My Garage

My Account

Cart

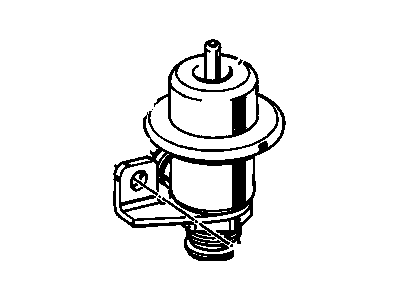

Genuine Chevrolet Beretta Fuel Pressure Regulator

Fuel Tank Pressure Regulator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Fuel Pressure Regulators found

Chevrolet Beretta Regulator,Fuel Pressure

Part Number: 17120665$122.95 MSRP: $250.81You Save: $127.86 (51%)Ships in 1-2 Business DaysChevrolet Beretta REGULATOR KIT, Fuel Injection

Part Number: 17091218$96.05 MSRP: $138.03You Save: $41.98 (31%)

Chevrolet Beretta Fuel Pressure Regulator

Chevrolet Beretta specifically has Fuel Pressure Regulator plays this critical role of regulating fuel pressure in the fuel injection system. It is attached at fuel rail and contains spring as well as the diaphragm which controls the flow of the fuel according to the vacuum produced by the engine. In other words, when idle, the regulator permits the un-needed fuel output to circulate back to the tank but when throttle is increased, the vacuum is reduced and the flow is limited in order to generate the necessary pressure for delivering fuel. Since the start of Chevrolet Beretta production, different versions of Fuel Pressure Regulators have been employed which include pressure reducing type as well as back pressure. The primary distinction lies in their operation: pressure reducing regulators are normally open and lower input pressure while back-pressure regulators are normally closed and sustain a set pressure. Larger injectors or higher volume pumps will cause the air / fuel mixture to be set by adjustable regulators, for while the original equipment regulators are fixed, larger injectors will require adjustment.

Each OEM Chevrolet Beretta Fuel Pressure Regulator we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Beretta Fuel Pressure Regulator Parts Questions & Experts Answers

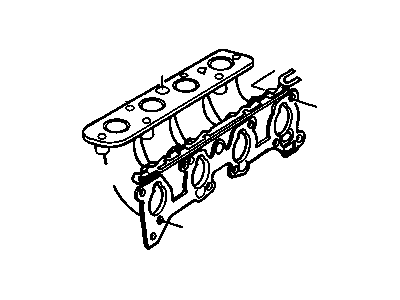

- Q: How to remove and install Fuel Injector,Fuel Pressure Regulator,Idle Control Valve,Mass Air Flow Sensor,Throttle Body and Throttle Position Sensor on Chevrolet Beretta?A:The initial step of the throttle body procedure is given by the disconnection of the cable that is connected to the battery's negative terminal, where models with the Delco Loc II audio system feature a lockout function. Remove the connectors of the IAC valve, TPS, the vacuum hoses and the throttle cable, the breather hose and the air inlet duct. Before removing the bolts of the throttle body, the coolant should be drained and the coolant lines should be disconnected, the throttle body should also be detached. Fit in the new throttle body and the gasket by using the appropriate size of bolts and tighten them to the recommended degree. The rest of the process is the process of assembling. In case of the IAC valve, the electrical connector should be disconnected, the attaching screws to be unbolted and a new rubber O-ring must be installed after the washing of the special sealing surface. Ensure the pintle position is correct before whole assembly and fit a new O-ring with engine oil before fitting the IAC valve squarely. Replacement of the TPS requires the appointment of a dealer or repair shop with a scan tool for the correct adjustment. For the plenum on V6 and 1992 and later 2.2L engines and removal you have to: Pull the negative battery cable, remove vacuum hoses with their connectors and mark, remove the throttle cable bracket. EGR valve & throttle body have to be detached together with the plastic spark plug-wire shield and the plenum bolts. Undue care should be taken when removing the plenum; and the gaskets should be cleaned to remove any sign of the old gasket material before the new gaskets are fitted and the plenum replaced with bolts. The fuel rail on the other hand requires the negative battery cable to be removed, plenum if found to be removed and fuel lines disconnected by turning them around the backup wrench. Disconnect the injector electrical connect and unplug then take out the fuel rail bolts and then take out fuel rail with the injectors. Before servicing of the injectors clean the area around the injectors, then unlock the injector clip and pull out the injectors and should check and replace the O-ring seals if applicable. Fit new O-rings lubricated with engine drive, tighten the injectors by means of retainer clips and depending on a type of the engine unload necessary fittings and scews for the fuel pressure regulator in this Updated procedure all gaskets and seals must be replaced. Last, lubricate the injector O-ring seals and then install fuel rail and energize the fuel system for leaks. Mass Air Flow (MAF) sensor can be removed from the car by unscrewing the mounting screw, disconnecting the electrical connector and detaching the air duct before lifting the MAF sensor out of the car, though should be handled carefully should one intend to re-install it. Installation procedure is just the reverse of removal process.