My Garage

My Account

Cart

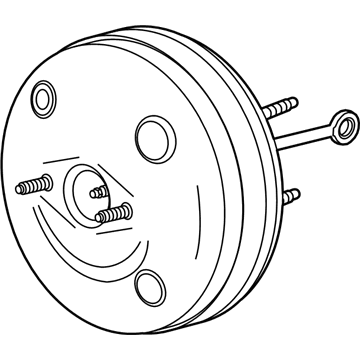

Genuine Chevrolet Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

229 Brake Boosters found

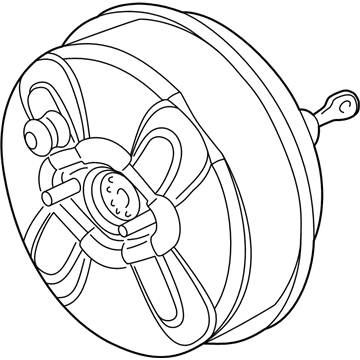

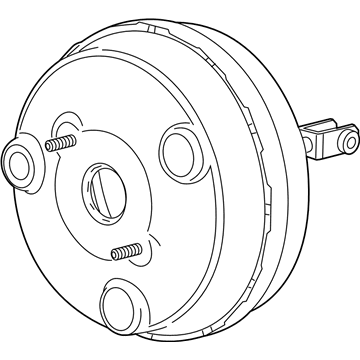

Chevrolet Power Brake Booster Assembly

Part Number: 19371362$295.70 MSRP: $581.50You Save: $285.80 (50%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Asm,P/B; Booster Assembly, Brake Booster

- Replaces: 15854061, 20940395, 20759772, 20940393, 25802513

- Product Specifications

- Other Name: Booster Assembly, Brake Booster

- Replaces: 15212480, 15218247, 15854059, 15183760, 15126867, 15814411

Chevrolet Power Brake Booster Assembly

Part Number: 19371355$401.96 MSRP: $781.92You Save: $379.96 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Asm,P/B; Booster Assembly, Brake Booster

- Replaces: 15167549, 15183759, 15854058, 15212479, 15218248, 15126866, 15814410

- Product Specifications

- Other Name: Booster Assembly, Brake Booster

- Replaces: 25790711, 20774171, 20941664

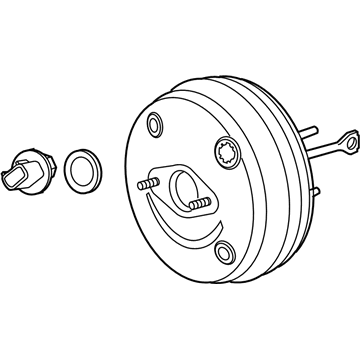

Chevrolet Power Brake Booster Kit(Vacuum)

Part Number: 22908218$806.33 MSRP: $1571.74You Save: $765.41 (49%)Product Specifications- Other Name: Booster Kit,Power Brake(Vacuum); Booster Assembly, Brake Booster, Power Booster

- Replaces: 13317102

Chevrolet Power Brake Booster Kit(Vacuum)

Part Number: 84251010$377.52 MSRP: $645.54You Save: $268.02 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Kit, Power Brake (Vacuum); Booster Assembly, Brake Booster

- Replaced by: 84749955

- Replaces: 23311737, 23234989

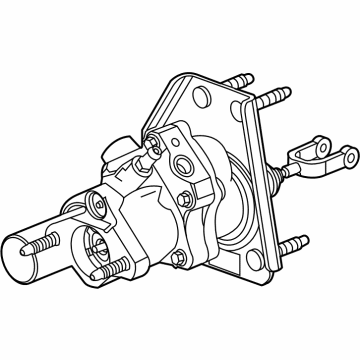

Chevrolet Power Brake Booster Assembly

Part Number: 84474523$442.38 MSRP: $777.64You Save: $335.26 (44%)Product Specifications- Other Name: Booster Assembly, P/B; Booster Assembly, Brake Booster

- Replaces: 22869378, 84031702, 22800156

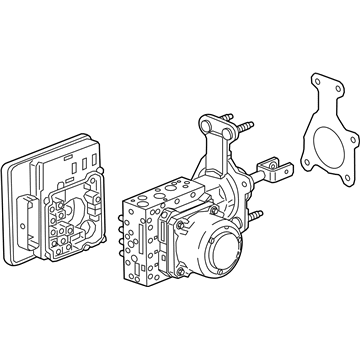

- Product Specifications

- Other Name: CYLINDER ASM-BRK MAS(W/P/B BOOS&ELEK BRK), Master Cylinder, Master Cylinder Assembly; Brake Master Cylinder with Power Brake Booster and Brake Booster Control Module

- Replaced by: 85077522

- Replaces: 84514095, 84514094, 84933511, 84821586, 85124356, 84702004, 84821585, 84933510, 84702005

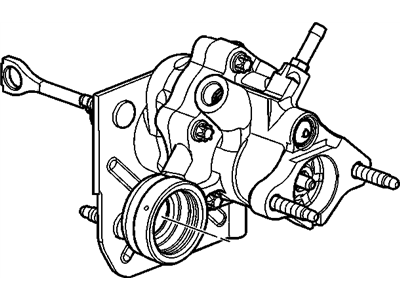

Chevrolet Booster Assembly, P/B

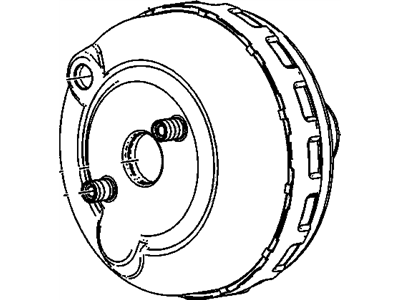

Part Number: 84602473$105.71 MSRP: $207.87You Save: $102.16 (50%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster, Booster Assembly, Brake Booster

- Replaces: 23135220

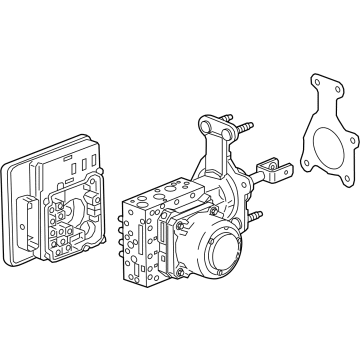

Chevrolet CYLINDER ASM-BRK MAS(W/P/B BOOS&ELEK BRK)

Part Number: 87815018$904.64 MSRP: $1442.81You Save: $538.17 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder, Master Cylinder Assembly

- Replaced by: 85697531

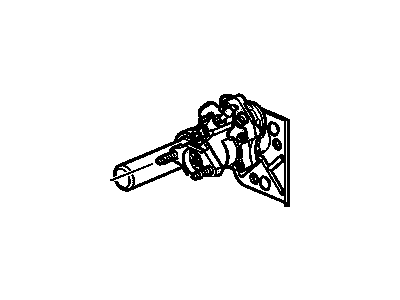

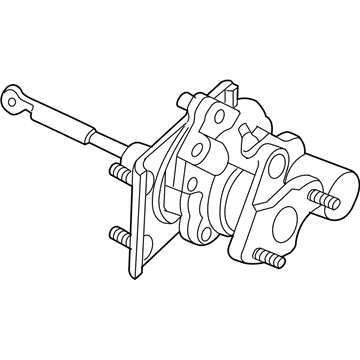

Chevrolet BOOSTER ASM,P/B

Part Number: 19432805$577.81 MSRP: $1119.51You Save: $541.70 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake Booster, Master Cylinder

- Replaces: 84164392, 22745515, 19417216, 22881356

Chevrolet Power Brake Booster Assembly

Part Number: 84609220$251.95 MSRP: $491.15You Save: $239.20 (49%)Product Specifications- Other Name: Booster Assembly, P/B; Booster Assembly, Brake Booster

- Product Specifications

- Other Name: Booster Assembly, Brake Booster

- Replaces: 20877277, 84164393, 19417211, 20896308

Chevrolet Power Brake Booster Assembly

Part Number: 19371367$257.36 MSRP: $710.50You Save: $453.14 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Asm,P/B; Booster Assembly, Brake Booster

- Replaces: 22800155, 22869377

Chevrolet BOOSTER KIT-P/B (VAC)

Part Number: 84927728$156.22 MSRP: $307.22You Save: $151.00 (50%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake Booster

- Replaces: 23358495, 84038602

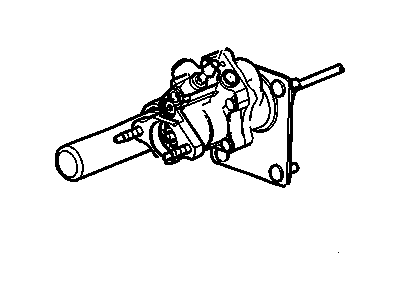

Chevrolet BOOSTER ASM,P/B

Part Number: 19432804$419.22 MSRP: $817.20You Save: $397.98 (49%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake Booster

- Replaces: 19417213, 84164390, 15886470

Chevrolet Booster Assembly, P/B

Part Number: 84635614$128.85 MSRP: $234.28You Save: $105.43 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Booster, Power Booster

- Replaced by: 19432798

Chevrolet BOOSTER ASM,P/B

Part Number: 19432806$464.88 MSRP: $906.20You Save: $441.32 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake Booster

- Replaces: 19417219, 25827889, 84177387

Chevrolet Power Brake Booster Kit(Vacuum)

Part Number: 84730945$113.79 MSRP: $221.82You Save: $108.03 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Booster Kit, P/B (Vac); Brake Booster, Power Booster

- Replaces: 84486952, 23371176

- Product Specifications

- Replaces: 10367085, 15804966, 19209324, 19418518, 84177388, 15840835, 15250764

| Page 1 of 12 |Next >

1-20 of 229 Results

Chevrolet Brake Booster

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet Brake Boosters at competitive prices in the market. All our OEM Chevrolet Brake Boosters are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet Brake Booster Parts Questions & Experts Answers

- Q: What is the function and operation of a power brake booster on Chevrolet Caprice?A:An assistor, power brake booster, has been included on all models since and can utilize vacuum from the manifold of the engine. When there is fault in the booster, enough vacuum is reserved to help with two or three brake application, additional pressure is then required in the hydraulic brake system. Different kinds of power brake boosters consist of Delco-Moraine and Bendix, and both works on the same mechanism. In case brakes are released and in the same time the engine is on, vacuum is present on the both sides of the power piston, simultaneously, the air filters enters and is stopped in the air valve. When the driver applies the brake, pressing the brake pedal, the push rod gets translated, which leads to the admission of atmospheric air and consequent forward stroke of the power piston that redistributes the oil in the hydraulic master cylinder and at the same time feeds back to the driver. Namely, the power piston remains in that position once the desired level of braking force has been developed; the brake pedal pressure will alter it. Letting go of the pedal pressure opens the air valve and it comes into contact with the power piston, thus sealing the admission of atmospheric air, and also resets the power piston to its original position which then releases the hydraulic pressure. In case of vacuum failure, the brake pedal is useable for emergency braking, which demands higher pressure much as standard brake system. This involves the examination of hoses and the air filter of the power brake unit The dismantling of a power brake unit can be best done, with power brake special tools while it is more advisable to replace power brake unit than overhaul it, after a fault has been discovered.

- Q: What is the function and operation of a power brake booster on Chevrolet El Camino?A:A power brake booster is standard across all models and came with the vacuum system derived from the manifold of the engine. Ideally, vacuum is accumulated in case of a failure in the booster to manage two or three brake applications after which more force such as in any hydraulic system is applied to the brake pedal. Other types of power brake boosters are the Delco-Moraine and Bendix boosters and both work in a similar manner. When the brakes are released the vacuum is possible on both sides of the power piston, the air through the filter enters, and in turn, any air in the circuit is drawn through a narrow passage and into the intake manifold by means of a check valve. When the brake pedal is pressed, this pushes the push rod that in turns moves the air valve thus opens to allow air from the environment into the housing so as to motivate the power piston to operate the hydraulic master piston. As pressure increases the hydraulic reaction plate comes in contact with the reaction levers to feedback to the pedal that the degree of brake has been applied for the driver to feel. When the required braking force has been realized, the power piston stops moving in case of alteration of pressure on the pedal. Venting pedal pressure returns the air valve to engage the power piston thus sealing off supply of atmospheric air and with the help of piston, the hydraulic pressure inside the brake system is relieved by receding into the rear housing. Should there be vacuum failure for instance when the engine is off or when there is a bad vacuum line then the brake pedal can still be applied though at a higher pedal pressure that a normal system. The power brake unit does not need any special degree of maintenance, apart from the inspection of the hoses and the air filter located beneath the boot on the side of the push rod from the pedal. Removal of the power brake unit requires special tools and it is best to get a new or re-manufactured unit as replacement on the occurrence of a problem if not warrantied by the company.

Related Chevrolet Parts

Browse by Model

Astro Brake Booster Avalanche Brake Booster Aveo Brake Booster Beretta Brake Booster Blazer Brake Booster Blazer EV Brake Booster Bolt EV Brake Booster C10 Brake Booster C1500 Brake Booster C20 Brake Booster C2500 Brake Booster C30 Brake Booster C3500 Brake Booster Cadet Brake Booster Camaro Brake Booster Caprice Brake Booster Captiva Sport Brake Booster Cavalier Brake Booster Celebrity Brake Booster Citation Brake Booster City Express Brake Booster Cobalt Brake Booster Colorado Brake Booster Corsica Brake Booster Corvette Brake Booster Cruze Brake Booster El Camino Brake Booster Equinox Brake Booster Express Brake Booster G10 Brake Booster G20 Brake Booster G30 Brake Booster HHR Brake Booster Impala Brake Booster K10 Brake Booster K1500 Brake Booster K20 Brake Booster K2500 Brake Booster K30 Brake Booster K3500 Brake Booster Lumina Brake Booster Malibu Brake Booster Metro Brake Booster Monte Carlo Brake Booster Orlando Brake Booster P20 Brake Booster P30 Brake Booster Prizm Brake Booster R10 Brake Booster R20 Brake Booster R2500 Brake Booster R30 Brake Booster R3500 Brake Booster S10 Brake Booster SS Brake Booster SSR Brake Booster Silverado Brake Booster Silverado EV Brake Booster Sonic Brake Booster Spark Brake Booster Spectrum Brake Booster Sprint Brake Booster Storm Brake Booster Suburban Brake Booster Tahoe Brake Booster Tracker Brake Booster Trailblazer Brake Booster Traverse Brake Booster Trax Brake Booster Uplander Brake Booster V10 Brake Booster V20 Brake Booster V30 Brake Booster V3500 Brake Booster Venture Brake Booster