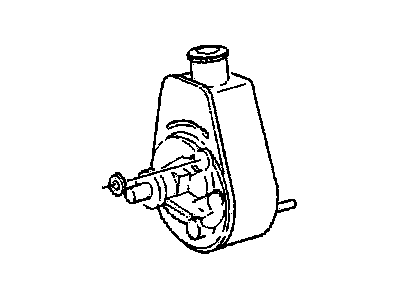

When pulling the power steering pump from a gasoline engine, the first step is to disconnect the negative terminal of the battery, and secondly, disconnect the hoses at the pump, and seal the ends, with a plastic tape, to minimize contamination or leakage; the disconnected lines should be positioned in a manner that they do not drip. Third, take off the pump belt, and depending on the model of the car one may need to take off the alternator for better access. Free the main retaining bolts and any securing members and remove the pump. Disconnect the drive belt and take out the pump pulley thus fixing it to the new pump. It is installed by fixing the pump and brackets onto the engine tightening bolts which hold the pump, connect and tighten the hose fittings, refilling the hydraulic pump with fluid, eliminating any trapped air through bleeding, installing the pump belt, checking the belt tension and reconnecting the negative terminal of the battery. Diesel engines requires, the drive belt to be pulled off and the vehicle to be lifted and supported the right front wheel needs to be also removed. In order to perform the needed work, while the engine is running, it is necessary to take off the front pulley and harmonic balancer, separate the hoses from the pump, drain the fluid from the power steering reservoir and at last, disconnect the pressure line at the pump. Disconnect the one bolt and two nuts of rear bracket, then pull out the pump and brackets, and then the pulley and brackets. For installation, the brackets and pulley have to be fixed to the pump where after fixing it; the pump has to be fixed with the help of those brackets to the engine. Set the two nuts and one bolt of the rear bracket, tightening them, connect and tighten the pressure line, and link the reservoir line to the pump. Replace the harmonic balancer re-installing the bolt with the torque of 45 lb/ft as required, then fit the pulley and tighten the bolts, fix the right front wheel then the car and tighten the lugs. Lastly add the drive belt, fill up the Power Steering Reservoir, and then bleed out the system. For bleeding, switch off the ignition, jack up the front, turn the steering wheel all the way to the left, loosen the cap of the fluid level and let the hydraulic fluid settle for a couple of minutes, turn the key for few seconds and then check whether the fluid has risen to the necessary 'cold' mark. Having an assistant confirm that the fluid level is correct, with the engine off, turn the steering wheel to the lock and back at least 20 times, start the engine, keep checking the fluid level, screw the cap on, ensure the wheels are centered, retract the front suspension and check the fluid level once again. In system testing, ensure that after properly aligning the front wheels and inflating the tires, what is the effort needed to rotate the steering wheel, With the vehicle on dry pavement and the front wheels straight depress the parking brake, turn on the engine and with the parking brake depressed move the steering wheel clockwise and counter clockwise-Note: Caution to avoid burning out of the steering fluid. Tie a spring balance for measuring the force used in turning the steering wheel full circle in each direction. Furthermore, when rotating the steering wheel to the right or left as far as it would stop slightly buzz sounds is heard indicating the functionality of the fluid flow and pressure relief valves although one has to avoid holding the wheels and turning them to the right or left for a long time as this might damage the system.

Posted by GMPartsGiant Specialist