My Garage

My Account

Cart

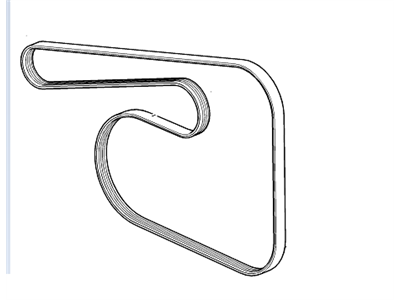

Genuine Chevrolet Camaro Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Drive Belts found

Chevrolet Camaro Belt, Water Pump & A/C Compressor & Generator

Part Number: 12647764$25.99 MSRP: $46.63You Save: $20.64 (45%)Ships in 1-2 Business DaysChevrolet Camaro Belt, Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12639035$41.10 MSRP: $73.72You Save: $32.62 (45%)Ships in 1-3 Business DaysChevrolet Camaro Belt, Water Pump & Generator

Part Number: 12643218$20.69 MSRP: $37.11You Save: $16.42 (45%)Ships in 1-3 Business DaysChevrolet Camaro Belt, A/C Cmpr

Part Number: 12685983$16.97 MSRP: $29.72You Save: $12.75 (43%)Ships in 1-3 Business DaysChevrolet Camaro Belt, Supercharge (Service)

Part Number: 12676726$41.19 MSRP: $73.90You Save: $32.71 (45%)Chevrolet Camaro Belt,Water Pump & Generator

Part Number: 12642400$30.82 MSRP: $55.28You Save: $24.46 (45%)Ships in 1-3 Business DaysChevrolet Camaro Belt, A/C Compressor

Part Number: 12622244$18.27 MSRP: $32.78You Save: $14.51 (45%)Ships in 1-2 Business DaysChevrolet Camaro Belt, Water Pump & Generator

Part Number: 12641123$33.55 MSRP: $60.18You Save: $26.63 (45%)Chevrolet Camaro Belt,Water Pump & Generator & P/S Pump

Part Number: 12639280$35.84 MSRP: $64.28You Save: $28.44 (45%)Ships in 1-3 Business DaysChevrolet Camaro Belt, Supercharge

Part Number: 12668317$82.54 MSRP: $148.06You Save: $65.52 (45%)Ships in 1-3 Business DaysChevrolet Camaro Belt,Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 19172684$35.32 MSRP: $66.65You Save: $31.33 (48%)Ships in 1-3 Business DaysChevrolet Camaro Belt,Generator & A/C Compressor & P/S Pump

Part Number: 19244956$18.41 MSRP: $33.02You Save: $14.61 (45%)Chevrolet Camaro Belt, Water Pump & Generator & P/S Pump

Part Number: 12569527$31.25 MSRP: $56.07You Save: $24.82 (45%)Chevrolet Camaro Belt Kit,A/C Compressor

Part Number: 19260807$44.46 MSRP: $79.72You Save: $35.26 (45%)Chevrolet Camaro Belt, Generator & A/C Compressor

Part Number: 12664598$19.35 MSRP: $34.70You Save: $15.35 (45%)Chevrolet Camaro Belt, Water Pump & Generator

Part Number: 12654814$27.80 MSRP: $49.86You Save: $22.06 (45%)

| Page 1 of 2 |Next >

1-20 of 26 Results

Chevrolet Camaro Drive Belt

The Drive Belt in Chevrolet Camaro automobiles is vital for joining the engine to many parts comprising of the alternator, A/C compressor among others. Usually there is a serpentine belt which is used, where it stretches around these parts and connects them to the crankshaft pulley. This design ensures that proper power transmission is attained with Drive Belts holding a lifespan of approximately 100000 miles though they may need to be replaced in case they are destroyed. Different types of Drive Belts have been used in Chevrolet Camaro over the years with the early models using v-belts and the later models using multi groove belts, both of which possessed some advantages. V-belts increase the amount of traction and belt's strength and, on the other hand, multi-groove belts increase the belt's flexibility and productivity. There are the timing belts, which have the teeth to ensure the non-slip movement and applied in certain applications of the Camaro. These Drive Belts models have grown in functionality reflecting technologies that make them perform better and be reliable for Chevrolet Camaro.

Each OEM Chevrolet Camaro Drive Belt we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Drive Belt Parts Questions & Experts Answers

- Q: What is the importance of drive belts in engine operation and how should they be inspected and replaced on Chevrolet Camaro?A:Located at the front of the vehicle, the drive belt(s) are essential accessories for the function of the engine, by rotating various parts, including the alternator, power steering pump, water pump, an air conditioning compressor, and supercharger for the ZL1 models. There are different layouts according to year of engine, from one to several belts, for which it is necessary to monitor the degree of wear due to their operational purpose and material. One is self-adjustable and by observing wear indicator marks on the tensioner body adjustments can be done visually; if the indicator mark is outside the working range then replacement is required. To look through all the length of the belt it has to be rotated by turning the engine and with this movement checking for cracks, fraying and glazing of the belt surface as well as to check for damage on the pulleys. Minor cracks on the ribbed belts are allowable in essence as long as the cracks are not intensive or overly deep in this case; the belts have to be replaced. For V6 engines, this means having to remove not less than the air intake duct and the resonator in order to release tension on the drive belt and replace it. V8 engines are the same as the above, with different procedures for 2011 and earlier models, and 2012 and later models including the supercharger drive belt. The air conditioning compressor drive belt can only be unbolt since it has to be slit so as to emplace the new conveyor belt into proper position and must fit the pulley grooves correctly. The drive belt tensioner can be removed by unbolted from the engine; conversely, installation is done by the reverse of removal while making sure that all bolts are tightened to the recommended torque.

Related Chevrolet Camaro Parts

Browse by Year

2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1990 Drive Belt 1989 Drive Belt 1988 Drive Belt 1987 Drive Belt 1986 Drive Belt 1985 Drive Belt 1984 Drive Belt 1983 Drive Belt 1982 Drive Belt