My Garage

My Account

Cart

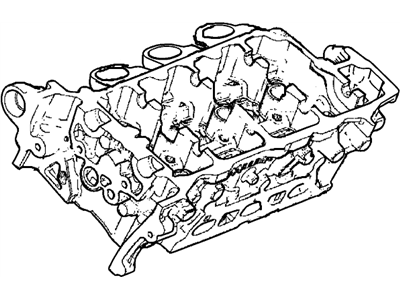

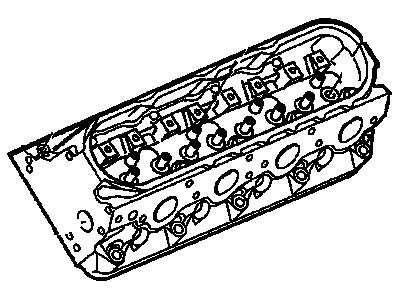

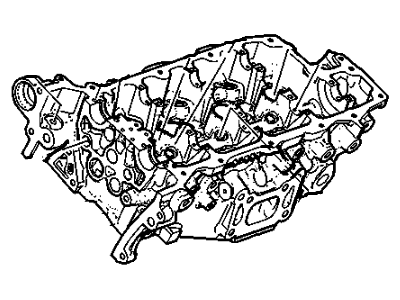

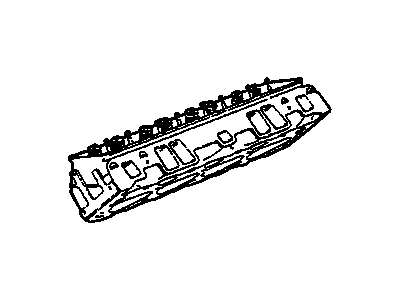

Genuine Cadillac Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

96 Cylinder Heads found

Cadillac Head Assembly, Cyl (W/ Valve)

Part Number: 12629058$1284.58 MSRP: $2048.32You Save: $763.74 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: HEAD, Engine Cylinder; Cylinder Head

- Replaced by: 12746921

Cadillac Head Assembly, Cyl (W/ Valve)

Part Number: 12675872$911.05 MSRP: $1507.86You Save: $596.81 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Vlv)

Cadillac Cylinder Head Assembly With Valve

Part Number: 55568829$490.19 MSRP: $976.88You Save: $486.69 (50%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Valve) ; Head, Engine Cylinder; Cylinder Head

Cadillac Cylinder Head Assembly

Part Number: 12581476$761.70 MSRP: $984.75You Save: $223.05 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

Cadillac Cylinder Head Assembly (Machining) (Lh Lfx W/Sai)

Part Number: 12633962$245.95 MSRP: $389.66You Save: $143.71 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (Machining) (Lh Lfx W/Sai) ; Head, Engine Cylinder; Cylinder Head

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12711770$1016.90 MSRP: $1620.46You Save: $603.56 (38%)Product Specifications- Other Name: Cylinder Head

- Replaces: 12629062, 12629064, 12582713, 12615355

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12699617$408.76 MSRP: $646.06You Save: $237.30 (37%)Product Specifications- Other Name: Cylinder Head

- Replaces: 12678972, 12620544, 12678633, 12620545

Cadillac Cylinder Head Assembly With Valve

Part Number: 12684222$721.27 MSRP: $1193.49You Save: $472.22 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Vlv); Cylinder Head

- Replaces: 12668131

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12686233$289.09 MSRP: $478.46You Save: $189.37 (40%)Product Specifications- Other Name: Cylinder Head

- Replaces: 12679109, 12679457, 12677521, 12668132, 12673745

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12698290$278.49 MSRP: $460.92You Save: $182.43 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

Cadillac Cylinder Head Assembly With Valve

Part Number: 12679101$718.11 MSRP: $1185.92You Save: $467.81 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Valve); Cylinder Head

- Replaces: 12635547

Cadillac Cylinder Head Assembly With Valve

Part Number: 55504792$596.76 MSRP: $987.68You Save: $390.92 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl (W/ Vlv); Cylinder Head

- Replaced by: 12729488

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12691728$714.79 MSRP: $862.50You Save: $147.71 (18%)Ships in 1-3 Business DaysProduct Specifications- Replaced by: 19436449

- Replaces: 12558060, 12529093

Cadillac Engine Cylinder Head

Part Number: 12562319$473.06 MSRP: $751.05You Save: $277.99 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl; Cylinder Head

Cadillac Cylinder Head Kit

Part Number: 12634220$209.71 MSRP: $328.97You Save: $119.26 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Kit,Cyl

Cadillac Cylinder Head (W/Vlvs)

Part Number: 12641095$891.09 MSRP: $1418.68You Save: $527.59 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl (W/Vlvs); Cylinder Head

- Replaces: 12635560

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12690428$1076.04 MSRP: $1713.67You Save: $637.63 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 12686739, 12626883, 12680551

- Product Specifications

- Other Name: Head,Cyl (W/Studs); Cylinder Head

- Product Specifications

- Other Name: Head,Cyl (W/Studs); Cylinder Head

Cadillac Head Assembly, Cyl (W/ Vlv)

Part Number: 12690422$796.64 MSRP: $1027.88You Save: $231.24 (23%)Product Specifications- Other Name: Cylinder Head

- Replaces: 12686736, 12648916, 12627152, 12680557, 12666599

| Page 1 of 5 |Next >

1-20 of 96 Results

Cadillac Cylinder Head

For superior quality and affordable Cadillac Cylinder Heads, consider our website. We proudly present a wide selection of genuine Cadillac Cylinder Heads at unbeatable prices. These OEM parts, supported by the manufacturer's warranty, are also eligible for our hassle-free return policy and swift delivery service.

Cadillac Cylinder Head Parts Questions & Experts Answers

- Q: What steps are necessary to remove and install cylinder heads, including the required tools and procedures in 2.8L,3.0L,3.6L V6 engine on Cadillac CTS?A:One has to get hold of a new set of MB (8 mm) and M11 (11 mm) head bolts to implement this procedure. We master this procedure under the following steps ; Start by removing the clamp that is connected to the negative terminal of the battery. Take out the plenum, intake manifold, valve covers, timing cover and the timing chains and tighten screws and retainers; record the location of the timing chain sprocket on the crankshaft. For 2.8L and 3.6L engines remove the oil dipstick tube mounting bolt and tube, disconnect all electrical connectors and ground straps from the cylinder heads and disconnect the exhaust pipe from the exhaust manifolds which will come with the cylinder heads. If left side cylinder head is to be removed then please remove P/S pump. It is removed the upper bolt in the oil filter adapter and the oil filter housing bolt at the left side cylinder head; no other oil filter housing bolts are necessary to be removed. Now for 3.0L engines take off the fuel pump, the bolts of the oil filter adapter and the adapter itself. In case of removing the left side cylinder head, then also withdraw the power steering pump and its bracket, followed by the removal of fasteners of the coolant pipe and setting aside of the pipe. Remove both exhaust manifolds from the cylinder heads, undo all electrical connection and all grounding straps from the cylinder heads. Turn the head bolts in 1/4 turn back to the sequence opposite to the lightening one to be finally removed by hand; it is also possible to compare the length and size of the bolts, which fit to be replaced by new ones. If there is resistance felt while lifting the heads off the engine, then use pry bar or long screw driver to lift it up carefully and keep the heads on blocks of wood so as to avoid damaging the gasket sealing surfaces. The machined surfaces of cylinder head and block must be free from dirt before further application, especially gasket removal solvents and gasket scraper used for removing all carbon and old gasket material from the block and cylinder head and finally clean with cloth with lacquer thinner or acetone. It also checks its block and head mating surfaces for nicks and scratches then using emery cloth slightly damaged surface then heavily damaged may have to be machined. Put the new gaskets over the dowels fitted in the block and then fit the heads of the block gently without displacing the gaskets. Apply a medium strength thread sealing compound on the threads of new 8 mm head bolts and engage the threads into the holes, tighten just enough to allow you to get your fingers between the bolt head and the metal surface, a similar operation must be done with the new 11 mm head bolts. After following the sequence as advised below tighten the bolts in four stages to the required torque and number of rotations. The rest of the process is done in the reverse of the removal ones, explained as follows. Last of all put coolant, replace oil and filter, switch on the engine and look for the engine operation, and other leaks if any, of coolant and oil.

- Q: How to Replace the Cylinder Head in V8 engine on Cadillac Escalade?A:For this procedure it will be necessary to acquire a new set of 11 mm cylinder head bolts. Start with the process of clearing out pressure on the fuel system, next step is the removal of the cable on the negative terminal of the battery and the draining of the cooling system as well. The intake manifold must be either unbolted or sometimes pulled off and for 5.3L and 6.2L engines, fuel rail(s) also to be disconnected from cylinder head(s). Remove the cylinder head bolts, exhaust manifold(s) and untighten but do not remove the exhaust pipe(s) from the exhaust manifold(s), then remove the valve cover(s) and the rocker arms and pushrods and lay them in order to assemble it back. Subsequently, take out the coolant air bleed pipe aside, the alternator with its bracket and lower the ground strap from the back of the left cylinder head. As for the right cylinder head, on 6.0L models, it is necessary to remove the dipstick tube and to disconnect the ground cables at the front of the cylinder head. Back off the head bolts in a counter-clockwise direction, one quarter turn at a time, in the reverse order that they have been tightened unbolt until they are easily removable, observe different length and sizes of bolts needed for replacement with the new ones. If the head has warped set it on the blocks of wood or if you need to remove it fully, then use pry bar or long screwdriver and lift it gently off the engine and store it properly in order not to spoil gasket sealing surfaces. As for the cylinder heads mating surfaces, they should be absolutely free of any contaminants, thus making use of gasket removal solvents and a gasket scraper in order to remove the carbon and the residual gasket material. It is recommended that the block and head mating surfaces be inspected for any sign of damage, and if there are slight imperfections then take the same emery cloth while in cases of a lot of damages, it is recommended that one takes a machine. Use a tap to chase the threads in the head bolt holes and if you do not have access to a tap then clean it with brake cleaner and compressed air as the last resort. Install the new gaskets on top of those dowels in the block, then put the heads on the block gently without moving the gaskets and put a medium strength thread locking compound on the threads of the new 8mm head bolts. Use the new 11 mm head bolts and tighten them only with your hand to a light torque and then use the recommended pattern to tighten the bolts in four passages to reach the required torque. Replace coolant pipe with new gaskets and tighten bolt and to complete the process reversed manner of its removal. Last of all pour coolant, replace the oil and filter, switch on the engine and look for normal signs and any signs of leakage.

Related Cadillac Parts

Browse by Model

ATS Cylinder Head Allante Cylinder Head Brougham Cylinder Head CT4 Cylinder Head CT5 Cylinder Head CT6 Cylinder Head CTS Cylinder Head Catera Cylinder Head Cimarron Cylinder Head DTS Cylinder Head Deville Cylinder Head ELR Cylinder Head Eldorado Cylinder Head Escalade Cylinder Head Fleetwood Cylinder Head SRX Cylinder Head STS Cylinder Head Seville Cylinder Head XLR Cylinder Head XT4 Cylinder Head XT5 Cylinder Head XT6 Cylinder Head XTS Cylinder Head