My Garage

My Account

Cart

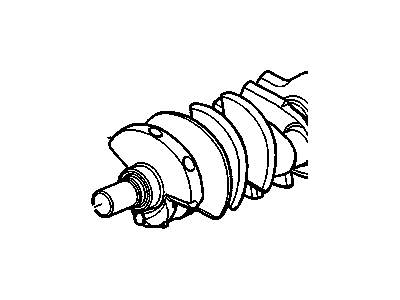

Genuine Cadillac Escalade Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Crankshafts found

Cadillac Escalade Crankshaft Assembly

Part Number: 12685650$428.35 MSRP: $708.65You Save: $280.30 (40%)Cadillac Escalade CRANKSHAFT ASM,.

Part Number: 19431873$461.48 MSRP: $763.62You Save: $302.14 (40%)Ships in 1-3 Business DaysCadillac Escalade Engine Crankshaft

Part Number: 10243070$946.66 MSRP: $1566.80You Save: $620.14 (40%)Ships in 1-3 Business DaysCadillac Escalade Crankshaft Assembly

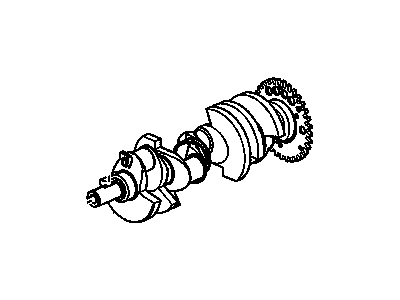

Part Number: 55510071$492.14 MSRP: $784.74You Save: $292.60 (38%)Ships in 1-3 Business DaysCadillac Escalade Crankshaft Assembly, .

Part Number: 12680208$1551.17 MSRP: $2058.69You Save: $507.52 (25%)Ships in 1-3 Business DaysCadillac Escalade Crankshaft Assembly, .

Part Number: 12712984$1059.19 MSRP: $1375.58You Save: $316.39 (23%)Cadillac Escalade Crankshaft Assembly

Part Number: 12674745$349.91 MSRP: $553.03You Save: $203.12 (37%)

Cadillac Escalade Crankshaft

Each OEM Cadillac Escalade Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and installed after the engine has been taken out on Cadillac Escalade?A:The crankshaft can only be withdrawn once the engine has been pulled out of the car, if such parts as the drive plate, the crank pulley, the timing chain, the oil pan, oil pump body, oil filter and Piston/ connecting rod assemblies have been removed. Since crankshaft endplay is going to be altered after removal, it should first be gauged with a dial indicator or feeler gauges before removal and it should range from 0.003 to 0.010 inch (0.076 to 0.254mm). To replace the bearing insert, first, loosen the main bearing cap bolts accordingly, removing the caps and merely lifting the crankshaft out without losing the bear insert. For installation, clean and check the engine block and crankshaft so as to place the new upper and lower main bearing inserts aptly so that the oil holes are in correspondence. Verify the condition of the main bearing oil clearance by means of the Plastigage, and, in case of exceeding the requirements of the specifications, repair or replace bearing inserts. The overall surface must be cleaned and a thin layer of lubricant put on the bearing surfaces before putting in the crankshaft and tightening bolts in a prescribed manner. Checks the crankshaft endplay and ensure it has fine smooth running on the crankshaft. In the process of tightening the rear main oil seal retainer, it should have specified torque and alignment when placed next to a straight edge distances between the oil seal retainer and the straight edge should be within the specified limits.

Related Cadillac Escalade Parts

Browse by Year

2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2000 Crankshaft 1999 Crankshaft