My Garage

My Account

Cart

Genuine Cadillac Escalade Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Wheel Bearings found

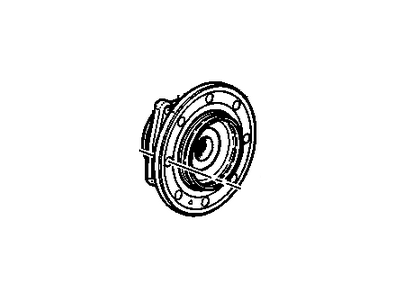

Cadillac Escalade Rear Wheel Bearing

Part Number: 9439561$78.12 MSRP: $131.28You Save: $53.16 (41%)Ships in 1-2 Business DaysCadillac Escalade Front Wheel Bearing (W/ Brg & Whl Spd Sen)

Part Number: 84459706$280.67 MSRP: $570.21You Save: $289.54 (51%)Cadillac Escalade Rear Wheel Bearing

Part Number: 9428908$70.50 MSRP: $98.04You Save: $27.54 (29%)Ships in 1-2 Business DaysCadillac Escalade Rear Wheel Bearing

Part Number: 25855296$61.81 MSRP: $120.50You Save: $58.69 (49%)Ships in 1-2 Business DaysCadillac Escalade Rear Wheel Bearing

Part Number: 25843093$266.63 MSRP: $519.76You Save: $253.13 (49%)Ships in 1-2 Business DaysCadillac Escalade Rear Wheel Bearing

Part Number: 23455948$290.59 MSRP: $571.47You Save: $280.88 (50%)Cadillac Escalade Rear Wheel Bearing

Part Number: 3977397$227.82 MSRP: $388.52You Save: $160.70 (42%)Cadillac Escalade Front Wheel Bearing

Part Number: 26041515$29.07 MSRP: $54.84You Save: $25.77 (47%)Ships in 1 Business DayCadillac Escalade Front Wheel Bearing

Part Number: 26066885$30.77 MSRP: $58.06You Save: $27.29 (47%)Ships in 1-2 Business DaysCadillac Escalade Differential Bearing

Part Number: 9436881$57.47 MSRP: $145.36You Save: $87.89 (61%)Ships in 1-3 Business DaysCadillac Escalade Rear Wheel Bearing

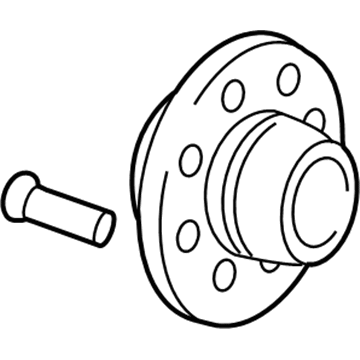

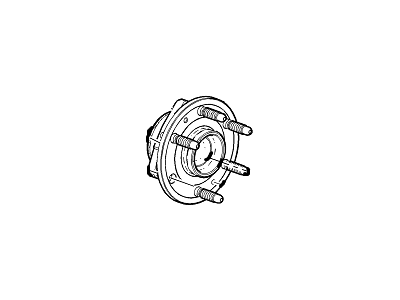

Part Number: 352982$240.56 MSRP: $421.27You Save: $180.71 (43%)Cadillac Escalade Hub Assembly, Front Whl (W/ Brg & Whl Spd Sen)

Part Number: 84869190$183.11 MSRP: $356.94You Save: $173.83 (49%)Cadillac Escalade Hub Assembly, Front Whl (W/ Brg & Whl Spd Sen)

Part Number: 84964448$206.89 MSRP: $426.79You Save: $219.90 (52%)Cadillac Escalade Wheel Bearing

Part Number: 25855295$76.42 MSRP: $150.28You Save: $73.86 (50%)Ships in 1-2 Business DaysCadillac Escalade Hub Assembly, Front Whl (W/ Brg & Whl Spd Sen)

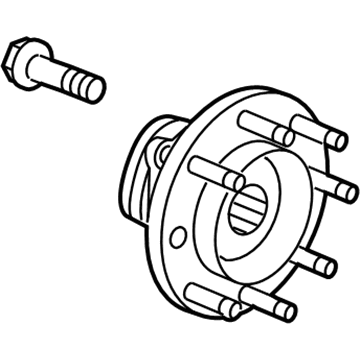

Part Number: 84856653$242.57 MSRP: $472.84You Save: $230.27 (49%)Ships in 1-2 Business DaysCadillac Escalade Front Wheel Hub

Part Number: 26041516$4.97 MSRP: $9.04You Save: $4.07 (46%)Ships in 1-2 Business DaysCadillac Escalade HUB,RR WHL(W/BRG)

Part Number: 13536121$129.43 MSRP: $235.32You Save: $105.89 (45%)Cadillac Escalade Bearing Assembly, Front Diff

Part Number: 23243752$10.06 MSRP: $18.98You Save: $8.92 (47%)Ships in 1-3 Business DaysCadillac Escalade Rear Wheel Bearing

Part Number: 20945052$257.11 MSRP: $463.25You Save: $206.14 (45%)

| Page 1 of 2 |Next >

1-20 of 27 Results

Cadillac Escalade Wheel Bearing

The Wheel Bearing in Cadillac Escalade vehicles is used to let the wheel rotate without experiencing drag while at the same time providing safety to the driver. In the majority of current designs, the hub and bearing assembly is integrated or unitized and usually includes the ABS sensor and is removed as a complete assembly. There are some front-wheel-drive Escalade models where the steering knuckle may have to be pulled out for service, whereas nondriven axle hubs incorporate replaceable tapered roller bearings. Inadequate or damaged Wheel Bearings may cause noise, and vibration and at worst, wheel loss hence requiring regular check up. To Cadillac Escalade owners it is recommended that, Wheel Bearings' condition should be checked for roughness and play in order to sustain the worthy performance of the vehicle as well as safety. However, if replacement is to be done then proper fitment and alignment of the bearings is important to perform its function effectively.

Each OEM Cadillac Escalade Wheel Bearing we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Wheel Bearing Parts Questions & Experts Answers

- Q: How to remove and reassemble the rear Wheel Bearing,Wheel Hub and Wheel Seal on Cadillac Escalade?A:To get at the axleshaft on the other hand, the rear wheel lug nuts should be loosened, the rear of the vehicle should be raised, and safely supported on jackstands while the front wheels are blocked and the rear wheels are removed. Then, you should unbolt the brake caliper and bracket together and then you should take off brake disc. Remove the retaining ring and key from the end of the axle housing, then unscrew the adjusting nut which can be done with a special socket, which is always available at any auto spare parts market. Pop the hub assembly straight off the axle tube, you can then eliminate the oil seal from the rear part of the hub. Remove all the bearings, hub, and the axle tube; clean them with the solvent after which the bearings should be sprayed using brake system cleaner this will hasten the drying process. For bearings, examine them visually for cracks, wear and damage; in addition to this examine the axle tube flange and the studs, hub splines for the same. In case they are weary or impaired in anyway, then they should be replaced by fresh ones. If you would like to pull apart the hub even further, use a hammer and a long bar or a drift punch to knock in the inner bearing cup then you remove the retaining ring and knock in the outer bearing cup. Remove the old sealing compound from the seal bore in the hub and do a check on the brake disc. The hub can be reassembled by reversing the breakdown process, and using the appropriate bearing driver for the new bearing cups. The bearings and the areas of contact between axle tube and the H kindly smeared with wheel bearing grease until fully absorbed. During installation, the axle housing oil deflector should be fitted properly, the hub assembly should be placed simply on the axle tube not damaging the oil seals and the adjusting nut should be fitted while adjusting the bearings. Twist the hub in every direction to make certain it moves easily, after that, tighten the adjusting nut to 50 ft-lbs using torque wrench and like wise use a special socket. Loosen the nut to the turn where it is loose then use hand to tighten the nut. If required, loosen the nut in anticlockwise fashion until the corresponding slot is aligned with the key slot in the spindle and then fix the key in position but do not turn the nut more than fifth slot allow. Lastly, fit the retaining ring, ensure that there is very little, if any, endplay with the hub assembly at the same time ensuring that it rotates smoothly, fit the axleshaft before lifting the vehicle off the ways.

Related Cadillac Escalade Parts

Browse by Year

2024 Wheel Bearing 2023 Wheel Bearing 2022 Wheel Bearing 2021 Wheel Bearing 2020 Wheel Bearing 2019 Wheel Bearing 2018 Wheel Bearing 2017 Wheel Bearing 2016 Wheel Bearing 2015 Wheel Bearing 2014 Wheel Bearing 2013 Wheel Bearing 2012 Wheel Bearing 2011 Wheel Bearing 2010 Wheel Bearing 2009 Wheel Bearing 2008 Wheel Bearing 2007 Wheel Bearing 2006 Wheel Bearing 2005 Wheel Bearing 2004 Wheel Bearing 2003 Wheel Bearing 2002 Wheel Bearing 2000 Wheel Bearing 1999 Wheel Bearing