My Garage

My Account

Cart

Genuine GMC Canyon Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Engine Mounts found

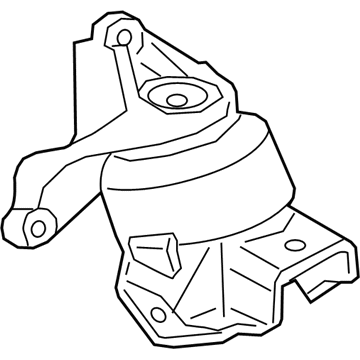

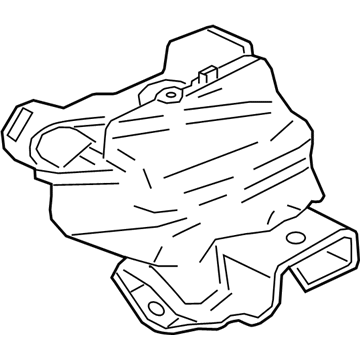

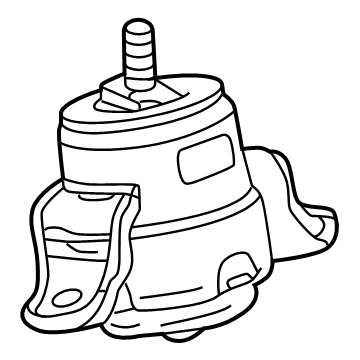

GMC Canyon Engine Mount Assembly

Part Number: 23195922$124.04 MSRP: $212.11You Save: $88.07 (42%)Ships in 1-2 Business DaysGMC Canyon Engine Mount Assembly

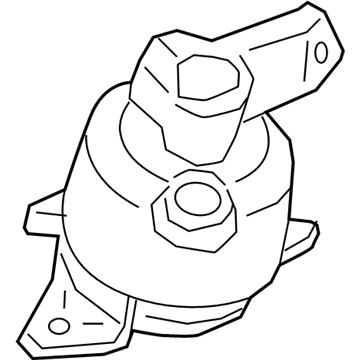

Part Number: 23436325$94.54 MSRP: $163.07You Save: $68.53 (43%)Ships in 1-3 Business DaysGMC Canyon Engine Mount Assembly

Part Number: 23436324$94.54 MSRP: $163.07You Save: $68.53 (43%)Ships in 1-3 Business DaysGMC Canyon Engine Mount

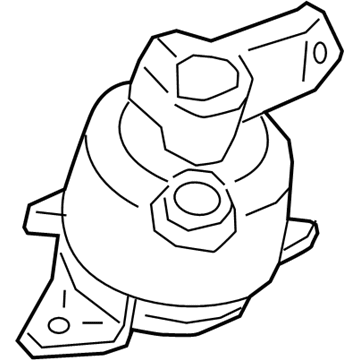

Part Number: 15925796$66.27 MSRP: $113.32You Save: $47.05 (42%)Ships in 1-2 Business DaysGMC Canyon Engine Mount

Part Number: 97287678$71.66 MSRP: $122.55You Save: $50.89 (42%)Ships in 1-2 Business DaysGMC Canyon Engine Mount Assembly

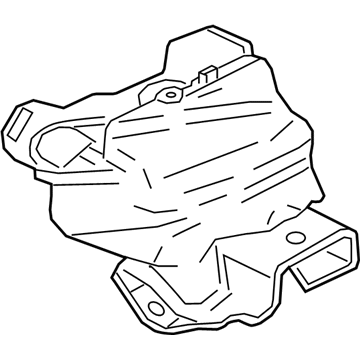

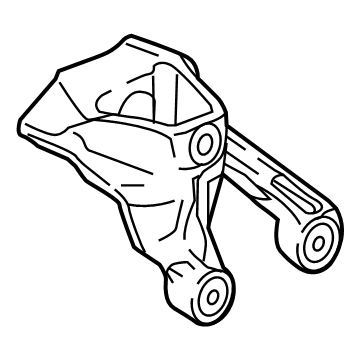

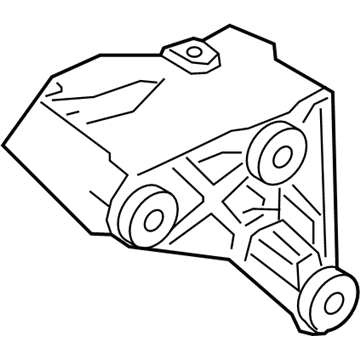

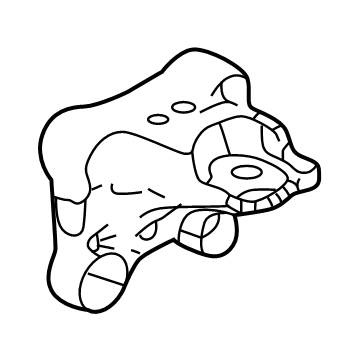

Part Number: 23405712$89.00 MSRP: $147.29You Save: $58.29 (40%)Ships in 1-3 Business DaysGMC Canyon Bracket, Engine Mount Engine Side

Part Number: 84060315$67.83 MSRP: $112.26You Save: $44.43 (40%)GMC Canyon Engine Mount Assembly

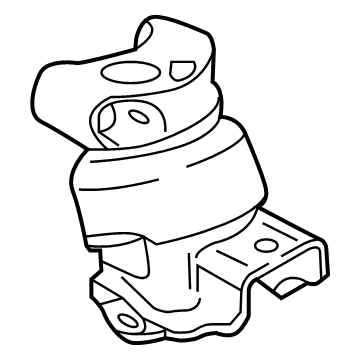

Part Number: 23226127$116.70 MSRP: $199.55You Save: $82.85 (42%)Ships in 1-2 Business DaysGMC Canyon Engine Mount Assembly

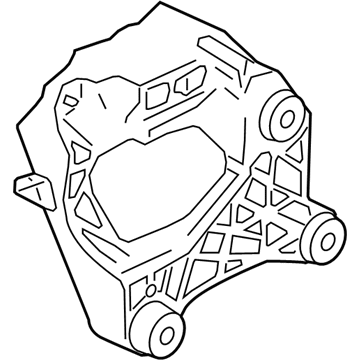

Part Number: 23195921$117.14 MSRP: $200.30You Save: $83.16 (42%)Ships in 1-2 Business DaysGMC Canyon Bracket, Engine Mount Engine Side

Part Number: 23373843$71.54 MSRP: $112.56You Save: $41.02 (37%)Ships in 1-3 Business DaysGMC Canyon Transmission Mount

Part Number: 15138532$42.35 MSRP: $71.79You Save: $29.44 (42%)Ships in 1-2 Business DaysGMC Canyon BRACKET-ENG MT ENG SI

Part Number: 84653919$52.76 MSRP: $83.02You Save: $30.26 (37%)Ships in 1-2 Business DaysGMC Canyon BRACKET-ENG MT ENG SI

Part Number: 85576429$52.76 MSRP: $83.02You Save: $30.26 (37%)Ships in 1-2 Business DaysGMC Canyon Engine Mount Assembly

Part Number: 84142207$84.65 MSRP: $140.10You Save: $55.45 (40%)Ships in 1-3 Business DaysGMC Canyon Bracket, Engine Mount Engine Side

Part Number: 23195925$61.08 MSRP: $96.10You Save: $35.02 (37%)

| Page 1 of 2 |Next >

1-20 of 22 Results

GMC Canyon Engine Mount

Each OEM GMC Canyon Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Canyon Engine Mount Parts Questions & Experts Answers

- Q: How to check and replace Engine Mount in inline engine on GMC Canyon?A:Engine mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent damage to driveline components. To check the mounts, the engine must be raised slightly to remove the weight from them. Begin by raising the vehicle and securely supporting it on jackstands, then position a jack under the engine Oil Pan with a large block of wood between the jack head and the oil pan, raising the engine just enough to relieve the weight on the mounts without fully supporting the engine. Inspect the mounts for any cracks, hardened rubber, or separation from the metal plates, noting that rubber may split down the center. Applying rubber preservative or WD-40 can help slow deterioration. Check for any relative movement between the mount plates and the engine or frame using a large screwdriver or pry bar; if movement is detected, verify the tightness of the mount fasteners before deciding to replace the mounts, as broken mounts typically allow noticeable engine movement when pried or under load. To replace the mounts, disconnect the cable from the negative battery terminal, raise the vehicle and support it securely on jackstands, and remove both front wheels. Place a block of wood on a floor jack and position it under the oil pan. If replacing the left-side engine mount, remove the intermediate steering shaft, then raise the engine enough to relieve the weight on the mounts. Remove the engine mount through-bolt, then continue raising the engine until the mount is clear of the frame bracket and remove the mount-to-block bolts. Twist the mount until it comes free, and for installation, reverse the removal process, using non-hardening thread-locking compound on the mount fasteners and ensuring they are tightened to the specified torque.

Related GMC Canyon Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount