My Garage

My Account

Cart

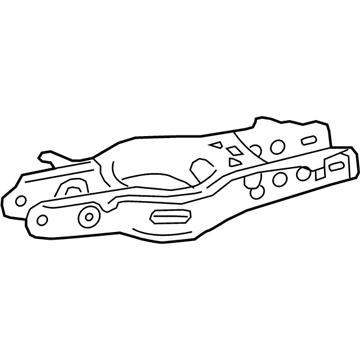

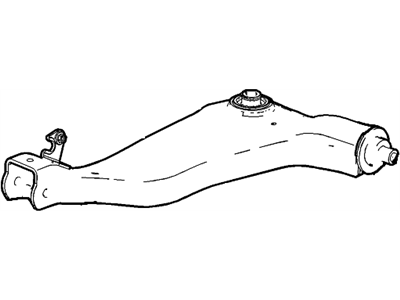

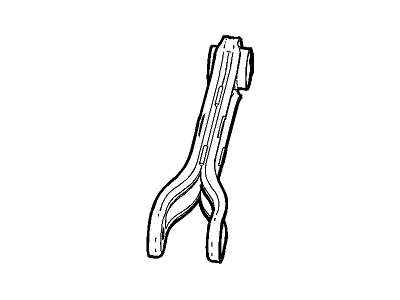

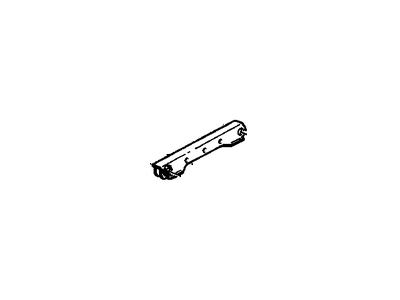

Genuine Chevrolet Camaro Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

39 Control Arms found

Chevrolet Camaro Front Lower Control Arm Assembly Front

Part Number: 92236899$132.64 MSRP: $226.80You Save: $94.16 (42%)Ships in 1-3 Business DaysChevrolet Camaro Front Lower Control Rear Arm

Part Number: 20951300$134.41 MSRP: $226.45You Save: $92.04 (41%)Ships in 1-2 Business DaysChevrolet Camaro Front Lower Control Rear Arm

Part Number: 20951301$129.72 MSRP: $220.49You Save: $90.77 (42%)Ships in 1-2 Business DaysChevrolet Camaro Front Lower Control Arm Assembly Front

Part Number: 92236898$143.50 MSRP: $245.38You Save: $101.88 (42%)Ships in 1-3 Business DaysChevrolet Camaro Rear Suspension Lower Control Arm

Part Number: 20942237$54.22 MSRP: $92.72You Save: $38.50 (42%)Ships in 1-2 Business DaysChevrolet Camaro Rear Lower Suspension Control Arm Assembly

Part Number: 84382227$54.95 MSRP: $94.79You Save: $39.84 (43%)Ships in 1-2 Business DaysChevrolet Camaro Rear Upper Suspension Control Arm Assembly

Part Number: 23110245$101.87 MSRP: $174.21You Save: $72.34 (42%)Ships in 1-2 Business DaysChevrolet Camaro Rear Upper Suspension Control Arm Assembly

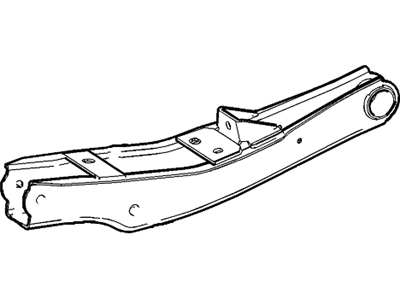

Part Number: 23110246$97.35 MSRP: $167.93You Save: $70.58 (43%)Ships in 1-2 Business DaysChevrolet Camaro Rear Suspension Trailing Arm Assembly

Part Number: 92246140$21.65 MSRP: $35.82You Save: $14.17 (40%)Ships in 1-2 Business DaysChevrolet Camaro Rear Lower Suspension Control Arm Assembly

Part Number: 84382226$54.95 MSRP: $94.79You Save: $39.84 (43%)Ships in 1-2 Business DaysChevrolet Camaro Rear Lower Control Arm Assembly

Part Number: 10251391$118.67 MSRP: $189.27You Save: $70.60 (38%)Ships in 1-2 Business DaysChevrolet Camaro Front Lower Control Arm Assembly Rear

Part Number: 23105014$25.53 MSRP: $120.81You Save: $95.28 (79%)Ships in 1-2 Business DaysChevrolet Camaro Rear Upper Suspension Control Arm Assembly

Part Number: 23104902$116.29 MSRP: $153.99You Save: $37.70 (25%)Ships in 1-2 Business DaysChevrolet Camaro Rear Upper Suspension Control Arm Assembly

Part Number: 23104903$89.88 MSRP: $148.77You Save: $58.89 (40%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 39 Results

Chevrolet Camaro Control Arm

This component known as the Control Arm is situated between the front wheel assembly and the Chevrolet Camaro car frame helping in the smooth handling of the vehicle and also it provides the required comfort to the passengers in terms of ride quality. Normally, one or two control arms subsist each wheel that is linked to the car's underframe at one end and to the wheels at the other extremity. The design provides a justifiable means of independently positioning the wheel in the radial sense, and thus usually employs a rubber bush to rotate. There are two types of control arms used in Chevrolet Camaro models that have been assembled in the car, the A-arm is used and the triangular wishbone. The A-arm relies on a single pivot point of operation and might need other links to restrain its travel, while the wishbone configuration is comparatively versatile and doesn't need those links. Unlike other types of suspensions, track control arms in MacPherson strut suspensions are positioned vertically relative to a vehicle's longitudinal axis, with an additional diagonal radius rod for control of motion.

Each OEM Chevrolet Camaro Control Arm we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Control Arm Parts Questions & Experts Answers

- Q: How to remove and replace front control arms on Chevrolet Camaro?A:Lug nuts, vehicle, raise, and jack stands, These are the procedures followed when trying to remove the wheel of the car. Subsequently, remove the wheel. If the vehicle has brake cooling ducts then to get to the pivot bolt may require the removal of the duct. Take out the front control arm to subframe pivot bolt and nut, and also uncouple the nut at the lower ball joint. To remove the ball joint, one has to use the ball joint removal tool to get the ball stud out of the knuckle, the ball stud should not be tighten with the nut hence a wrench should be used. After that, take off the front lower control arm. For the rear control arm, if so equipped the suspension position sensor link needs to be removed along with the ball joint nut, then a ball joint removal tool must be used to take the ball stud off the knuckle while holding it with a wrench. Fit the new bush into the front subframe in exactly the same way as the rear subframe, then put the control arm back into the position but do not install the nut and stud that connects the control arm to the subframe. Also, check for distortion of the control arms and whether the bushings need replacement and if there is bending in the control arms; extend particular attention to this without endeavouring to bend back the control arm if you find that it is curved. The process of later installation is the reverse of the removal procedure and this entails tightening of all fasteners to the right torque status. Do not fully torque the pivot nuts and bolts; instead, raise the out of end of the control arm to mimic normal ride height. Last but not the least, fit the wheel along with lug nuts and lower the vehicle and finally carry out the torqueing of the lug nuts. After fitting the new pads it is recommended that the front wheel alignment is checked and adjusted, if required.

Related Chevrolet Camaro Parts

Browse by Year

2024 Control Arm 2023 Control Arm 2022 Control Arm 2021 Control Arm 2020 Control Arm 2019 Control Arm 2018 Control Arm 2017 Control Arm 2016 Control Arm 2015 Control Arm 2014 Control Arm 2013 Control Arm 2012 Control Arm 2011 Control Arm 2010 Control Arm 2002 Control Arm 2001 Control Arm 2000 Control Arm 1999 Control Arm 1998 Control Arm 1997 Control Arm 1996 Control Arm 1995 Control Arm 1994 Control Arm 1993 Control Arm 1992 Control Arm 1991 Control Arm 1990 Control Arm 1989 Control Arm 1988 Control Arm 1987 Control Arm 1986 Control Arm 1985 Control Arm 1984 Control Arm 1983 Control Arm 1982 Control Arm