My Garage

My Account

Cart

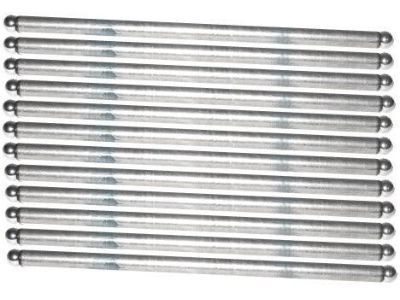

Genuine Chevrolet Beretta Pushrod

Valve Push Rod- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Pushrods found

Chevrolet Beretta Rod Assembly, Valve Push (144Mm) *Yellow Inside Diameter

Part Number: 10166354$3.98 MSRP: $6.27You Save: $2.29 (37%)Chevrolet Beretta Rod Assembly, Valve Push (152Mm) *Gree*Green Inside Diameter

Part Number: 10166355$3.94 MSRP: $6.20You Save: $2.26 (37%)

Chevrolet Beretta Pushrod

Each OEM Chevrolet Beretta Pushrod we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Beretta Pushrod Parts Questions & Experts Answers

- Q: How to remove and install the Pushrod and rocker arm in V6 engine on Chevrolet Beretta?A:Firs remove the rocker arm covers by removing one rocker arm mounting nut at a time and then disconnecting rocker arms, nuts, and pivot balls. Keep each set of rocker arm components in separate plastic bags with labels. In case you just want to take out the pushrods, make sure that you loosen the rocker arm nuts and turn rocker arms for pushrod removal clearance. Pull the pushrods out and store them separately. Check all rocker arms for wearing, cracking or other damage particularly where valve stems come into contact with pushrods. Examine galls in each rocker arm pivot seat and faces of pivot ball for stress cracks or unusual wear patterns. Get rid of old or damaged rocker arms, replacing them with new ones while also fixing new pivot balls. The hole must be open at the end of each rocker arm next to the push rod. Push rods should be examined at their ends for fractures and excessive wear. Bend test each pushrod over glass plate. Apply lubricant to lower ends of all pushrods before reinstalling them at their original locations ensuring they bottom out in lifter socket. Grease the upper ends of valve stems as well as ends of the pushrods on lifter side. Grease also should be applied on ball pivots so as not to damage them before tightening the nuts which hold down the rocker arms, pivot balls and nuts (and ensuring that they engage properly). Finally install the rockers cover.