My Garage

My Account

Cart

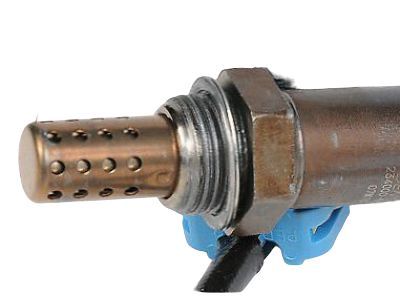

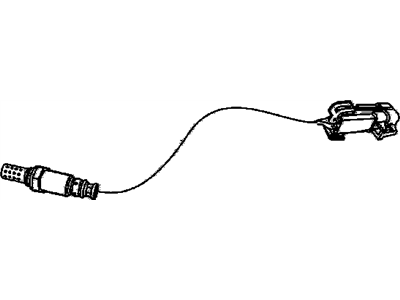

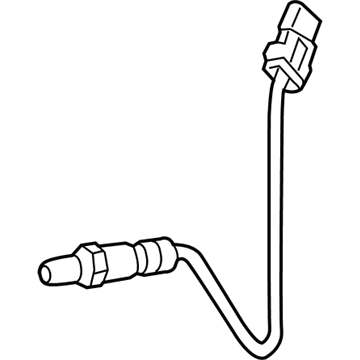

Genuine Cadillac CTS Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Oxygen Sensors found

Cadillac CTS Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12655677$49.36 MSRP: $100.70You Save: $51.34 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Post, Catalyst Bank 1)

Part Number: 12683553$54.10 MSRP: $110.38You Save: $56.28 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12634062$77.09 MSRP: $157.26You Save: $80.17 (51%)Ships in 1-3 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12652845$47.79 MSRP: $97.50You Save: $49.71 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Post, Catal)

Part Number: 12634063$58.86 MSRP: $119.02You Save: $60.16 (51%)Ships in 1-2 Business DaysCadillac CTS Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209808$72.08 MSRP: $147.04You Save: $74.96 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12569429$54.47 MSRP: $111.12You Save: $56.65 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor,Heated Oxygen(Position 1)

Part Number: 12596327$132.18 MSRP: $269.65You Save: $137.47 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12616201$99.19 MSRP: $192.34You Save: $93.15 (49%)Ships in 1-3 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Post, Catalyst B1S2)

Part Number: 12643708$38.69 MSRP: $78.92You Save: $40.23 (51%)Cadillac CTS Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12645561$45.96 MSRP: $93.76You Save: $47.80 (51%)Ships in 1-2 Business DaysCadillac CTS Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12616202$127.95 MSRP: $250.02You Save: $122.07 (49%)Ships in 1-2 Business DaysCadillac CTS Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12601266$36.15 MSRP: $73.74You Save: $37.59 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor,Heated Oxygen(Position 2)

Part Number: 12597449$91.92 MSRP: $173.44You Save: $81.52 (47%)Ships in 1-2 Business DaysCadillac CTS Sensor,Heated Oxygen(Position 1)

Part Number: 12575657$149.03 MSRP: $304.03You Save: $155.00 (51%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12580466$61.79 MSRP: $126.05You Save: $64.26 (51%)Ships in 1-2 Business DaysCadillac CTS Heated Oxygen Sensor Assembly

Part Number: 19353381$130.34 MSRP: $244.38You Save: $114.04 (47%)Ships in 1-2 Business DaysCadillac CTS Sensor Assembly, Heated Oxygen (Post, Catal)

Part Number: 12634064$76.97 MSRP: $157.02You Save: $80.05 (51%)Ships in 1-3 Business DaysCadillac CTS Sensor,Heated Oxygen(Position 2)

Part Number: 12590035$86.31 MSRP: $154.82You Save: $68.51 (45%)Cadillac CTS Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209815$101.72 MSRP: $182.46You Save: $80.74 (45%)

| Page 1 of 2 |Next >

1-20 of 31 Results

Cadillac CTS Oxygen Sensor

The Oxygen Sensor in Cadillac CTS vehicles play an important function of determining the amount of unburned Oxygen in the exhaust which is vital in controlling the air fuel mixture as well as emission levels. It uses an output of voltage signal which is proportional to the oxygen concentration and relay the information to the engine control computer to control the fuel injector timing. Most Cadillac CTS cars have both the upstream and downstream oxygen sensors with the upstream sensor primarily used to give feedback for proper functioning of the car's engine. Cadillac CTS vehicles of past years come equipped with such oxygen sensors as standard zirconium dioxide oxygen sensors as well as innovative air/fuel ratio sensors. In contrast with the traditional feedback devices that produce voltage signal when the mixture is rich or lean, air/fuel ratio sensors provide a wider operating range and use current signals. In any case, a bad oxygen sensor is likely to up emission rates and lower fuel efficiency which is why it is vital to maintain these parts in order to achieve the optimal performance from the vehicle.

Each OEM Cadillac CTS Oxygen Sensor we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac CTS Oxygen Sensor Parts Questions & Experts Answers

- Q: How can you safely service an oxygen sensor on Cadillac CTS?A:This is because it is either fitted in the exhaust manifold or pipe and due to the fact that both of these freely contract when cold, it might be practically impossible to loosen an oxygen sensor when the engine is cold. Due to the tendency of the sensor to get damaged or the mounting threads on the vehicle, start and run the engine for sometime say about 15 minutes then turn off the engine. Just be careful do not burn your self during the following procedure. Take extra care in the way that you address an oxygen sensor since it contains a permanently installed pigtail and an electrical connector that you cannot unbolt; if they are bumped or detached in any way, then the sensor is done for. Avoid getting any grease, dirt or the like to come into contact with the electrical connector of the heatsink or the louvered end of the sensor; never apply any solvent to it. Oxygen sensors are very sensitive, so they should not be dropped or moved with roughly and the silicone boot covering the sensor should be well fixed to avoid cases of melting and other operational problems. This procedure is used for upstream and downstream sensors which the upstream sensors are positioned at the exhaust manifolds or the upper portion of the exhaust manifold flange and Catalytic Converter assembly while downstream sensors are found at the lower part of the exhaust manifold/catalytic converter assembly or at the small portion of the exhaust pipe below the catalytic converter. Pull the cable away from the negative batter terminal of the vehicle. To get access to downstream sensors, lift the front of the vehicle and immobilise it with jackstands, and then unbolt the engine undercover. Find the oxygen sensor, follow the electrical lead to the connector and assess the situation, the connector should be unplugged and all harness clips should be removed. Either turning it with a wrench or using an oxygen sensor socket ,the sensor should be loosened and a slotted socket used to remove it. If reinstalling the old sensor when tightening the nuts apply anti seize compound so that next time it will be easy to remove; if replacing the oxygen sensor there is no need to apply anti seize compound because the thread has already got it. Installation is basically the removal's opposite: tightening the oxygen sensor to the proper torque setting is necessary.

Related Cadillac CTS Parts

Browse by Year

2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor