My Garage

My Account

Cart

Genuine Oldsmobile Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

55 Brake Boosters found

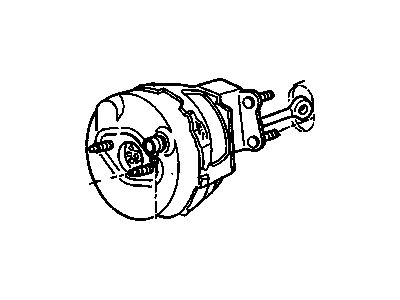

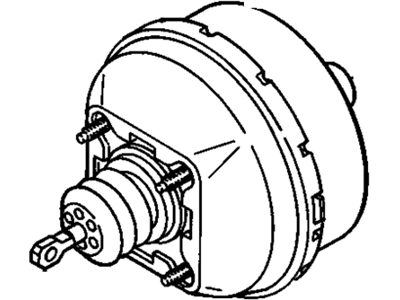

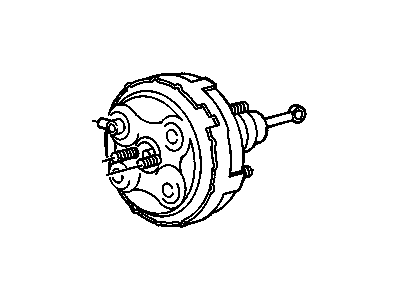

Oldsmobile Power Brake Vacuum Booster

Part Number: 18017407$214.39 MSRP: $443.36You Save: $228.97 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Booster Assembly, Power Brake ; Booster, Hydraulic Power Brake Booster; Brake Booster

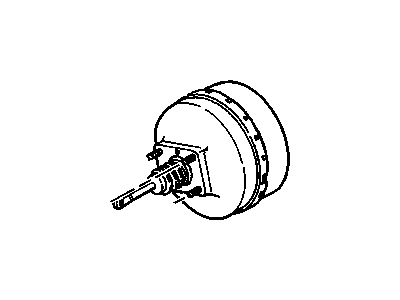

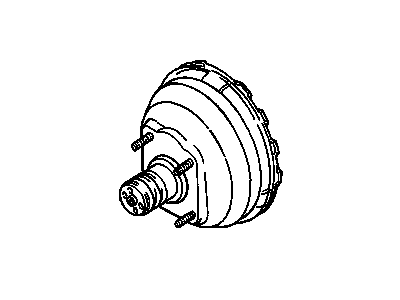

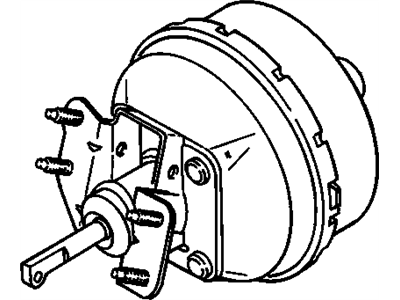

Oldsmobile Power Brake Booster

Part Number: 18045787$322.36 MSRP: $608.23You Save: $285.87 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster,Power Brake; Booster Assembly, Brake Booster

- Replaces: 18029880

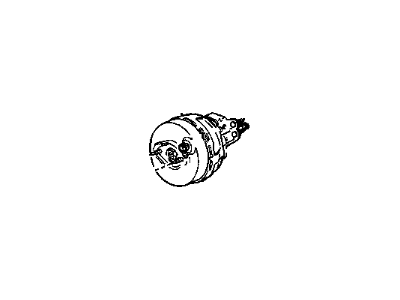

Oldsmobile Power Brake Booster Assembly

Part Number: 18029989$51.78 MSRP: $485.38You Save: $433.60 (90%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Asm,Power Brake ; Booster, Hydraulic Power Brake Booster; Brake Booster

- Product Specifications

- Other Name: Booster Assembly,Power Brake ; Booster, V; Brake Booster

- Product Specifications

- Other Name: Booster Asm,Power Brake ; Booster, Hydraulic Power Brake Booster; Brake Booster

- Product Specifications

- Other Name: Booster,Power Brake; Brake Booster

- Product Specifications

- Other Name: Brake Booster

- Product Specifications

- Other Name: Booster Asm,Power Brake (Remanufacture); Brake Booster

- Product Specifications

- Other Name: Booster Asm,Power Brake

- Replaces: 18015941

- Product Specifications

- Other Name: Booster,Power Brake; Booster, Booster Assembly, Brake Booster

- Replaces: 18044444, 18047694

- Product Specifications

- Other Name: Booster Asm,Power Brake; Brake Booster

- Replaces: 18015980

- Product Specifications

- Other Name: Booster Assembly, Power Brake

- Product Specifications

- Other Name: Booster Assembly, Power Brake; Brake Booster, Power Actuator

- Product Specifications

- Other Name: Booster,Power Brake; Brake Booster, Power Actuator

- Product Specifications

- Other Name: Booster Asm,Power Brake; Booster Assembly, Brake Booster

- Product Specifications

- Other Name: Booster Assembly, Power Brake ; Booster, Hydraulic Power Brake Booster; Brake Booster, Power Booster

- Replaces: 18045121, 18041444

- Product Specifications

- Other Name: Booster Kit,Power Brake (Vacuum) ; Booster, Hydraulic Power Brake Booster; Brake Booster

- Replaces: 18016409

- Product Specifications

- Other Name: Booster Asm,Power Brake ; Booster, Hydraulic Power Brake Booster; Booster Assembly, Brake Booster, Power Booster

- Replaces: 18043163, 18043638

- Product Specifications

- Other Name: Booster Assembly, Power Brake ; Booster, Hydraulic Power Brake Booster; Brake Booster

| Page 1 of 3 |Next >

1-20 of 55 Results

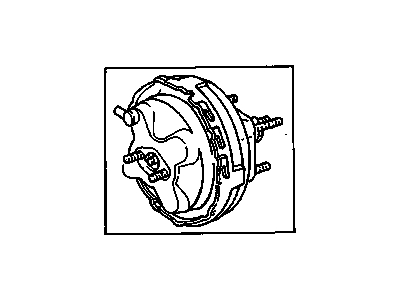

Oldsmobile Brake Booster

Looking to acquire brand new parts? Consider exploring our extensive inventory of genuine Oldsmobile Brake Boosters. Our offering of OEM Oldsmobile Brake Boosters not only comes with competitive prices but also includes a manufacturer's warranty. For added convenience, we provide a hassle-free return policy and rapid delivery service. Shop with confidence on our platform.

Oldsmobile Brake Booster Parts Questions & Experts Answers

- Q: What is the function and operation of a power brake booster on Oldsmobile Cutlass?A:A power brake booster has been incorporated in all models since its release with vacuum sourced from the engine manifold. There is sufficient vacuum stored to help out in two or three emergency stop applications of the brakes after which higher pedal pressures will be required by the Hydraulic brake system for a faulty booster. Delco-Moraine and Bendix power brake boosters work in almost the same way but may be of different designs. When brakes are released with the engine 'On', the vacuum is created on both sides of the power piston; the supply of atmospheric air is through a filter and stopped at the air valve. When the brake is applied the pedal presses the push rod to change the position of the air valve so that fresh air can enter and push the power piston to work the hydraulic master cylinder. The hydraulic reaction plate then relays information to the pedal so the driver can determine the intensity of the brake beings used. The power piston thus only moves until the braking force required is obtained and then stays at that position until there are changes in pressure from the pedal. When the pedal pressure is released the air valve returns to a position with the power piston, closes atmospheric air from the hydraulic brake system and the piston comes back to its initial position and reduces hydraulic pressure in the brake system. In the event when the vacuum supply fails such as during engine-off condition, the brake pedal can be depressed and it requires much higher brake pedal pressure similar to that of the standard anti lock braking system. The power brake unit has no regular maintenance that has to be done other than ocular inspection of the brake hoses and replacement of the filter. Removing the unit requires certain tools and it is more reasonable to fit in a new or ex-factory model than repair the initial booster if a problem arises.

Related Oldsmobile Parts

Browse by Model

88 Brake Booster 98 Brake Booster Achieva Brake Booster Alero Brake Booster Aurora Brake Booster Bravada Brake Booster Calais Brake Booster Custom Cruiser Brake Booster Cutlass Brake Booster Delta 88 Brake Booster Firenza Brake Booster Intrigue Brake Booster Omega Brake Booster Silhouette Brake Booster Toronado Brake Booster