My Garage

My Account

Cart

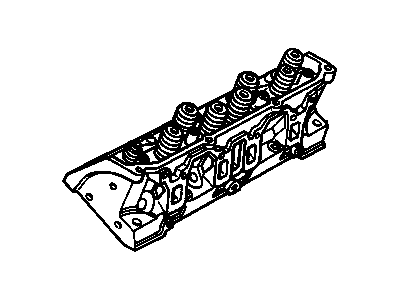

Genuine Cadillac Eldorado Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Cylinder Heads found

Cadillac Eldorado Cylinder Head

Each OEM Cadillac Eldorado Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Eldorado Cylinder Head Parts Questions & Experts Answers

- Q: What are the main types of cylinder heads used in automobiles today on Cadillac ElDorado?A:There are two main types of cylinder heads, the Overhead Valve (OHV) and the Overhead Camshaft (OHC). OHC can be further divided into Single Overhead Camshaft (SOHC) and Dual Overhead Camshaft (DOHC). Cylinder heads contain valves, guides, seats, and valve springs. Proper maintenance and tuning of the engine are crucial to prevent wear on these components. When rebuilding a cylinder head, it's ideal to replace all valves, guides, seats, and springs, but depending on the engine's condition, some parts may be reused. The disassembly process involves using a valve spring compressor tool to remove the valves, locks, and springs. Inspection is done for wear and damage, and various specialized tools are used to measure valve clearances, valve guide diameter, and spring pressure. Refinishing and repairing the cylinder head components may require machine shop assistance. Valves may need to be refaced, guides replaced, and seats machined. After thorough cleaning and inspection, the assembly process involves lubricating and inserting valves into their original positions, installing springs, retainers, valve locks, and camshafts for the respective engine type.

Related Cadillac Eldorado Parts

Browse by Year

2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1985 Cylinder Head 1984 Cylinder Head 1983 Cylinder Head 1982 Cylinder Head