My Garage

My Account

Cart

Genuine Cadillac PCV Valve Hose

Positive Crankcase Ventilation Valve Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

106 PCV Valve Hoses found

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

- Replaces: 12662657, 12654851

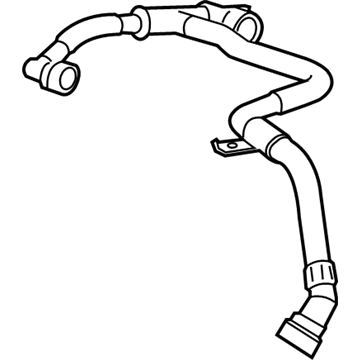

Cadillac Tube Assembly, Int Air Duct Pcv

Part Number: 12687313$12.10 MSRP: $24.68You Save: $12.58 (51%)Product Specifications- Other Name: PCV Tube

- Replaces: 12670880, 12670874

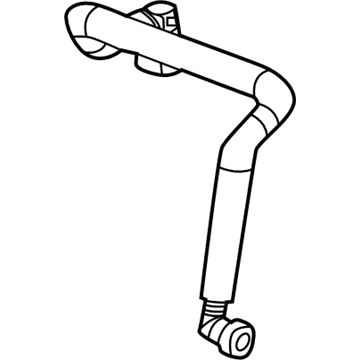

Cadillac PVC Tube Assembly

Part Number: 12603992$51.43 MSRP: $85.12You Save: $33.69 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation

Cadillac PVC Tube Assembly

Part Number: 12670791$20.53 MSRP: $38.74You Save: $18.21 (48%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation; Breather Tube, PCV Tube

- Replaces: 12619985

Cadillac PVC Tube Assembly

Part Number: 12670793$20.53 MSRP: $38.74You Save: $18.21 (48%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation; Breather Tube, PCV Tube

- Replaces: 12638607

Cadillac PVC Tube Assembly

Part Number: 12655013$29.35 MSRP: $55.38You Save: $26.03 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Valve

- Replaces: 12563269

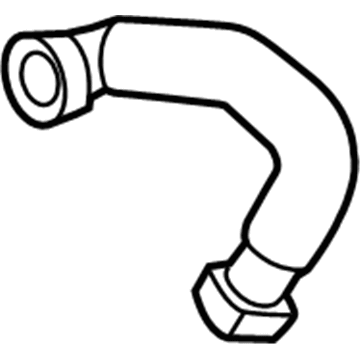

Cadillac Tube,Pcv

Part Number: 12620142$18.50 MSRP: $34.90You Save: $16.40 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

Cadillac Tube Assembly, Pcv Foul Air

Part Number: 12703915$38.10 MSRP: $77.72You Save: $39.62 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: PCV Tube

- Replaces: 12701760, 12664809

- Product Specifications

- Other Name: Tube Assembly, Pcv; PCV Tube

- Replaces: 12670876, 12664356, 12670879, 12670882

Cadillac PVC Tube Assembly

Part Number: 12690758$13.56 MSRP: $25.58You Save: $12.02 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tube Assembly, Pcv; PCV Tube

- Replaces: 12670881, 12670878, 12668976, 12687310, 12670875

Cadillac Tube Assembly, Pcv (To Fresh Air Duct)

Part Number: 12670879$19.24 MSRP: $36.30You Save: $17.06 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation

- Replaced by: 12681424

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

- Replaced by: 19435537

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Valve

Cadillac Tube Assembly, Pcv (Foul Air)

Part Number: 12638437$25.05 MSRP: $44.94You Save: $19.89 (45%)Product Specifications- Other Name: TUBE, Engine Crankcase Ventilation

- Replaces: 12609021

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

- Product Specifications

- Other Name: Tube Assembly, Pcv; PCV Tube

- Replaces: 25201118, 12673869

- Product Specifications

- Other Name: HOSE, Engine Crankcase Ventilation

- Product Specifications

- Replaces: 12654076, 12681589

| Page 1 of 6 |Next >

1-20 of 106 Results

Cadillac PCV Valve Hose

For superior quality and affordable Cadillac PCV Valve Hoses, consider our website. We proudly present a wide selection of genuine Cadillac PCV Valve Hoses at unbeatable prices. These OEM parts, supported by the manufacturer's warranty, are also eligible for our hassle-free return policy and swift delivery service.

Cadillac PCV Valve Hose Parts Questions & Experts Answers

- Q: What are the effects of high temperatures on rubber and plastic PCV valve hoses in engine systems, and what inspection practices should be followed on Cadillac CTS?A:Hoses for engine, accessory and emission systems are made of rubber and plastics that tend to wear out and harden when exposed to high heat under the hood and hence require regular check up for cracks, loose clamps, material hardening and leakage. Most hoses have clamps on them, which should be tightened to prevent leakage; if there are no clamps it should be ensured that the hose has not swollen at the fitting or has become rigid. To cut down the emission of hydrocarbons, the gases produced by crankcase blow-by are drawn through the PCV hoses and discharged at the intake manifold to mix with the fresh incoming air for combust. PCV hoses to be checked for cracks and then if blocked, should be cleaned with the help of solvent. These hoses, which usually come in colours, need certain thickness of the wall and certain temperature resistance; when replacing, make certain that the new hoses are made from the same material as the old ones. Hoses sometimes need to be disconnected for checking and identifying them helps in fixing them back in the correct manner. Some of the things that should be included in the inspection process of the T-fittings include whether the plastic has cracks or distortion which is likely to lead to leak. A small piece of vacuum hose can be used as a stethoscope to diagnose faulty vacuum hoses by putting this check probe up to your mouth and hearing, or rather listening to hissing. Fuel lines are usually connected under pressure and as such, if you need to remove the fuel lines be ready to mop the floor because fuel will drip. Look for signs of deterioration of flexible fuel lines particularly in regions of bends and fittings and when replacing it, only use hoses suitable for the particular fuel injection system. Some fuel lines have clips that allow the usage of easy to disconnect equipment on the fuel line. The metal lines used for the fuel lines under the body should be checked for bends, crimps or crack lines. If the fuel line is a metal type, it has to be replaced with the steel tubing, while copper and aluminum do not possess the necessary for resisting the vibrations of the engine. Moreover, check metal brake lines at the master cylinder and brake proportioning unit for crack, and loose fittings because if any spot of leakage is observed in brake fluid, then it means the brake system requires inspection.

Related Cadillac Parts

Browse by Model

ATS PCV Valve Hose Allante PCV Valve Hose Brougham PCV Valve Hose CT4 PCV Valve Hose CT5 PCV Valve Hose CT6 PCV Valve Hose CTS PCV Valve Hose Catera PCV Valve Hose Cimarron PCV Valve Hose DTS PCV Valve Hose Deville PCV Valve Hose Eldorado PCV Valve Hose Escalade PCV Valve Hose Fleetwood PCV Valve Hose SRX PCV Valve Hose STS PCV Valve Hose Seville PCV Valve Hose XLR PCV Valve Hose XT4 PCV Valve Hose XT5 PCV Valve Hose XT6 PCV Valve Hose XTS PCV Valve Hose