My Garage

My Account

Cart

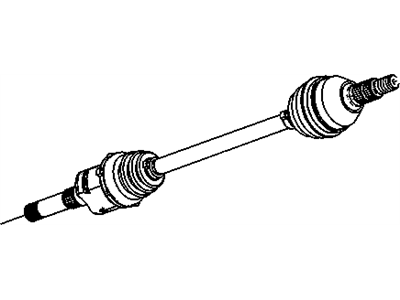

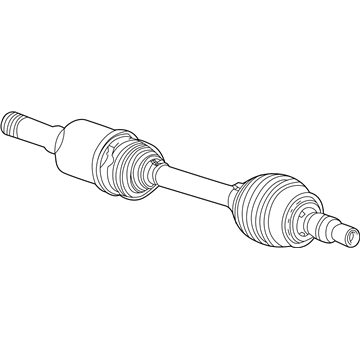

Genuine Buick Regal Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 Axle Shafts found

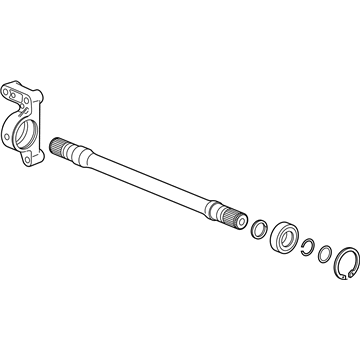

Buick Regal Rear Wheel Drive Shaft Assembly

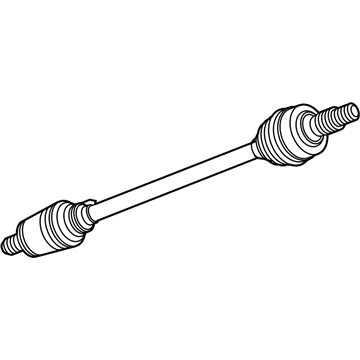

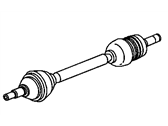

Part Number: 22823299$176.31 MSRP: $281.19You Save: $104.88 (38%)Buick Regal Front Wheel Drive Axle Shaft Assembly

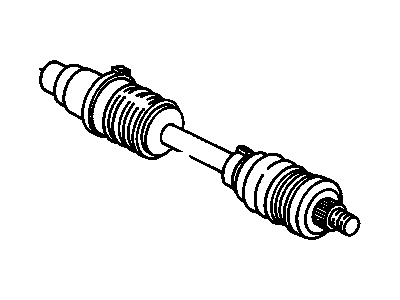

Part Number: 84628596$574.21 MSRP: $1107.07You Save: $532.86 (49%)Buick Regal Front Wheel Drive Axle Shaft Assembly

Part Number: 84628595$567.03 MSRP: $1093.18You Save: $526.15 (49%)Buick Regal Front Driver Side Half Shaft Assembly

Part Number: 84628594$432.52 MSRP: $843.12You Save: $410.60 (49%)Buick Regal Front Driver Side Half Shaft Assembly

Part Number: 84675882$409.20 MSRP: $705.87You Save: $296.67 (43%)Buick Regal Front Driver Side Half Shaft Assembly

Part Number: 84138316$179.04 MSRP: $285.55You Save: $106.51 (38%)Ships in 1-2 Business DaysBuick Regal Rear Wheel Drive Shaft Assembly

Part Number: 22823297$171.94 MSRP: $284.58You Save: $112.64 (40%)Buick Regal Front Driver Side Half Shaft Assembly

Part Number: 84675883$171.01 MSRP: $283.03You Save: $112.02 (40%)Buick Regal Shaft Assembly, Front Whl Drv Inter

Part Number: 84304681$93.77 MSRP: $155.20You Save: $61.43 (40%)Ships in 1-3 Business DaysBuick Regal Front Driver Side Half Shaft Assembly

Part Number: 84675880$247.75 MSRP: $410.06You Save: $162.31 (40%)Ships in 1-3 Business DaysBuick Regal Front Wheel Drive Shaft Kit

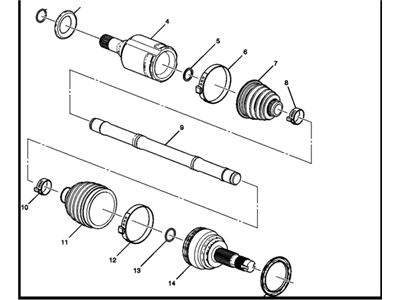

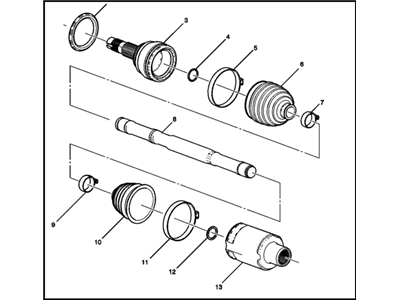

Part Number: 26054707$58.88 MSRP: $801.02You Save: $742.14 (93%)Ships in 1-2 Business DaysBuick Regal Front Drive Shaft Kit (RH)

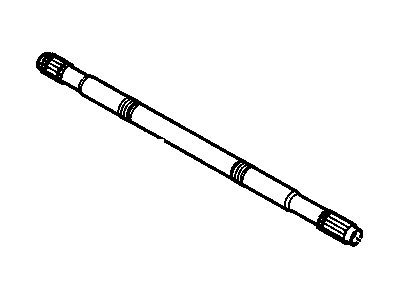

Part Number: 26008315$33.71 MSRP: $716.13You Save: $682.42 (96%)Ships in 1-2 Business DaysBuick Regal Front Wheel Drive Intermediate Shaft

Part Number: 13230371$63.08 MSRP: $99.24You Save: $36.16 (37%)Ships in 1-3 Business DaysBuick Regal Front Wheel Drive Shaft

Part Number: 7846169$47.94 MSRP: $90.46You Save: $42.52 (47%)Ships in 1-3 Business DaysBuick Regal Rear Wheel Drive Shaft Assembly

Part Number: 84675895$206.03 MSRP: $328.60You Save: $122.57 (38%)Ships in 1-3 Business DaysBuick Regal Rear Wheel Drive Shaft Assembly

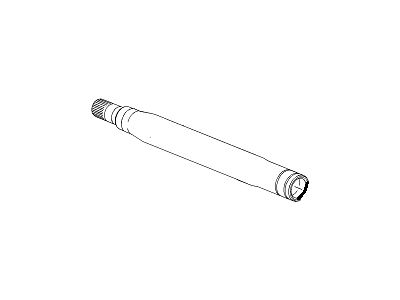

Part Number: 84675896$206.55 MSRP: $341.86You Save: $135.31 (40%)Ships in 1-3 Business DaysBuick Regal Front Wheel Drive Intermediate Shaft Assembly

Part Number: 22910264$119.80 MSRP: $189.33You Save: $69.53 (37%)Buick Regal Front Wheel Drive Intermediate Shaft Assembly

Part Number: 22910265$135.03 MSRP: $213.44You Save: $78.41 (37%)

| Page 1 of 2 |Next >

1-20 of 37 Results

Buick Regal Axle Shaft

Axle Shaft of Buick Regal vehicles is one of the vital power transmitting mechanism from the differential to the drive wheels with an independent rotation to increase the tractive force. These steel shafts are of different types including the solid axles that are applicable for trucks and older rear wheel drive vehicles, half shaft for the independent suspended vehicles. Differentials are contained by solid axles and slightly by axle shafts while half shafts transmit power from the transaxle to the wheels. Both types can wear out and hence victims of noise, vibration and possibly loss of lubricating material can be from the two types. Some key functions of the axle shafts are to bear the load of the car weight, transfer the torque and ensure proper orientation of the wheels thus making it crucial for the Buick Regal.

Each OEM Buick Regal Axle Shaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Buick Regal Axle Shaft Parts Questions & Experts Answers

- Q: How to Remove, Install and Service rear Axle Shaft, Wheel Bearing and Wheel Seal on Buick Regal?A:These cars utilize two types of drive axles, namely the C-lock and the non C-lock type whereby the difference depends on the structure of the locking system. In the C-lock type the shafts are locked by C-shaped locks that fit into slots at the inner end of the shaft while in the non C-lock type they are locked by a backing bracket plate fixed on the axle housing. The bearings used in the case of the C-lock axle comprise an outer race, bearing rollers, and roller bearing cage with snaprings while the bearings used in the case of the non C-lock axle is a unit roller bearing which is pressed on the shaft up to the shoulder. Pre-service, it is necessary to determine the axle type and the axle identification number is located on the front side of the passenger side axle tube adjacent to the differential carrier, but not for models which used 8½ in. ring gear, which have the ID on a tag under one of the differential rear cover bolts. For the non C-lock type the process starts by removing the bearing retainer plate by pounding it using chisel and the axle shaft end play check that should not be more than 0.022 in. (5mm). The removal procedures involve the detachment of the wheel, tire, and brake drum as well as the separation of the brake line, the use of the slide hammer to pull out the axle shaft and bearing assembly. The bearing retainer is then machined in several places so that it can be removed; the new bearing is then fitted and all the parts put back. For the C-lock type: The procedure is initiated by loosening and thereafter unscrewing the lockbolt and rod upon the differential; by withdrawal of the differential cover and by the unscrewing of the pinion shaft lockscrew. The axle shaft is pushed towards the center of the vehicle in order to get rid of the C-lock, always being careful not to scrap the oil seal during the extraction process. During installation, a bearing puller is applied, the new bearing is lubricated, and correct positioning of the axle shaft and C-lock must be reached in reassembling the differential and then the axle is filled with lubricant. Last of all, brake drum and wheels are reinstated and a check is made for the leaks with the help of road test.

Related Buick Regal Parts

Browse by Year

2020 Axle Shaft 2019 Axle Shaft 2018 Axle Shaft 2017 Axle Shaft 2016 Axle Shaft 2015 Axle Shaft 2014 Axle Shaft 2013 Axle Shaft 2012 Axle Shaft 2011 Axle Shaft 2004 Axle Shaft 2003 Axle Shaft 2002 Axle Shaft 2001 Axle Shaft 2000 Axle Shaft 1999 Axle Shaft 1998 Axle Shaft 1997 Axle Shaft 1996 Axle Shaft 1995 Axle Shaft 1994 Axle Shaft 1993 Axle Shaft 1992 Axle Shaft 1991 Axle Shaft 1990 Axle Shaft 1989 Axle Shaft 1988 Axle Shaft 1987 Axle Shaft 1986 Axle Shaft 1985 Axle Shaft 1984 Axle Shaft 1983 Axle Shaft 1982 Axle Shaft