My Garage

My Account

Cart

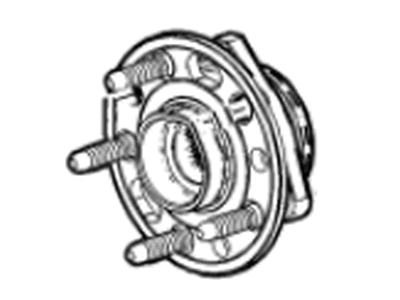

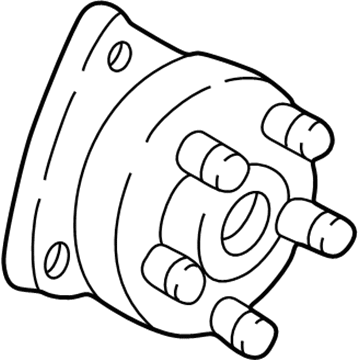

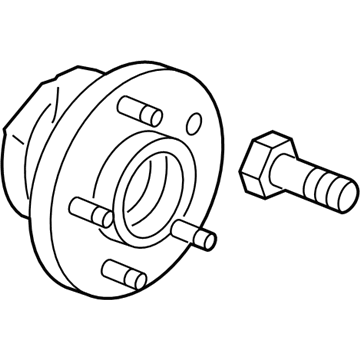

Genuine Buick Regal Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Wheel Bearings found

Buick Regal Front Wheel Bearing

Part Number: 457196$22.93 MSRP: $43.24You Save: $20.31 (47%)Ships in 1-2 Business DaysBuick Regal Rear Wheel Bearing

Part Number: 88927028$26.38 MSRP: $49.79You Save: $23.41 (48%)Ships in 1-2 Business DaysBuick Regal Front Wheel Hub

Part Number: 55573639$30.26 MSRP: $50.10You Save: $19.84 (40%)Ships in 1-2 Business DaysBuick Regal Wheel Bearing

Part Number: 14066918$10.68 MSRP: $20.16You Save: $9.48 (48%)Ships in 1-2 Business DaysBuick Regal Front Wheel Hub

Part Number: 24203440$11.93 MSRP: $19.73You Save: $7.80 (40%)Ships in 1-3 Business DaysBuick Regal HUB ASM-RR WHL

Part Number: 13546785$124.97 MSRP: $243.60You Save: $118.63 (49%)Ships in 1 Business DayBuick Regal HUB ASM,FRT WHL (W/ WHL SPD SEN) <SEE GUIDE/BFO>

Part Number: 84641365$211.47 MSRP: $412.24You Save: $200.77 (49%)Ships in 1 Business DayBuick Regal HUB,RR WHL(W/BRG)

Part Number: 13543412$96.57 MSRP: $186.60You Save: $90.03 (49%)Ships in 1-3 Business DaysBuick Regal Front Wheel Bearing

Part Number: 12429204$211.47 MSRP: $412.24You Save: $200.77 (49%)Ships in 1 Business DayBuick Regal Rear Wheel Bearing (W/ Bearing & Wheel Speed Sensor)

Part Number: 7470609$210.60 MSRP: $368.81You Save: $158.21 (43%)Buick Regal Rear Wheel Bearing (W/Wheel Speed Sensor)

Part Number: 12413091$96.55 MSRP: $175.54You Save: $78.99 (45%)Ships in 1-2 Business Days

Buick Regal Wheel Bearing

The Wheel Bearing in Buick Regal cars is an important component that helps in the rotation of the wheel and hence, improves the efficiency and safety of the car. This results in less friction and hence the wheel and tire assembly runs more smoothly with the help of these bearings which are located within the wheel hubs. Three general hub and bearing configurations have been used in Buick Regal models. The most common is the unit or integral hub and bearing assembly together with the ABS sensor which is replaced as a whole. Some of the front-wheel-drive models may additionally need the steering knuckle to be dismantled for repairs. There are also non-driven axle hubs, wherein the tapered roller bearings can be replaced and are not mounted directly to the hub. Worn or loose wheel bearings can cause a number of problems, including noise, vibration, and, most seriously, wheel detachment. This is because, for the Wheel Bearing to be in its perfect condition there is need for routine check up and any form of damage or tear should be checked.

Each OEM Buick Regal Wheel Bearing we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Buick Regal Wheel Bearing Parts Questions & Experts Answers

- Q: How to properly remove and install front wheel bearings and seals on Buick Regal?A:Pry the dust cap from the hub, taking care not to distort or damage its flange. Once the bent ends of the cotter pin are cut, grasp it and pull or pry it free of the spindle; if difficulty is encountered, gently tap on the pliers with a hammer to help free the cotter pin. Loosen and remove the castellated nut from the spindle, then remove the washer. With the nut and washer out of the way, the outer bearings may be removed from the hub, followed by pulling the hub and inner bearing assembly from the spindle. Use a small pry tool to remove the old inner bearing seal, and with the seal removed, withdraw the inner bearing from the hub. Thoroughly pack the bearing with fresh, high-temperature wheel bearing grease before installation, and apply a thin coating of fresh grease to the new inner bearing seal lip. Tighten the nut to 12 ft. lbs. (16 Nm) while gently spinning the wheel, then adjust the bearings. After adjusting, install the dust cap by tapping its flange without hammering the center. To begin, raise and support the vehicle safely on jack stands, remove the wheel assembly, and then the caliper. Pry off the dust cap, straighten or cut the cotter pin, and remove it along with the locknut. Carefully pull off the brake disc and wheel hub without dropping the outer bearing, then remove the grease inside the wheel hub. Using a brass drift, carefully drive the outer bearing race out of the hub, followed by removing the inner grease seal and bearing. Check the bearings for wear or damage and replace them if necessary. For installation, coat the inner surface of the hub with grease, grease the outer surface of the bearing race, and drift it into place in the hub. Pack the inner and outer wheel bearings with grease, and if the brake disc has been removed or replaced, lighten the retaining bolts to specification. Install the inner bearing in the hub, ensuring not to distort it, and install the oil seal with its lip facing the bearing, driving the seal on until its outer edge is even with the edge of the hub. Install the hub/disc assembly on the spindle, being careful not to damage the oil seal, then install the outer bearing, washer, and spindle nut, adjusting the bearing as needed. For adjustment, remove the wheel and dust cover, then take out the cotter pin and lock cap from the nut. Tighten the wheel bearing nut to 14 ft. lbs. (19 Nm), loosen it, and retighten to 4 ft. lbs. (5 Nm). Finally, install the lock cap and cotter pin, followed by the dust cover and wheel assembly.

Related Buick Regal Parts

Browse by Year

2020 Wheel Bearing 2019 Wheel Bearing 2018 Wheel Bearing 2017 Wheel Bearing 2016 Wheel Bearing 2015 Wheel Bearing 2014 Wheel Bearing 2013 Wheel Bearing 2012 Wheel Bearing 2011 Wheel Bearing 2004 Wheel Bearing 2003 Wheel Bearing 2002 Wheel Bearing 2001 Wheel Bearing 2000 Wheel Bearing 1999 Wheel Bearing 1998 Wheel Bearing 1997 Wheel Bearing 1996 Wheel Bearing 1995 Wheel Bearing 1994 Wheel Bearing 1993 Wheel Bearing 1992 Wheel Bearing 1991 Wheel Bearing 1990 Wheel Bearing 1989 Wheel Bearing 1988 Wheel Bearing 1987 Wheel Bearing 1986 Wheel Bearing 1985 Wheel Bearing 1984 Wheel Bearing 1983 Wheel Bearing 1982 Wheel Bearing