My Garage

My Account

Cart

Genuine Chevrolet Malibu Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Oxygen Sensors found

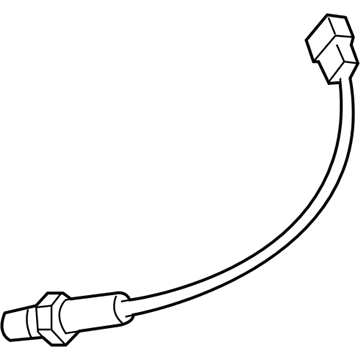

Chevrolet Malibu Heated Oxygen Sensor

Part Number: 12701634$61.56 MSRP: $125.58You Save: $64.02 (51%)Ships in 1-2 Business DaysChevrolet Malibu Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209808$72.08 MSRP: $147.04You Save: $74.96 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12606671$45.63 MSRP: $93.10You Save: $47.47 (51%)Ships in 1-3 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12616502$73.22 MSRP: $149.38You Save: $76.16 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor,Heated Oxygen

Part Number: 12559850$59.70 MSRP: $121.78You Save: $62.08 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor,Heated Oxygen(Position 2)

Part Number: 12578624$84.12 MSRP: $171.60You Save: $87.48 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Asm,Heated Oxygen (Position 2)

Part Number: 19209807$87.40 MSRP: $178.30You Save: $90.90 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor,Heated Oxygen(Position 1)

Part Number: 12594452$53.96 MSRP: $110.06You Save: $56.10 (51%)Ships in 1-3 Business DaysChevrolet Malibu Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12608662$60.80 MSRP: $124.02You Save: $63.22 (51%)Ships in 1-2 Business DaysChevrolet Malibu Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12608663$70.06 MSRP: $142.92You Save: $72.86 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Asm,Heated Oxygen

Part Number: 19178958$61.38 MSRP: $125.22You Save: $63.84 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor,Heated Oxygen(Position 2)

Part Number: 12618009$84.12 MSRP: $171.60You Save: $87.48 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12596701$41.83 MSRP: $131.10You Save: $89.27 (69%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Post, Catalyst Bank 1 Sensor 2)

Part Number: 12661898$63.28 MSRP: $127.99You Save: $64.71 (51%)Ships in 1-3 Business DaysChevrolet Malibu Sensor,Heated Oxygen(Position 2)

Part Number: 12597947$84.12 MSRP: $171.60You Save: $87.48 (51%)Ships in 1-2 Business DaysChevrolet Malibu Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12608712$70.55 MSRP: $143.93You Save: $73.38 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Post, Catalyst Bank 1)

Part Number: 12656543$87.15 MSRP: $176.24You Save: $89.09 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Position 1) *Black

Part Number: 12568234$55.21 MSRP: $112.62You Save: $57.41 (51%)Ships in 1-2 Business DaysChevrolet Malibu Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12590790$57.26 MSRP: $102.72You Save: $45.46 (45%)Chevrolet Malibu Sensor,Exhaust Oxygen

Part Number: 19211437$18.91 MSRP: $33.92You Save: $15.01 (45%)

| Page 1 of 2 |Next >

1-20 of 33 Results

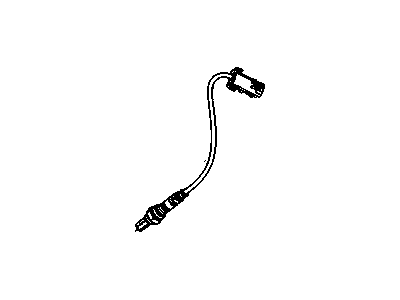

Chevrolet Malibu Oxygen Sensor

The Oxygen Sensor in Chevrolet Malibu economically important part which measures the concentration of unburned oxygen in the exhaust emissions refer to the engine control computer to adjust the air-fuel mixture effectively to reduce emission and enhance performance. The implementation of the sensor to produce a voltage signal proportional to the oxygen concentration allows the engine to be controlled in "closed loop" which remedies the efficiency of the catalytic converter. Chevrolet Malibu models most often use zirconium dioxide oxygen sensors and can utilize both, the narrow band and wide band types. The narrow-band sensors supply switched on and off rich/lean signals, and on the other hand, the wide-band sensors offer a bigger scope of air-fuel mixture ratios. These sensors degrade and fail progressively and this failure is worsened by contaminants and therefore cause higher emissions and less efficiency in fuel. Chevrolet Malibu vehicles shall be checked reported by the Oxygen Sensor to maintain optimal performance and check for other issues.

Each OEM Chevrolet Malibu Oxygen Sensor we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Oxygen Sensor Parts Questions & Experts Answers

- Q: What precautions should be taken when working with an oxygen sensor on Chevrolet Malibu?A:Some words of warning, when servicing an oxygen sensor, one must be careful, as it is located in the exhaust manifold or pipe, and when cold, the metal contracts, and becomes incredibly tight; a five-minute warm up assists in protecting the sensor or the threads to which the sensor is attached from becoming damaged, but be careful not to burn yourself in the process. All models have two oxygen sensors: both upstream and downstream. In 1.5L engines, the upstream is located at turbocharger outlet elbow, the downstream is located beside the Catalytic Converter. For 2.0L engines the upstream sensor is situated at the turbo outlet just ahead of the catalytic converter, while the downstream sensor is found in the exhaust pipe right after it. In 2.5L engines the upstream sensor is placed in the exhaust manifold, and the downstream sensor is located under the catalytic converter. When the oxygen sensor has to be serviced, it is important not to damage the pigtail which is permanently connected to it as well as the electrical connection; it is also important not to expose the connector and the sensor end to contaminants, it is also prohibited to use solvents when cleaning the sensor; the handling of the sensor must always be gentle and care should be taken to ensure the silicone boot is positioned correctly so that it will not melt or cause The upstream oxygen sensor has to be taken off by first, taking off the engine cover, disconnecting its electrical connector and then unclipping it before it is pulled off. In the case that one can reinstall the old sensor, one must use anti-seize compound on threads; for the new sensor this is not required since they coat it themselves. Installation is done in a reverse manner with caution that the screws of the sensor are tightened to the recommended torque. To get to the downstream oxygen sensor, lift the vehicle safe, and as you get to the connector beside the heat shield and ducting for 1.5L turbo, unplug the connector, unscrew the sensor with the vehicle off, and if you are using the old sensor, use the anti-seize compound. As with removal, installation is the exact opposite and the sensor is torqued to the correct level.

Related Chevrolet Malibu Parts

Browse by Year

2024 Oxygen Sensor 2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor 2002 Oxygen Sensor 2001 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor 1998 Oxygen Sensor 1997 Oxygen Sensor 1983 Oxygen Sensor 1982 Oxygen Sensor