My Garage

My Account

Cart

Genuine Pontiac G6 Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Boosters found

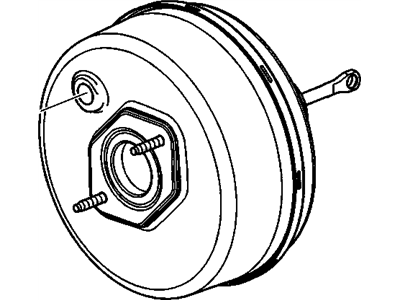

Pontiac G6 Hydraulic Power Brake Booster

Part Number: 25878055$135.92 MSRP: $256.46You Save: $120.54 (47%)Ships in 1-2 Business Days

Pontiac G6 Brake Booster

The brake booster in Pontiac G6 car models must be restorative as it assists in increasing the power of brakes by the usage of force that avails more convenience to the driver. Especially, the vacuum-operated brake system works mainly through using a vacuum device that increases the force applied on the brake pedal and transmits the enhanced force to the master cylinder. This system as in the case of other vacuum based systems enabled smoother and efficient braking especially when the engine is in operation which provided the vacuum. The Brake Boosters that may be used in the various ptomac G6 models include the vacuum operated and hydraulic Boosters. Vacuum boosters are usually dependable but often get choked up and hydraulic boosters make use of fluid pressure for boost. Single or dual diaphragm boosters can vary and the size of the diameter of boosters can vary with the amount of power assistance.

Each OEM Pontiac G6 Brake Booster we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac G6 Brake Booster Parts Questions & Experts Answers

- Q: How to Inspect and Check the Brakes and Brake Booster for Issues on Pontiac G6?A:Brakes should be checked either when the wheels have been taken off or if there are signs that something could be wrong; these are whereby the vehicle pulls to the side on application of brakes, squealing or dragging noises, excessive travel of the pedals and pulsating or soft pedals, or if there are signs of brake fluid leakage. Disc brakes can be checked visually by simply removing station hub caps, loosening the wheel lug nuts while the car is on the ground but securely lifted using a jack and two jackstands-then by removing the wheels to get access to the disc brake caliper & pads. The thickness of outer and inner pads must be measured and compared with the indicated values; if, for example, one of the values is less, all the pads must be replaced. There should be inspection of the disc for score marks, wear and burned spots and if there is an indication of a problem, then servoing or replacement is needed. Before the wheels can be reinstalled all the brake lines and hoses should be checked for signs of damages of wear. When wheels have been fixed and the car dropped to the ground, the lug nuts should be tightened to the right level of torque. For the brake booster check, the brake should be fully depressed with the key set in the starting position and seated in the driver's seat: the pedal should move slightly when the engine is started. While the engine is running the brake pedal must not alter in distance travelled after several depressions. Again, after switching off the engine, pressing the pedal for about 30 seconds should give no movement. The decrease in pedal travel should occur after the engine is restarted, and the brake is firmly depressed several times; otherwise the failure lies with the brake booster.