My Garage

My Account

Cart

Genuine Chevrolet Cruze Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Boosters found

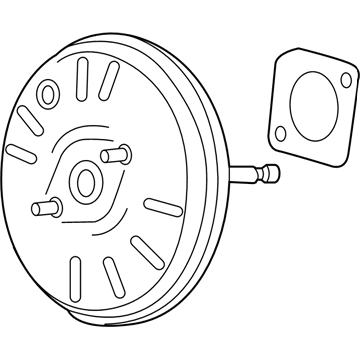

Chevrolet Cruze Booster Kit, P/B (Vac)

Part Number: 42704202$80.72 MSRP: $157.35You Save: $76.63 (49%)Ships in 1-2 Business DaysChevrolet Cruze Power Brake Booster Kit(Vacuum)

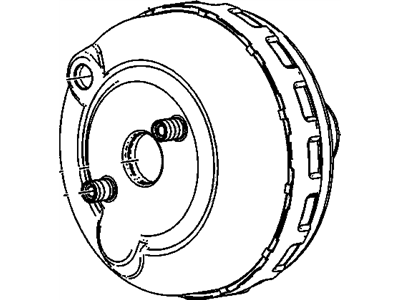

Part Number: 13409893$483.65 MSRP: $857.92You Save: $374.27 (44%)

Chevrolet Cruze Brake Booster

The Brake Booster in the automobiles of Chevrolet Cruze is significant for improving the braking power by reducing the pressure to be applied by a driver. It mainly employs a vacuum operation with the help of the pressure difference between engine vacuum and normal atmosphere or air pressure, which boosts up the force applied to the brake pedal. It makes it easier for the driver to engage the brakes as compared to the other systems making this system to be efficient and effective in braking. The models of Chevrolet Cruze may have different kinds of brake boosters in terms of their functioning namely vacuum boosters and hydraulic boosters. Vacuum boosters are commonly used and very dependable but do on occasion fail while hydraulic boosters utilize the pressure of the fluid used in power steering or an electic motor. The use of single or dual diaphragm boosters determines the power assistance given and the size of the diameter can give more assistance but due to space in the engine compartment small ones may be preferred.

Each OEM Chevrolet Cruze Brake Booster we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Cruze Brake Booster Parts Questions & Experts Answers

- Q: How to perform an operating check and replace the power brake booster on Chevrolet Cruze?A:To perform an operating check, depress the brake pedal several times with the engine off to ensure there is no change in the pedal reserve distance, then start the engine; if the pedal goes down slightly, operation is normal. For the airtightness check, start the engine and turn it off after one or two minutes, then depress the brake pedal several times slowly; if the pedal goes down farther the first time but gradually rises after the second or third depression, the booster is airtight. While the engine is running, depress the brake pedal and stop the engine with the pedal depressed; if there is no change in the pedal reserve travel after holding the pedal for 30 seconds, the booster is airtight. When removing and installing, be cautious as brake fluid will damage paint; cover all painted surfaces and avoid spilling fluid. The power brake booster is not rebuildable and must be replaced if a problem develops. Disconnect the cable from the negative terminal of the battery and remove the master cylinder. Disconnect the vacuum hose check valve and electrical connector from the power brake booster, then mark and disconnect the lines to the EBCM/EBTCM module, capping the lines and plugging the openings. Disconnect the electrical connectors, remove the mounting bolts and module, and in the passenger compartment, remove the driver's-side under-dash panel. Disconnect the pushrod from the click connector clip securing the booster pushrod to the brake pedal arm and replace the click connector. Remove the booster-to-firewall through bolts from inside the engine compartment, guide the booster unit away from the firewall and out of the engine compartment, and retrieve the gasket if it isn't stuck to the booster. To install the booster, place it into position using a new gasket and tighten the bolts to the specified torque. Lubricate the pushrod pin on the brake pedal arm with multi-purpose grease, connect the pushrod to the brake pedal, and install a new click connector clip. Reconnect the vacuum hose, install the EBCM/EBTCM module ensuring the lines are tightened securely, then connect the electrical connectors and install the master cylinder. Bleed the brakes starting with the master cylinder, then the ABS EBCM/EBTCM, and finally all four wheels. Reconnect the battery and carefully test the operation of the brakes before placing the vehicle in normal service.