My Garage

My Account

Cart

Genuine Pontiac Phoenix Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Rack And Pinion found

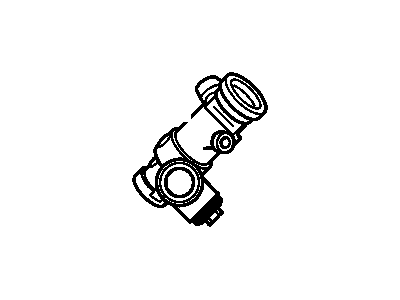

Pontiac Phoenix Rack And Pinion

Pontiac Phoenix Rack And Pinion is an intermediate that through its action it converts rotational force exerted by the wheel into lateral force of the front wheels. This is arrangement is made through rack and pinion system in which the pinion gear is located on the steering column shaft while the rack gear is accommodated in a metallic tube which is bolted on the chassis. The majority of contemporary cars comprising Pontiac Phoenix models apply power assisted for rack & pinion steering in which fluid pressure facilitates the lateral motion of the rack inside the tube. Lubrication System Pontiac Phoenix Vehicles have hydraulic power rack and pinion systems which have the following problems: Leaking of O-ring seals due to their deterioration and Power steering hoses that are worn. Some of the common signs that you are likely to experience if your vehicle's steering rack has developed issues include stiff and unresponsive steering, grinding or abrasive like sound, the car pulls to the side and wanders. If the steering wheel gets loose or if the car hardly responds to the steering wheel commands, then the rack and pinion should be replaced. There are some problems associated with the rack and pinion system, yet its importance and application to the flow of vehicles cannot be overestimated, it serves as the main type of the steering mechanism with clear directions and accurate feedback for the driver.

Each OEM Pontiac Phoenix Rack And Pinion we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Phoenix Rack And Pinion Parts Questions & Experts Answers

- Q: How to overhaul the rack and pinion assembly in power system on Pontiac Phoenix?A:If one is to take off and reinstall rack and pinion assembly in a car, the process of removing the assembly and separating outer Tie Rods from inner tie rods would be first. After that, remove rubber boot seals and its shock dampener ring slides off from the inside tie rod housing. For you to disengage the inner tie rod assembly with a rack, wrench grip the rack and rotate the pivot housing of the tie rod counter clockwise. Next, screw off adjuster plug lock nut and separate adjuster plug by turning it anti-clockwise until it pulls out of its housing. Remove the rack bearing spring as well as rack bearing before taking away retaining ring on pinion shaft then dust cover at bottom of pinion housing. A ratchet wrench will be used to secure upper end of pinion shaft while lock nut is removed from lower end of shaft. Press threaded end of pinion shaft flush with ball bearing assembly using arbor press. Take out stub shaft dust seal, stub shaft seal plus needle bearing assembly. Align ends of rack equally from housing, mark position where pinion should leave housing and drive out pinion's shaft through press fit method using punch or drift tool positioned against outer edge surface only at location closest towards transmission case instead upwards towards oil pan on your transmission box side; however never on top part adjacent involving other gear teeth or outside wall between gears themselves themselves since this could damage those areas due rubbing against metal where contact might occur when shifting gears causing premature failure within gear engagement mechanisms like synchromesh sleeves. Remove retaining rings together valve body rings main driving force behind removal such items would usually have been use brass hammer hit out house till comes thereupon anything else pops up into place-now we can enjoy seeing what happens afterwards! Take bulkhead retaining ring off inner & outer bulkheads relating stuffs finally do same thing piston ring is taken down from above; which means either side left behind on its way down while still holding onto that part; otherwise both area need be replaced too. With appropriate device, knock out internal seal that surrounds whole rod housing so as access inside it without damaging the rest around or outside of such walls themselves within one movement. Carefully check all their conditions wear-off and damage ensuring any spoilt ones are taken off with new ones. Put together components ensuring right sealing, positioning according specified turning forces then apply fluid by means transmitted power steering system where necessity arises. Eventually, replace rack pinion assembly back into car.