My Garage

My Account

Cart

Genuine Chevrolet Trailblazer Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Engine Mounts found

Chevrolet Trailblazer Engine Mount

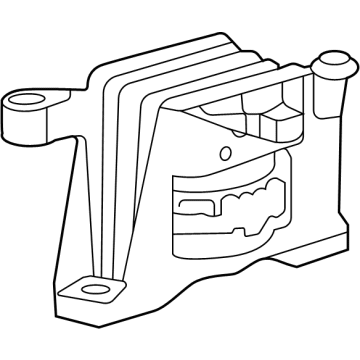

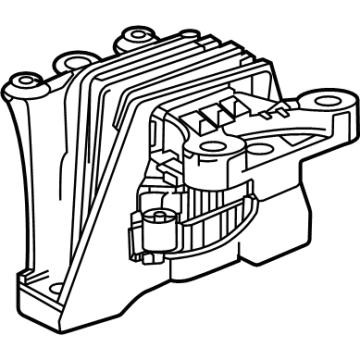

Part Number: 15062381$75.07 MSRP: $129.48You Save: $54.41 (43%)Ships in 1-2 Business DaysChevrolet Trailblazer Mount,Engine (Less Brackets)

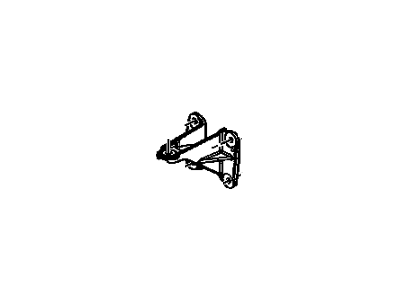

Part Number: 19244832$156.11 MSRP: $249.54You Save: $93.43 (38%)Ships in 1-2 Business DaysChevrolet Trailblazer Bracket,Engine Mount LH

Part Number: 88964337$83.88 MSRP: $149.38You Save: $65.50 (44%)Ships in 1-2 Business DaysChevrolet Trailblazer Bracket, Eng Mt Eng Si

Part Number: 60002825$64.39 MSRP: $101.32You Save: $36.93 (37%)Ships in 1-3 Business DaysChevrolet Trailblazer Bracket,Engine Mount RH

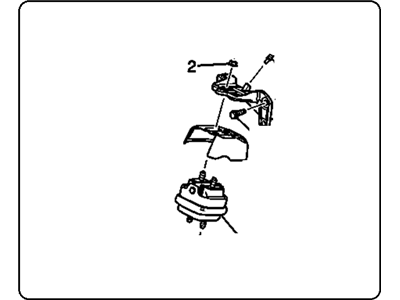

Part Number: 88964338$91.60 MSRP: $144.12You Save: $52.52 (37%)Ships in 1-3 Business DaysChevrolet Trailblazer Brace, Eng Mt

Part Number: 55512875$20.74 MSRP: $34.33You Save: $13.59 (40%)Ships in 1-3 Business DaysChevrolet Trailblazer MOUNT-ENG

Part Number: 60006090$84.22 MSRP: $134.31You Save: $50.09 (38%)Ships in 1-2 Business DaysChevrolet Trailblazer Brace, Eng Mt

Part Number: 42481285$5.91 MSRP: $9.31You Save: $3.40 (37%)Ships in 1-3 Business DaysChevrolet Trailblazer Bracket, Eng Mt Eng Si

Part Number: 60002266$62.92 MSRP: $99.01You Save: $36.09 (37%)Ships in 1-3 Business DaysChevrolet Trailblazer MOUNT-ENG

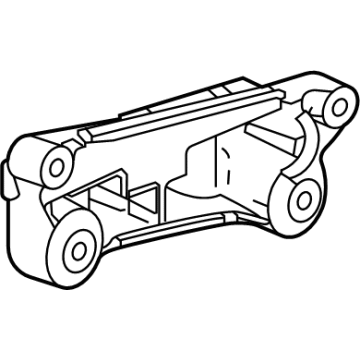

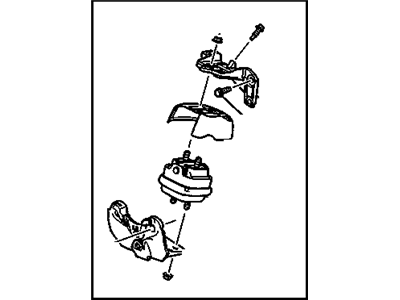

Part Number: 60005993$82.35 MSRP: $136.30You Save: $53.95 (40%)Ships in 1-2 Business DaysChevrolet Trailblazer Engine Mount Bracket Assembly

Part Number: 15062379$100.13 MSRP: $157.55You Save: $57.42 (37%)Chevrolet Trailblazer Bracket,Engine Mount (LH)

Part Number: 19258808$84.61 MSRP: $133.13You Save: $48.52 (37%)

Chevrolet Trailblazer Engine Mount

A Chevrolet Trailblazer Engine Mount executes two core responsibilities because it both decreases engine-operated vibrations and noise and maintains engine position and stability in the chassis structure. Driving comfort and safety operation require this function to be operational. The original design of Engine Mount incorporates metal pieces wrapped in rubber insulators and different models use hydraulic elements to absorb vibrations better. Electronic active mounts present the updated development by changing their stiffness according to engine speed for maximum performance results. Trailblazer vehicles adopted three types of Engine Mount starting from standard rubber mounts through hydraulic mounts and eventually ending with active mounts. The different types of Chevrolet Engine Mount present varying capacities for vibration absorption and engine movement control but active mounts achieve the superior standard of performance. Chevrolet Trailblazer Engine Mount face deterioration because of heat exposure and aging which result in noise creation and vibration problems so scheduled inspections with appropriate maintenance steps become necessary.

Each OEM Chevrolet Trailblazer Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Trailblazer Engine Mount Parts Questions & Experts Answers

- Q: What should be done if engine mounts are broken or deteriorated in V8 engine on Chevrolet Trailblazer?A:Engine mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent damage to driveline components. During the check, the engine must be raised slightly to remove the weight from the mounts. To do this, raise the vehicle and support it securely on jackstands, then position a jack under the engine oil pan with a large block of wood between the jack head and the oil pan, carefully raising the engine just enough to relieve the weight from the mounts without using the jack to support the entire weight of the engine. Inspect the mounts for any cracks, hardened rubber, or separation from the metal plates, as rubber can sometimes split down the center. Applying rubber preservative or W0-40 can help slow deterioration. Check for any relative movement between the mount plates and the engine or frame using a large screwdriver or prybar; if movement is noted, check the tightness of the mount fasteners before condemning the mounts, as broken mounts typically allow the engine to move easily when pried or under load. To replace the mounts, disconnect the cable from the negative terminal of the battery, then raise the vehicle and support it securely on jackstands. In the engine compartment, remove the engine mount-to-frame bracket bolts, which consist of three bolts on each side securing the mounts to the frame bracket. Attach an engine hoist to the top of the engine for lifting, avoiding the use of a jack under the oil pan to prevent damage to the oil pump pick-up. If a hoist is unavailable, casting lugs on each side of the engine block can be used to support the engine's weight during mount replacement. Raise the engine slightly until the engine mount can be unbolted from the block, then remove it from the vehicle. Installation is the reverse of removal, using non-hardening thread-locking compound on the mount bolts and ensuring they are tightened to the specified torque.