My Garage

My Account

Cart

Genuine Chevrolet Trailblazer Brake Pad

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Brake Pads found

Chevrolet Trailblazer Front Disc Brake Pad Kit

Part Number: 19178358$110.99 MSRP: $218.26You Save: $107.27 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Pad Kit,Rear Disc Brake

Part Number: 89027184$80.27 MSRP: $151.46You Save: $71.19 (47%)Ships in 1-2 Business DaysChevrolet Trailblazer Pad Kit,Front Disc Brake

Part Number: 88964424$77.97 MSRP: $147.14You Save: $69.17 (48%)Ships in 1-2 Business DaysChevrolet Trailblazer Rear Disc Brake Pad Kit

Part Number: 42782666$136.45 MSRP: $265.98You Save: $129.53 (49%)Chevrolet Trailblazer Front Disc Brake Pad Kit

Part Number: 42788125$92.25 MSRP: $254.69You Save: $162.44 (64%)Ships in 1-2 Business DaysChevrolet Trailblazer PAD ASM,FRT DISC BRK

Part Number: 19332544$71.92 MSRP: $130.77You Save: $58.85 (45%)Ships in 1-2 Business DaysChevrolet Trailblazer Rear Disc Brake Pad Kit

Part Number: 19332543$72.73 MSRP: $137.22You Save: $64.49 (47%)Ships in 1-2 Business DaysChevrolet Trailblazer Front Disc Brake Pad Kit

Part Number: 19332216$126.13 MSRP: $224.22You Save: $98.09 (44%)Ships in 1-2 Business DaysChevrolet Trailblazer Front Disc Brake Pad Kit

Part Number: 42881020$135.91 MSRP: $254.69You Save: $118.78 (47%)Chevrolet Trailblazer Pad Kit,Front Disc Brake

Part Number: 88964423$87.76 MSRP: $157.44You Save: $69.68 (45%)

Chevrolet Trailblazer Brake Pad

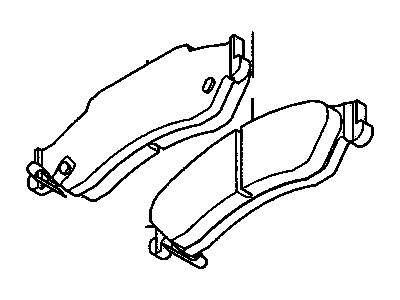

Chevrolet Trailblazer cars employ Brake Pad as part of the brake system to prevent the car through friction on Brake Rotor. These Brake Pad consist of friction materials that are coated on metal plates to be in a position to withstand high temperature regimes during the usage. This it is important to note that Brake Pad like other components deteriorate with use and need replacement, which is normally after fifty thousand miles, a notification of wear indicator being worn out is usually provided. Chevrolet Trailblazer Brake Pad have been available in many types that include the Non-metallic, the Semi-metallic, the fully metallic and the Ceramic brake pad type. They all have their unique properties regarding the coefficients of friction, wear and acoustic levels. When it comes to Brake Pad selection and installation of Brake Pad including hardware guarantees the premier performance and durability of Brake Pad without brake fade and uneven wear.

Each OEM Chevrolet Trailblazer Brake Pad we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Trailblazer Brake Pad Parts Questions & Experts Answers

- Q: How to replace front and rear brake pads on Chevrolet Trailblazer?A:This procedure applies to the front and rear brake pads section as seen in the figure below, The first step is to take off the brake fluid cap, and then sucking out nearly two-thirds of the fluid, and then putting the cap back on. Lose the bolts on the front or rear wheels, lift the car, and secure it on the jack stands placing blocks under the wheels on the opposite end. Take off the wheels and operate on one brake at a time for easier working and use the assembled brake for comparison. Examine the Brake Disc, and if machining has to be done, then refer to the following instructions when removing the disc. Before taking apart the brake, clean it by removing the brake dust with a brake system cleaner, and allow the brake to dry with a drain pan beneath to catch the residue, do not blow off the brake dust with compressed air. Before pulling off the caliper and the pad, one must use C-clamp to force the piston or several pistons into the caliper so as to create space for a new pad as one monitors the level of the brake fluid in master cylinder lest it spill over. On front brake pads, unbolt the smallest mounting bolt and then swivel the caliper up and provide a little support to it. For rear pads, hold the caliper up with the spline, remove the upper mounting bolt with one wrench and swing the caliper down for the access to the brake pads. Both inner and outer brake pads, and upper and lower pad retainers to the caliper mounting bracket should be removed, and if cracked or distorted, replaced. In the back side of both pads paint the anti squeal compound and let it settle for a few minutes before installing them. Finally, the upper and lower pad retainers must to be installed back on the caliper mounting bracket and then the inner and outer brake pads also. In case of front pads, for the caliper mounting bolt, check for signs of scoring and corrosion, and relube it with high temperature brake grease, if the bolt is dry then do the same with the upper mounting bolt. When inspecting rear pads, note and assess the slide pin and rubber boot; if the pin is dry, apply a thin coat of high temperature brake grease; for the lower pin, the same response. Finally when reinstalling the caliper the mounting bolts should be tightened to the specified torque setting as is the wheel lug nuts. After the completion of the job, apply pressure on the brake pedal to make the pad to stick on the disc several times, inspect the brake fluid level if low then add it and inspect he operation of the brake before use of the car.