My Garage

My Account

Cart

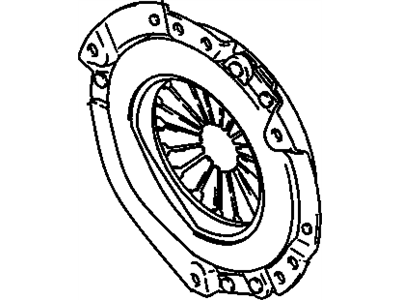

Genuine Chevrolet Metro Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Pressure Plates found

Chevrolet Metro Cover, Clutch Pressure Plate

Part Number: 96062093$85.04 MSRP: $171.49You Save: $86.45 (51%)

Chevrolet Metro Pressure Plate

Each OEM Chevrolet Metro Pressure Plate we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Metro Pressure Plate Parts Questions & Experts Answers

- Q: How to Check and Replace Clutch Disc and Pressure Plate on Chevrolet Metro?A:To induce servicing to the clutch parts, one has to pull out the transaxle, although the engine remains fitting in the car. In this case, if the engine is to be pulled out for a big overhaul, it is good to inspect the clutch and replace if parts that have worn out. In view of the fact that clutch parts are relatively cheap compared to the amount of work that is required to get at them, it is advisable to replace them whenever an engine or transaxle is removed, unless they are new or very lightly worn. First of all, unbolt the transaxle and lift the engine, which can be done with an engine stand, or with a normal jack with a block of wood under the oil pan. They can also stay united as parts to the transaxle housing in a release fork, shaft as well as bearing. In order to support the clutch disc successfully during removal a clutch alignment tool should be inserted through the clutch disc hub. Check for indexing marks on the flywheel and pressure plate and if there are none, then make up your own when it is time to fit them back. Tighten the bolts on the pressure plate to the flywheel in a star like fashion, then remove the bolts, the pressure plate and the clutch disc. In inspection, take the time to ensure that the flywheel has no cracks and other imperfections; the flywheel can also be sent for grinding to be made flat and very smooth. Check the thickness of the clutch disc lining; there should be at least 1/16 inch of lining above the heads of the rivets, and there should be no damage. It is recommended that the Release Bearing should be replace together with the clutch disc. Check the pressure plate for damages, or if it seems to be running hot; this is another component that ought to be changed. Before the installation process, ensure that you clean the flywheel and the pressure plate so that they are free from any oils or the greases. Align the clutch disc and pressure plate with the flywheel and engage the pressure plate hooks to the flywheel grooves; tighten the pressure plate bolts to flywheel just enough to hold the plates together. Align the clutch disc with the help of an alignment tool and-as with the pressure plate-tighten the bolts in a criss-cross fashion to minimize distortion; withdraw the tool. High-temperature grease must be applied to the inner groove of the release bearing, and also to the release lever and the retainer of the transaxle input shaft before fitting the release bearing. Last of all, fit back the transaxle and all components that had been removed, washers included preferably with tightened torque.