My Garage

My Account

Cart

Genuine Buick Century Vapor Canister

Fuel Vapor Canister- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Vapor Canisters found

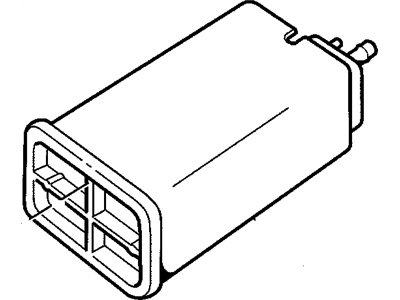

Buick Century EVAP Emission Canister Assembly

Part Number: 17113332$179.63 MSRP: $338.92You Save: $159.29 (47%)Ships in 1-2 Business DaysBuick Century Canister,Evap Emission

Part Number: 17113148$96.74 MSRP: $197.36You Save: $100.62 (51%)Ships in 1-2 Business DaysBuick Century EVAP Emission Canister Assembly

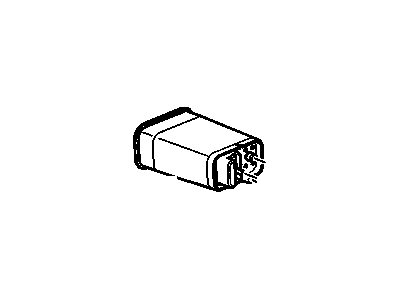

Part Number: 17113690$118.90 MSRP: $336.23You Save: $217.33 (65%)Ships in 1-3 Business Days

Buick Century Vapor Canister

Vapor Canister found in Buick Century vehicles is a component of the evaporative emissions control system commonly referred to as EVAP that is used to minimize the emission of Hydrocarbon (HC) emissions into the atmosphere. The charcoal canister is precisely this container, filled with activated charcoal with huge surface area to accommodate fuel vapors alongside tiny pores which adsorb the fuel vapors as it starts accumulating it, to release it to the engine when required. The canister is linked to the fuel tank and carburetor so that the fuel vapors when opened are allowed in through the engine with the help of the idle air control valve and air intake. In the present day's modern OBD II cars however, extra parts in the circuit such as the canister vent solenoid and the fuel tank pressure sensor are incorporated into the system as diagnostic components to help in detecting any leak in the system. III: The purpose of the Vapor Canister is to fight pollution and to guarantee the activity of the automobile's emissions control system.

Each OEM Buick Century Vapor Canister we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Buick Century Vapor Canister Parts Questions & Experts Answers

- Q: How to service and replace the vapor canister and filter on Buick Century?A:Various modifications were made to reduce escaping gasoline vapours; they include redesigned bowl vents, low bowl capacity, heat shields, and better insulation between intake manifolds and carburettors. This should eliminate the release of fuel tank vapors into the atmosphere through a carbon canister storage which holds in its storage activated carbon device which collects the vapors produced from the engine induction system every time the engine is off. When operating some of the stored fuel vapors are expelled by the intake air and burnt normally. The 231 V6 engine introduced in 1981 has an electronically controlled purge function through a solenoid connected to the Electronic Control Module (ECM) managing vacuum to the purge valve depending on the system mode. Earlier carbon canisters are generally open that sucks in air from the bottom of the canister but some of the newer models have got the closed canister system that draws its air from the air cleaner. Service entails from time to time replacing the canister filter if any, or any replacement fuel tank cap to its original type. For canister removal, hoses are disconnected, retainer screws are turned back, and the canister is lifted off the car; if the car is equipped with A/C, additional exposure buttons are loosened as well. The canister is then labeled and disconnected for use; installation, on the other hand, is done in the following order. To replace the filter, the vapor canister is taken off, then the filter is pulled out from the bottom and a replace it with a new one then the canister is replaced.

Related Buick Century Parts

Browse by Year

2005 Vapor Canister 2004 Vapor Canister 2003 Vapor Canister 2002 Vapor Canister 2001 Vapor Canister 2000 Vapor Canister 1999 Vapor Canister 1998 Vapor Canister 1997 Vapor Canister 1996 Vapor Canister 1995 Vapor Canister 1994 Vapor Canister 1993 Vapor Canister 1992 Vapor Canister 1991 Vapor Canister 1990 Vapor Canister 1989 Vapor Canister 1988 Vapor Canister 1987 Vapor Canister 1986 Vapor Canister 1985 Vapor Canister 1984 Vapor Canister 1983 Vapor Canister 1982 Vapor Canister