My Garage

My Account

Cart

Genuine Cadillac DTS Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Engine Mounts found

Cadillac DTS Strut Assembly, Engine Mount

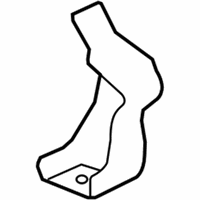

Part Number: 20760911$42.73 MSRP: $73.70You Save: $30.97 (43%)Cadillac DTS Bracket, Engine Lift Rear

Part Number: 12562855$5.97 MSRP: $9.83You Save: $3.86 (40%)Ships in 1-2 Business DaysCadillac DTS Mount Assembly, Engine Front

Part Number: 20760905$138.11 MSRP: $218.28You Save: $80.17 (37%)

Cadillac DTS Engine Mount

Each OEM Cadillac DTS Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac DTS Engine Mount Parts Questions & Experts Answers

- Q: What should be done if engine mounts are broken or deteriorated in 4.6L V8 engine on Cadillac DTS?A:Engine mounts need replacement only if they break or deteriorate because damages to driveline components become inevitable. The 4.6L VB engine utilizes four main engine/transaxle mounts together with front and passenger side engine mounts and two transaxle/subframe mounts at the rear and left side established for vehicles starting from 2000. An engine inspection requires minor engine elevation to reduce weight on mounts while looking for cracks, hardened rubber and separation between metal plates in addition to monitoring the relation between mount plates and engine or frame frameworks. Detecting mount movement requires lowering the engine after fastening its elements securely. The application of rubber preservative helps to delay the deterioration process. Vehicle replacement starts with disconnecting the negative battery terminal cable then placing supporting jackstands under the vehicle before removing torque struts and cooling fans if present. First install an engine support fixture while you detach the front mount from both engine and subframe then remove the front brace bolts connecting to the cylinder head. Rise the engine to expose the subframe clearance around the motor mount stud(s) before removing the front engine mount but always apply threadlocking compound for reinstallation. The right side mount installation requires you to follow a matched approach that includes engine support fixture application while removing necessary components. Each production year for Toyota Tundra uses different approaches to position its subframe/transaxle mounts which the left front mount connects to the transaxle near the frame and the rear mount connects to the transaxle and subframe. The procedure involves disconnection of the mount from the transaxle and subframe/bracket with torque struts removed and an engine support fixture installed while raising the engine if necessary to detach front subframe/transaxle mount(s) before reinstallation with thread locking compound application. Engine torque strut mounts on the upper radiator support can be replaced without engine lifting by first removing both through-bolts and bolts that secure the strut to its mounts. Through-bolt alignment requires a prybar for the installation process. Before final tightening of the torque strut installation make sure the engine/transaxle assembly stays in its position with no lifting devices present while using thread-locking compound on the threads.