully prior to committing this job. Transaxle removal involves removing the engine and transaxle as an assembly. For removal, first, drain the transaxle fluid. Then, remove the engine/transaxle assembly, and separate the transaxle from the engine. For installation, it is the reverse of removal, noting the following points: Prior to installation, make sure the torque converter is fully engaged in the transmission. To do this, rotate the converter while pushing it towards the transaxle. If it wasn't already fully in place, you'll feel it "clunk" into position as it engages with the input shaft and front pump. It may even "clunk" more than once. Lubricate the torque converter hub with multi-purpose grease. Move the transaxle forward carefully until the dowel pins and the torque converter are engaged. Make sure the marks on the torque converter and drive plate are in alignment. Install the transaxle-to-engine bolts. Tighten the bolts to the specified specific torque. Install the engine/transaxle assembly. Lower the vehicle. Install and adjust the Shift Cable. Fill the transaxle with the recommended type and amount of fluid, run the vehicle and check for fluid leaks.

Related Cadillac Deville Parts

Browse by Year

2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly 1994 Transmission Assembly 1990 Transmission Assembly 1989 Transmission Assembly 1988 Transmission Assembly 1987 Transmission Assembly 1986 Transmission Assembly 1985 Transmission Assembly