My Garage

My Account

Cart

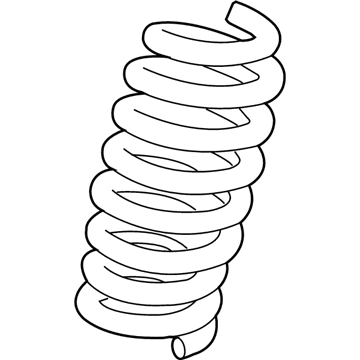

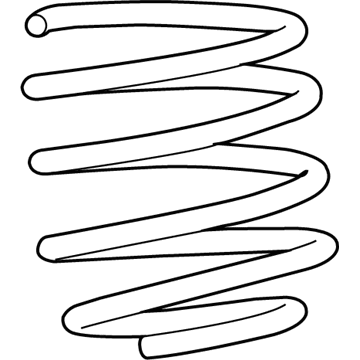

Genuine Chevrolet Camaro Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

50 Coil Springs found

Chevrolet Camaro Rear Coil Spring

Part Number: 23341860$37.38 MSRP: $70.53You Save: $33.15 (47%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84186923$37.31 MSRP: $70.40You Save: $33.09 (47%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84186930$43.98 MSRP: $82.99You Save: $39.01 (48%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 23136675$35.75 MSRP: $67.44You Save: $31.69 (47%)Ships in 1-3 Business DaysChevrolet Camaro Spring, Front Coil

Part Number: 84384681$45.30 MSRP: $85.48You Save: $40.18 (48%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84186929$43.15 MSRP: $81.41You Save: $38.26 (47%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84186928$36.94 MSRP: $69.70You Save: $32.76 (47%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84384683$44.33 MSRP: $83.64You Save: $39.31 (47%)Ships in 1-3 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84186921$41.29 MSRP: $80.52You Save: $39.23 (49%)Ships in 1-2 Business DaysChevrolet Camaro Front Coil Spring

Part Number: 84312736$43.87 MSRP: $82.78You Save: $38.91 (47%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 23341853$35.84 MSRP: $67.64You Save: $31.80 (48%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 84079567$36.63 MSRP: $66.59You Save: $29.96 (45%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 84010830$37.32 MSRP: $67.86You Save: $30.54 (45%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 23341851$36.11 MSRP: $68.15You Save: $32.04 (48%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 84213498$31.96 MSRP: $58.09You Save: $26.13 (45%)Ships in 1-3 Business DaysChevrolet Camaro Rear Coil Spring

Part Number: 23341852$38.79 MSRP: $70.53You Save: $31.74 (45%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 50 Results

Chevrolet Camaro Coil Springs

Coil springs located in Chevrolet Camaro automobile are suspension system parts meant for maintaining steadiness of the car upon the contact with irregularities of roads. Each wheel has a coil spring that assist in managing the condition of the vehicle and also its comfort during operation. These springs are made from flexible materials which form a coil, they can easily be extended or compressed to their normal size owing to this feature. In this car, the different types of spring construction that has been employed include the compression spring that is used to resist the force which tends to compress it. The performance of these coil springs depends on its spring rate, which is the amount of load needed to compress them through a certain distance. It enables Coil Springs Chevrolet Camaro manufacturers to design their products in several ways to improve performance and absorption of forces in any terrain.

Each OEM Chevrolet Camaro Coil Springs we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Coil Springs Parts Questions & Experts Answers

- Q: Is a spring compressor necessary for the procedure involving Coil Springs and Shock Absorber assembly replacement on Chevrolet Camaro?A:This is a tedious process, which requires the use of a spring compressor, available for a one day hire from most auto parts stores or equipment yards. Should the struts or coil springs reveal signs of fatigue such as, leaking fluid, loss of damping or mechanical damage, do not carry out any work without getting advice first as the strut/coil spring assemblies cannot be refurbished; they must be replaced. Coil spring strut assemblies might be purchased readily on an exchange basis which should save time and effort; it is advisable to find out the cost and availability of components in advance. Strut disassembly particularly of the upper and lower part may involve risks such as serious injury occasionally when working on the assembly. Before doing this make sure to use only the best spring compressor and make sure to follow all the instructions that come with the spring compressor. When you have departed with the coil spring from the strut assembly, set it aside in a safe place. Drive out the strut and spring assembly as shown in Fig. 3, with the strut clevis bracket jammed in a vise. As per the tool manufacturer's instructions, the spring compressor has to be fitted on the spring and the spring compressed until there is no pressure on the upper spring seat which can be checked by shaking the spring. With the help of Torx bit, lock the damper shaft from rotating and then unscrew the damper shaft nut, and then remove nut, upper mount retainers, mount, insulator and bumper but before this arrange them in the manner how they are removed. Check for wear and tear in the rubber part of your upper mount, when they get weak see a mechanic to replace them. Carefully remove the compressed spring from the assembly and put in a secured position, if two springs are dismantled label them as LEFT and RIGHT. The lower insulator must be taken off, and if it is damaged it has to be replaced. To be disassembled, retract the damper shaft and take out the rubber bump stop, then remove the lower insulator. A lower seat is now provided with a compressed coil spring, the end of which is to be seated against the raised stop. The upper mount and retainers should then be installed as well as the damper shaft nut which is to be tightened to the prescribed torque; the spring compressor tool must then be removed before the strut/spring assembly is installed.

Related Chevrolet Camaro Parts

Browse by Year

2024 Coil Springs 2023 Coil Springs 2022 Coil Springs 2021 Coil Springs 2020 Coil Springs 2019 Coil Springs 2018 Coil Springs 2017 Coil Springs 2016 Coil Springs 2015 Coil Springs 2014 Coil Springs 2013 Coil Springs 2012 Coil Springs 2011 Coil Springs 2010 Coil Springs 2002 Coil Springs 2001 Coil Springs 2000 Coil Springs 1999 Coil Springs 1998 Coil Springs 1997 Coil Springs 1996 Coil Springs 1995 Coil Springs 1994 Coil Springs 1993 Coil Springs 1992 Coil Springs 1991 Coil Springs 1990 Coil Springs 1989 Coil Springs 1988 Coil Springs 1987 Coil Springs 1986 Coil Springs 1985 Coil Springs 1984 Coil Springs 1983 Coil Springs 1982 Coil Springs