My Garage

My Account

Cart

Genuine Chevrolet Astro Spark Plug Wires

Spark Plug Ignition Wires- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 Spark Plug Wires found

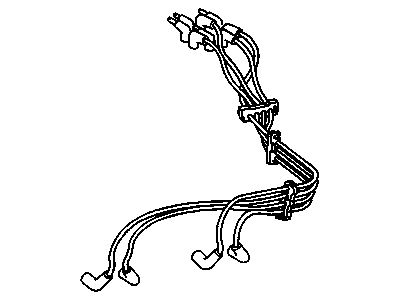

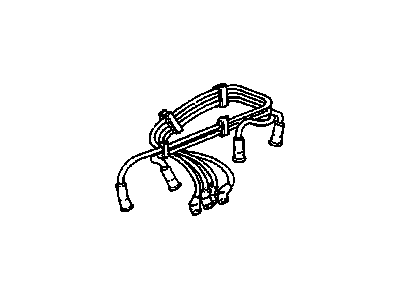

Chevrolet Astro Spark Plug Wire Kit

Part Number: 19154583$47.04 MSRP: $102.26You Save: $55.22 (54%)Ships in 1-2 Business DaysChevrolet Astro Wire Asm,Spark Plug #5 Cyl

Part Number: 19351564$13.00 MSRP: $40.73You Save: $27.73 (69%)Chevrolet Astro WIRE KIT,SPLG

Part Number: 19433890$106.38 MSRP: $231.26You Save: $124.88 (54%)Ships in 1-3 Business DaysChevrolet Astro Spark Plug Wire Kit

Part Number: 19154585$97.40 MSRP: $183.78You Save: $86.38 (47%)Ships in 1-2 Business DaysChevrolet Astro Wire Asm,Spark Plug #4 Cyl

Part Number: 19351562$20.41 MSRP: $38.49You Save: $18.08 (47%)Ships in 1-2 Business DaysChevrolet Astro Wire,Spark Plug #6 Cyl

Part Number: 12173581$20.13 MSRP: $37.98You Save: $17.85 (47%)Ships in 1-2 Business DaysChevrolet Astro Spark Plug Wire Kit

Part Number: 12043816$30.16 MSRP: $64.04You Save: $33.88 (53%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 37 Results

Chevrolet Astro Spark Plug Wires

Spark Plug Wires in Chevrolet Astro vehicle is an essential component of the car's ignition system because it conducts high voltage from the ignition coil to spark plugs so that the fuel mix inside the combustion chamber of the car engine can be ignited efficiently. These wires also referred to as high tension leads are very thick with a high heat resistant layer on their outer layers to minimize arcing and increase the lifespan of the wires. They are cross-sectioned accurately, and come with metal ends for making strong connections. Throughout its production from 1985 to 2005, Chevrolet Astro car produced different styles of the Spark Plug Wires depending on the changes that occurred in the engines. Earlier designs featured a coil wire but present generation vehicles incorporate coil packs or each cylinder ignition coil therefore the application of traditional Spark Plug Wires is limited. The main difference between these types of engines can be found in their design and in the technology that has been integrated to reduce RF interferences so that the engine will run as efficiently and for as long as possible.

Each OEM Chevrolet Astro Spark Plug Wires we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Astro Spark Plug Wires Parts Questions & Experts Answers

- Q: How should spark plug wires be checked and maintained for proper engine operation on Chevrolet Astro?A:The Spark Plug wires should be examined at appropriate interval and also whenever there is replacement of spark plugs in the engine. It is crucial for the functioning of the engine that the wires are not mixed, so examine the wires as each is different. When removing the plug wire from a spark plug, take the rubber end by holding it by the screw, twist it a little and pull it off, do not pull on the wire. Ensure within the boot for corrosion; corrosion has the appearance of a white crusty powder and push the wire and boot in place over the spark plug but only lightly. If it is not, then pull out the wire and with the use of pliers, he needs to squeeze the actual metal connector that is within the boot until it can finally slide. Wash the surface area of the wire by sweeping it with a clean piece of cloth and then examine it for such things as holes, burnt surface, cracks and other imperfections which are occasioned by over bending of the wire; a factor that results into the breaking of the conductor within the wire. Remove the wire from the spark plug Distributor Cap perhaps with a detachment of a retaining ring upward, and just again pull the rubber insulator. Be sure there is no sign of corrosion and that the fit is snug, as with the spark plug end; then check the spark plug wire's resistance with an ohmmeter and reconnect it to the distributor cap. The last check is done for the remaining spark plug wires and this is done by making sure that they fit tightly at the distributor end and also at the spark plug side. If new spark plug wires are called for, always get the ones that fit your engine model which normally comes pre-spliced with rubber-go-throughs. Disconnect wires one at a time so that there will be confusion when reconnecting in the correct firing order, and ensure to take note of the routing of each wire before disconnecting it.

Related Chevrolet Astro Parts

Browse by Year

2005 Spark Plug Wires 2004 Spark Plug Wires 2003 Spark Plug Wires 2002 Spark Plug Wires 2001 Spark Plug Wires 2000 Spark Plug Wires 1999 Spark Plug Wires 1998 Spark Plug Wires 1997 Spark Plug Wires 1996 Spark Plug Wires 1995 Spark Plug Wires 1994 Spark Plug Wires 1993 Spark Plug Wires 1992 Spark Plug Wires 1991 Spark Plug Wires 1990 Spark Plug Wires 1989 Spark Plug Wires 1988 Spark Plug Wires 1987 Spark Plug Wires 1986 Spark Plug Wires 1985 Spark Plug Wires