My Garage

My Account

Cart

Genuine Chevrolet Camaro Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Flywheels found

Chevrolet Camaro Automatic Transmission Flexible Plate Assembly

Part Number: 12654640$132.41 MSRP: $226.41You Save: $94.00 (42%)Chevrolet Camaro Engine Crankshaft Flywheel

Part Number: 24245480$256.15 MSRP: $620.26You Save: $364.11 (59%)Ships in 1-3 Business DaysChevrolet Camaro Flywheel Assembly

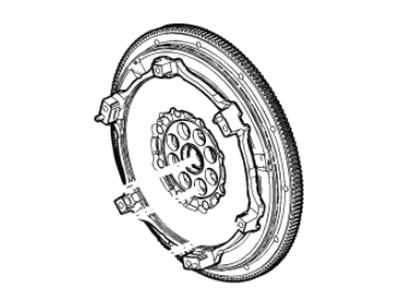

Part Number: 24264316$473.61 MSRP: $755.33You Save: $281.72 (38%)Chevrolet Camaro Plate Assembly, Automatic Transmission Flexible

Part Number: 12685003$59.81 MSRP: $103.17You Save: $43.36 (43%)Chevrolet Camaro Engine Crankshaft Flywheel

Part Number: 14088765$126.94 MSRP: $210.09You Save: $83.15 (40%)Ships in 1-2 Business DaysChevrolet Camaro Flywheel Assembly

Part Number: 14097667$90.83 MSRP: $183.15You Save: $92.32 (51%)Ships in 1-2 Business DaysChevrolet Camaro Engine Crankshaft Flywheel

Part Number: 12571611$348.48 MSRP: $555.78You Save: $207.30 (38%)Ships in 1-3 Business DaysChevrolet Camaro Flywheels & Flexplates

Part Number: 24287452$711.11 MSRP: $1215.94You Save: $504.83 (42%)Ships in 1-3 Business DaysChevrolet Camaro Plate Assembly, A/Trns Flex

Part Number: 12686890$60.80 MSRP: $100.66You Save: $39.86 (40%)Ships in 1-3 Business DaysChevrolet Camaro PLATE ASM-A/TRNS FLEX

Part Number: 12727438$60.71 MSRP: $103.81You Save: $43.10 (42%)Ships in 1-2 Business DaysChevrolet Camaro Engine Crankshaft Flywheel

Part Number: 471529$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business DaysChevrolet Camaro Automatic Transmission Flexible Plate Assembly

Part Number: 12699085$51.25 MSRP: $84.82You Save: $33.57 (40%)Ships in 1-3 Business DaysChevrolet Camaro Automatic Transmission Flexible Plate Assembly

Part Number: 12636325$45.61 MSRP: $110.40You Save: $64.79 (59%)Ships in 1-3 Business DaysChevrolet Camaro Flywheels & Flexplates

Part Number: 24267231$443.20 MSRP: $733.51You Save: $290.31 (40%)Chevrolet Camaro Automatic Transmission Flexible Plate Assembly

Part Number: 12652168$79.08 MSRP: $126.14You Save: $47.06 (38%)Ships in 1-3 Business DaysChevrolet Camaro Engine Crankshaft Flywheel

Part Number: 24240678$748.18 MSRP: $1192.74You Save: $444.56 (38%)Ships in 1-3 Business DaysChevrolet Camaro Flywheel Assembly

Part Number: 14100559$84.00 MSRP: $432.18You Save: $348.18 (81%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 27 Results

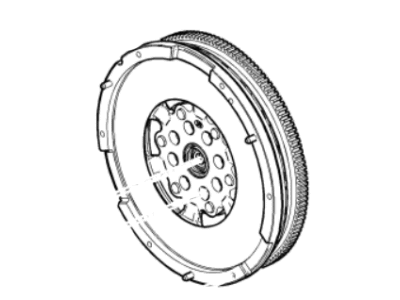

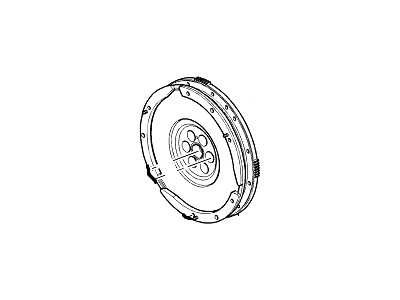

Chevrolet Camaro Flywheel

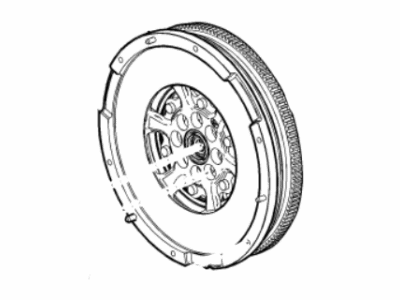

The Flywheel of Chevrolet Camaro vehicles accomplishes three essential operations by serving as an energy storage unit for power smoothing and as a starting element for crankshaft rotation and by maintaining clutch disc friction. The classification of Flywheel consists of two categories namely solid Flywheel and dual mass Flywheel (DMFs). A solid Flywheel maintains a basic design yet DMFs utilize two separate masses connected by a damping unit thus they effectively reduce engine vibrations and deliver improved performance and acoustic improvements. The clutch assembly requires new Flywheel eventually because contact surface deterioration leads to both scoring damage and the formation of warpage. Parts from DMFs systems are non-resurfaced thus replacement emerges as the necessary solution during maintenance. Starting up the vehicle causes grinding sounds when the ring gear of the system part suffers damage which may prove wear that needs replacement of either the Chevrolet replacement unit or ring gear. The Chevrolet Camaro replacement part performs essential functions by ensuring a smooth engine operation together with proper clutch operation within the Camaro.

Each OEM Chevrolet Camaro Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Flywheel Parts Questions & Experts Answers

- Q: How to Remove and Install the Flywheel in V6 engine on Chevrolet Camaro?A:To remove the transmission, check components such as oil seals and replace them if necessary. For manual transmission models, remove the clutch and check or replace the clutch components and release bearing. Make alignment marks on the flywheel and crankshaft to simplify replacement, as the bolt holes are slightly offset. Hold the flywheel/driveplate stationary while unscrewing the bolts; use a transmission mounting bolt and a wide-bladed screwdriver to prevent turning. Remove each bolt in an alternating pattern, ensuring new replacements are obtained for reassembly, as these bolts must be replaced whenever removed due to severe stresses. Carefully remove the retainer and flywheel, noting its weight. Clean the flywheel to remove grease and oil, inspecting for cracks, grooves, burned areas, and score marks, with light scoring removable using emery cloth. Check for cracked ring gear teeth and warpage using a straight-edge. Clean the mating surfaces of the flywheel and crankshaft, replacing the oil seal if leaking, especially in high-mileage engines. While the flywheel is off, clean its inboard face and the crankshaft speed/position sensor. When installing, align the flywheel/driveplate on the crankshaft using the marks made during removal, then install the retainer and new bolts, tightening them by hand. Lock the flywheel as done during disassembly, tightening the new bolts in a diagonal sequence to the specified torque in two or three stages. The remainder of the installation follows the reverse of the removal process.

Related Chevrolet Camaro Parts

Browse by Year

2024 Flywheel 2023 Flywheel 2022 Flywheel 2021 Flywheel 2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2010 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1996 Flywheel 1995 Flywheel 1994 Flywheel 1993 Flywheel 1992 Flywheel 1991 Flywheel 1990 Flywheel 1989 Flywheel 1988 Flywheel 1987 Flywheel 1986 Flywheel 1985 Flywheel 1984 Flywheel 1983 Flywheel 1982 Flywheel