My Garage

My Account

Cart

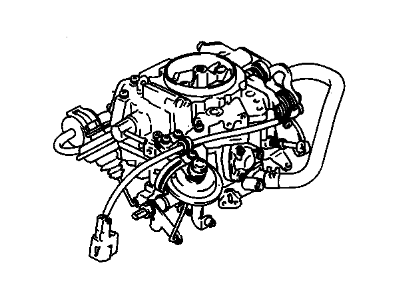

Genuine 1995 Chevrolet Tracker Carburetor

Engine Carburetor, Carb- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Carburetors found

- Product Specifications

- Other Name: CARBURETOR, Fuel

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 96069432

- Warranty: This genuine part is guaranteed by GM's factory warranty.

- Product Specifications

- Other Name: CARBURETOR, Fuel

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 96069433

- Warranty: This genuine part is guaranteed by GM's factory warranty.

1995 Chevrolet Tracker Carburetor

We are your prime source for competitively priced and high-quality OEM 1995 Chevrolet Tracker Carburetor. We provide you with parts that will allow you to save a lot of money without sacrificing quality. All our OEM parts are backed by the manufacturer's warranty and shipped out at a swift rate.

1995 Chevrolet Tracker Carburetor Parts Questions & Experts Answers

- Q: How can you diagnose and adjust a malfunctioning carburetor on 1995 Chevrolet Tracker?A: If your vehicle's engine is hard to start, does not start at all, has an unstable idle, or exhibits poor driveability, and you suspect a malfunctioning carburetor, it's advisable to take the vehicle to a dealer service department equipped for diagnosing this complex system. The following procedures are designed to assist home mechanics in verifying the operation of components, making minor adjustments, and replacing certain parts, but they are not troubleshooting procedures. To check and adjust the choke, remove the air intake case, hold the throttle open, and depress the choke plate to ensure it moves smoothly; it should be nearly fully closed if the ambient temperature is below 77 degreesF (25 degreesC) and the engine is cold. Measure the clearance between the choke plate and the carburetor bore using a feeler gauge, and if the clearances are incorrect, lubricate the choke linkage and remeasure. Start the engine and allow it to warm up; the choke should be fully open after one accelerator depression. If not, and the clearance is correct, there may be an issue with the choke linkage. If the clearance is not as specified, remove the carburetor and adjust the choke lever by removing the idle-up actuator, turning the fast idle cam counterclockwise, and locking it in place with a pin. Adjust the choke lever with pliers until the specified clearance is achieved, then reinstall the carburetor and check the choke again. For the accelerator pump, remove the air intake case, operate the throttle linkage, and observe for a healthy fuel stream from the pump discharge nozzle; if there is no squirt or only a dribble, the accelerator pump may be defective or clogged, necessitating a carburetor overhaul. For fast idle adjustment, allow the engine to cool, remove the carburetor, and ensure the fast idle cam mark aligns with the cam follower center. Disconnect the idle-up actuator hose, connect a vacuum pump, and apply approximately 16 in Hg. to measure the clearance between the actuator rod and the idle-up adjusting screw, which should be 0.10 to 0.12 in (2.5 to 3.0 mm); adjust as necessary before reinstalling the carburetor. For idle-up adjustment, run the engine to normal operating temperature, connect a tachometer to verify the idle speed, and check that the idle-up actuator rod moves down when the parking lamps are on; with the headlights on, the engine rpm should increase to 900-1000 rpm, adjusting the screw if it does not.