My Garage

My Account

Cart

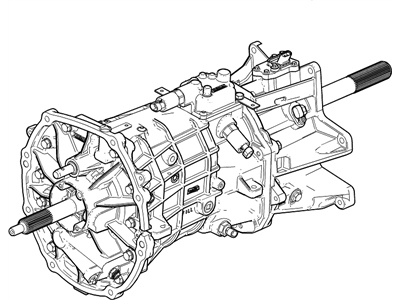

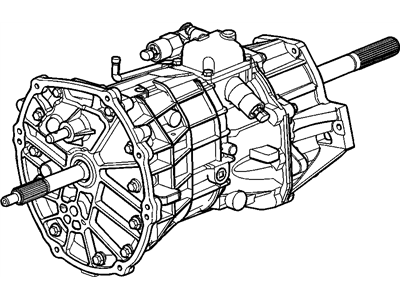

Genuine Chevrolet Corvette Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

64 Transmission Assemblies found

Chevrolet Corvette Manual Transmission Assembly

Part Number: 24272358$3873.48 MSRP: $4409.69You Save: $536.21 (13%)Ships in 1-2 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24290543$6987.95 MSRP: $7904.93You Save: $916.98 (12%)Ships in 1-3 Business DaysChevrolet Corvette Transmission Assembly, Man

Part Number: 24264053$3582.51 MSRP: $4052.62You Save: $470.11 (12%)Ships in 1-3 Business DaysChevrolet Corvette Transmission Asm, Auto (0Ydd) (Goodwrenc)

Part Number: 24216090$2371.94 MSRP: $2674.88You Save: $302.94 (12%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24255978$4256.02 MSRP: $4814.50You Save: $558.48 (12%)Ships in 1-3 Business DaysChevrolet Corvette TRANSMISSION ASM, AUTO 08CYA (SERV REMAN) *PROGRAMMING

Part Number: 19432237$4047.63 MSRP: $4531.25You Save: $483.62 (11%)Ships in 1-3 Business DaysChevrolet Corvette Automatic Transmission Assembly

Part Number: 19433321$6088.23 MSRP: $6815.88You Save: $727.65 (11%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24272362$4530.62 MSRP: $5125.13You Save: $594.51 (12%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24272361$7028.30 MSRP: $7950.57You Save: $922.27 (12%)Ships in 1-3 Business DaysChevrolet Corvette Automatic Transmission Assembly

Part Number: 19433286$4579.81 MSRP: $5109.51You Save: $529.70 (11%)Ships in 1-3 Business DaysChevrolet Corvette TRANSMISSION ASM, AUTO 11CYA (SERV REMAN) *PROGRAMMING

Part Number: 19432239$4280.09 MSRP: $4794.23You Save: $514.14 (11%)Ships in 1-3 Business DaysChevrolet Corvette Transmission Assembly, Man

Part Number: 24255982$4228.42 MSRP: $4783.28You Save: $554.86 (12%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24264055$7042.14 MSRP: $7966.23You Save: $924.09 (12%)Ships in 1-3 Business DaysChevrolet Corvette Automatic Transmission Assembly

Part Number: 19433287$4567.76 MSRP: $5095.89You Save: $528.13 (11%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24255980$4228.42 MSRP: $4783.28You Save: $554.86 (12%)Ships in 1-3 Business DaysChevrolet Corvette Manual Transmission Assembly

Part Number: 24290539$6746.47 MSRP: $7631.75You Save: $885.28 (12%)Ships in 1-3 Business DaysChevrolet Corvette Transmission Assembly, Man

Part Number: 24264054$6462.43 MSRP: $7310.44You Save: $848.01 (12%)Chevrolet Corvette Manual Transmission Assembly

Part Number: 24252997$7286.81 MSRP: $8243.00You Save: $956.19 (12%)Chevrolet Corvette Transmission Assembly, Man

Part Number: 24264046$3895.78 MSRP: $4407.00You Save: $511.22 (12%)

| Page 1 of 4 |Next >

1-20 of 64 Results

Chevrolet Corvette Transmission Assembly

Each OEM Chevrolet Corvette Transmission Assembly we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Corvette Transmission Assembly Parts Questions & Experts Answers

- Q: Is replacing a transmission assembly a challenging task for a do-it-yourselfer on Chevrolet Corvette?A:An overhaul of a manual transmission is quite complex as a DIY project; it involves dismantling and assembling not only a large number of small components but fine shimming of clearances, which may require the use of such items as select-fit spacers and snap-rings. If problems do develop with a manual transmission system, it is relatively easy for a competent do-it-yourselfer to pull the transmission and re-install it: the overhaul process is not typically one a home mechanic would undertake since time and costs associated with it are usually higher than a simple replacement, although used rebuilds are sometimes available through dealer parts departments and auto parts stores. Any naive and ill-prepared person, given the proper set of special tools, can rebuild a transmission if he or she does not miss a single step of the process. Tools necessary for the overhaul can be internal and external snap-ring pliers, bearing puller, slide hammer, set of pin punches, dial indicator and may be a hydraulic press as well as a large workbench and a vise or transmission stand. When disassembling a system, it is relevant to write down the sequence of part removal, where they were located, and how they were fixed. Knowledge of the area that is not functioning properly may aid in analysis and repair of transmission, since some of the problems can be associated with definite section of the transmission.

Related Chevrolet Corvette Parts

Browse by Year

2024 Transmission Assembly 2023 Transmission Assembly 2022 Transmission Assembly 2021 Transmission Assembly 2020 Transmission Assembly 2019 Transmission Assembly 2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly