My Garage

My Account

Cart

Genuine Cadillac Escalade Spark Plug Wires

Spark Plug Ignition Wires- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Spark Plug Wires found

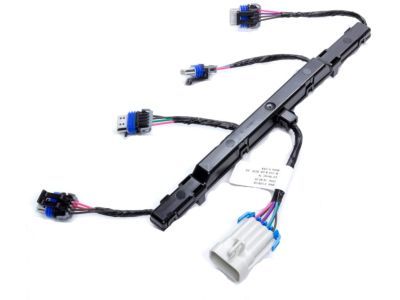

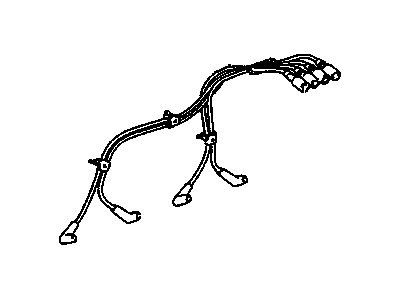

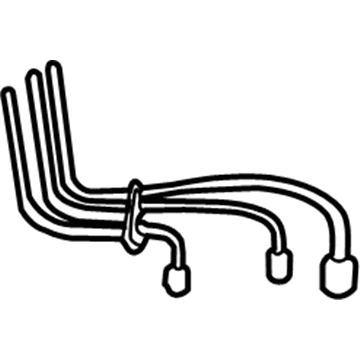

Cadillac Escalade Spark Plug Wire Kit

Part Number: 19351572$83.36 MSRP: $157.28You Save: $73.92 (47%)Ships in 1-2 Business DaysCadillac Escalade Wire Assembly, Ignition Coil

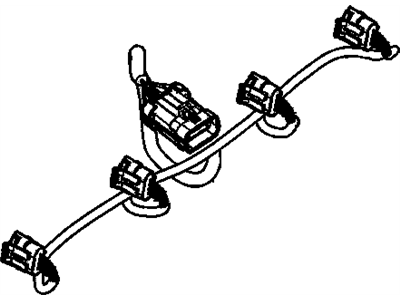

Part Number: 12579355$114.53 MSRP: $248.98You Save: $134.45 (54%)Ships in 1-2 Business DaysCadillac Escalade Wire Assembly, Ignition Coil

Part Number: 12601824$126.87 MSRP: $275.85You Save: $148.98 (55%)Ships in 1 Business DayCadillac Escalade Wire Asm,Spark Plug

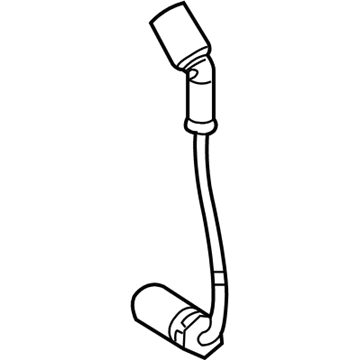

Part Number: 19351578$12.94 MSRP: $28.54You Save: $15.60 (55%)Cadillac Escalade Wire Asm,Spark Plug #5 Cyl

Part Number: 19351564$13.00 MSRP: $40.73You Save: $27.73 (69%)Cadillac Escalade Wire,Spark Plug

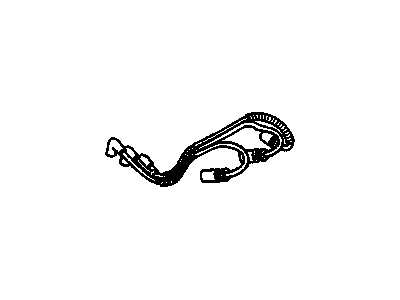

Part Number: 12192133$15.17 MSRP: $28.62You Save: $13.45 (47%)Ships in 1-2 Business DaysCadillac Escalade Shield,Spark Plug Wire

Part Number: 19329681$6.82 MSRP: $12.86You Save: $6.04 (47%)Ships in 1-2 Business DaysCadillac Escalade WIRE SET-SPLG

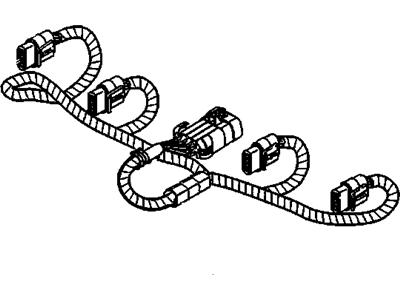

Part Number: 12731654$99.33 MSRP: $215.92You Save: $116.59 (54%)Ships in 1-3 Business DaysCadillac Escalade WIRE KIT,SPLG

Part Number: 19417606$71.14 MSRP: $154.66You Save: $83.52 (54%)Ships in 1 Business DayCadillac Escalade WIRE KIT,SPLG

Part Number: 19417605$122.66 MSRP: $266.64You Save: $143.98 (54%)Ships in 1-2 Business DaysCadillac Escalade WIRE KIT,SPLG

Part Number: 19417608$83.01 MSRP: $180.45You Save: $97.44 (54%)Ships in 1-2 Business DaysCadillac Escalade Spark Plug Wire Kit

Part Number: 88892832$139.27 MSRP: $302.76You Save: $163.49 (54%)Ships in 1-2 Business DaysCadillac Escalade Wire Assembly, Splg

Part Number: 12716289$17.45 MSRP: $32.93You Save: $15.48 (48%)Ships in 1 Business DayCadillac Escalade WIRE ASM-SPLG

Part Number: 12731653$36.24 MSRP: $68.38You Save: $32.14 (47%)Ships in 1-2 Business DaysCadillac Escalade WIRE KIT,SPLG

Part Number: 19417612$98.59 MSRP: $214.32You Save: $115.73 (54%)Ships in 1 Business DayCadillac Escalade WIRE KIT,SPLG

Part Number: 19417609$127.98 MSRP: $241.44You Save: $113.46 (47%)Ships in 1-2 Business DaysCadillac Escalade Wire Asm,Spark Plug #4 Cyl

Part Number: 19351562$20.41 MSRP: $38.49You Save: $18.08 (47%)Ships in 1-2 Business DaysCadillac Escalade Wire Asm,Spark Plug #3 Cyl

Part Number: 19351560$17.21 MSRP: $32.52You Save: $15.31 (48%)Ships in 1-2 Business DaysCadillac Escalade Wire Asm,Spark Plug #1 Cyl

Part Number: 19351565$21.28 MSRP: $40.15You Save: $18.87 (47%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 30 Results

Cadillac Escalade Spark Plug Wires

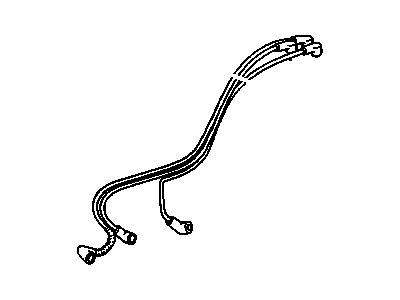

Spark Plug Wires is in charged with the responsibility of transmitting high voltage from the ignition coil to the spark plugs required to start the engine in Cadillac Escalade vehicles. These wires are commonly called high tension leads and are manufactured using thick, flexible, heat resisting conductor insulation in order to minimize arc levels and enhance the material's longevity. Cadillac Escalade Spark Plug Wiress are made in such a way that they are cut to the right length with metal terminals to fit properly and modern models comes with Spark Plug Wires technologies that help to reduce RFI. Over the years, Cadillac Escalade models have gone through changes on Spark Plug Wires used in the new models and the latest paradigm is coil packs or individual ignition coils normally fixed directly to the spark plugs thus eliminating the wire. This change boosts the efficiency, and durability of the engine, thus the need to ensure that Cadillac Escalade Spark Plug Wires is well maintained for optimum performance.

Each OEM Cadillac Escalade Spark Plug Wires we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Spark Plug Wires Parts Questions & Experts Answers

- Q: How should spark plug wires be checked and maintained on Cadillac Escalade?A:The Spark Plug wires should be checked at recommended intervals and whenever new spark plugs are installed in the engine, with V6 engines having wires that extend from the spark plugs to an ignition coil assembly, while V8 engines feature individual coils for each cylinder and shorter wires. Begin by visually inspecting the spark plug wires while the engine runs in a darkened garage with adequate ventilation, observing for arcing or small sparks at any damaged areas. Disconnect a plug wire from one spark plug by gripping the rubber boot, twisting slightly, and pulling it free without tugging on the wire itself; a boot pulling tool can be useful. Inspect the inside of the boot for corrosion, which appears as a white crusty powder, and ensure the wire fits tightly onto the spark plug, using pliers to crimp the metal connector if necessary. Clean the entire length of the wire with a rag to remove dirt and grease, checking for holes, burns, cracks, and other damage while avoiding excessive bending. Disconnect the wire from the coil by pulling it straight out, again only using the rubber boot, and check for corrosion and fit before reattaching it. Repeat the process for the remaining spark plug wires, ensuring they are securely fastened at both ends. If new wires are needed, purchase a set specific to the engine model, which typically comes pre-cut with installed rubber boots, and replace them one at a time to maintain the correct firing order, taking care to note the routing of each wire, especially on V6 engines where ignition wire loom clamps must be released and re-secured.

Related Cadillac Escalade Parts

Browse by Year

2024 Spark Plug Wires 2023 Spark Plug Wires 2022 Spark Plug Wires 2021 Spark Plug Wires 2020 Spark Plug Wires 2019 Spark Plug Wires 2018 Spark Plug Wires 2017 Spark Plug Wires 2016 Spark Plug Wires 2015 Spark Plug Wires 2014 Spark Plug Wires 2013 Spark Plug Wires 2012 Spark Plug Wires 2011 Spark Plug Wires 2010 Spark Plug Wires 2009 Spark Plug Wires 2008 Spark Plug Wires 2007 Spark Plug Wires 2006 Spark Plug Wires 2005 Spark Plug Wires 2004 Spark Plug Wires 2003 Spark Plug Wires 2002 Spark Plug Wires 2000 Spark Plug Wires 1999 Spark Plug Wires