My Garage

My Account

Cart

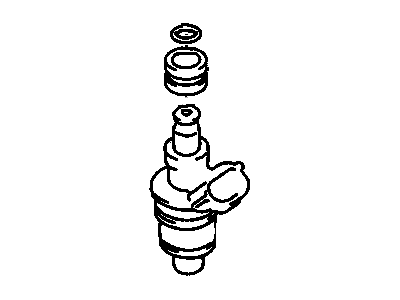

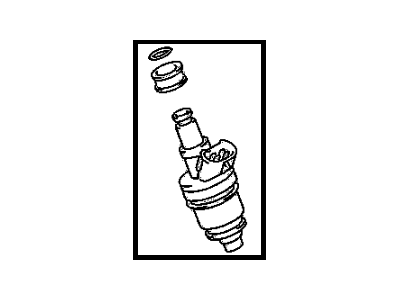

Genuine Chevrolet Tracker Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Fuel Injectors found

Chevrolet Tracker Multiport Fuel Injector Kit

Part Number: 91176152$259.21 MSRP: $467.03You Save: $207.82 (45%)

Chevrolet Tracker Fuel Injector

In Chevrolet Tracker automobiles, the Fuel Injector plays the important role of supplying the required quantity of fuel in the engine cylinders. It is under the control of ECM, which send a signal to the injectors to spray fuel depending with the load of its engine in order to achieve the most desirable air to fuel mixture. Chevrolet Tracker vehicles have employed diverse Fuel Injectors mainly embracing direct and indirect Injection techniques. Direct injection injects fuel in the combustion chamber while on the other hand, indirect injection mingles fuel and air outside the combustion chamber. These systems improve the performance and economic efficiency by accurately regulating the supply of fuel which can be observed as a step forward from the carburetor systems. Failed fuel injectors affects the performance of the engine, thus making it important to replace Chevrolet Tracker's fuel injectors as soon as they develop issues.

Each OEM Chevrolet Tracker Fuel Injector we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Tracker Fuel Injector Parts Questions & Experts Answers

- Q: How to check and replace the fuel injector and fuel pressure regulator on Chevrolet Tracker?A:To test the fuel injector, unfasten the air intake case from the Throttle Body and relocate it aside, then turn on the car engine and examine the pattern of the injector using a timing light; it should give a thick-cone spray. After turning off the engine ensure that the injector is not dripping, if it is dripping, replace it with one that drips not more than one droplet per minute. Remove the electrical connector from the injector and using a digital ohmmeter measure the resistance across the injector coils; if the values are out of range then replace the injector. To start the replacement begin by releasing fuel system pressure and then removing the negative terminal of the battery. Take off the fuel feed line from the throttle body, unlock the injector cap and disconnect the injector connector. Carefully blow the injector off the throttle body using air with the caution not to exceed 85 psi. The fuel filters should be cleaned if they are dirty; do so. Before fitting the new injector gently grease the O-rings with light oil and arrange them in correct position to the wiring harness. Put the injector cover back and reconnect the negative terminal of the battery and then pressurize the fuel system for leakage test fittings. The following procedure should be taken for the fuel pressure regulator; The negative terminal of the battery should be loosened, and then the pressure in the fuel system should be released, and then the fuel return hose and also the vacuum hose should be disconnected. Take out the screws and place the new regulator fitted with the O-ring that had been lubricated, place the screws back again and connect back the hoses. Connect the battery as usual and with the help of Cinus air pressurize the fuel system and look for leaks. To check the throttle opener, first release the vacuum and remove the hose, apply vacuum and it should retract the plunger if it fails replace it. For replacement, remove throttle opener and bracket, then fit the new one and adjust the throttle opener by checking rpms of the engine by using a tachometer and adjust it accordingly. ; the air valve is intended to provide additional air needed to pass the throttle plate when cold; test if it opens when the engine is cold and vice-versa for the warm engine. If it doesn't function as supposed then replace the faulty part and employ a fresh gasket when reseating the cap.

Related Chevrolet Tracker Parts

Browse by Year

2004 Fuel Injector 2003 Fuel Injector 2002 Fuel Injector 2001 Fuel Injector 2000 Fuel Injector 1999 Fuel Injector 1998 Fuel Injector 1997 Fuel Injector 1996 Fuel Injector 1995 Fuel Injector 1994 Fuel Injector 1993 Fuel Injector 1992 Fuel Injector 1991 Fuel Injector 1990 Fuel Injector 1989 Fuel Injector