My Garage

My Account

Cart

Genuine Chevrolet Camaro Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Oxygen Sensors found

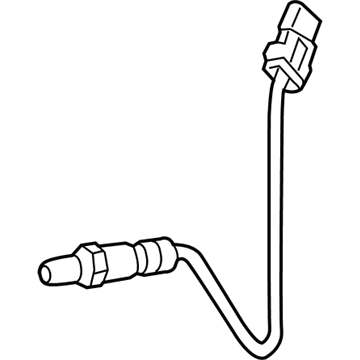

Chevrolet Camaro Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12655677$49.36 MSRP: $100.70You Save: $51.34 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Post, Catalyst Bank 1)

Part Number: 12683553$54.10 MSRP: $110.38You Save: $56.28 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12634062$77.09 MSRP: $157.26You Save: $80.17 (51%)Ships in 1-3 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12652845$47.79 MSRP: $97.50You Save: $49.71 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Pre, Cataly)

Part Number: 12640453$49.23 MSRP: $100.42You Save: $51.19 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Post, Catal)

Part Number: 12634063$58.86 MSRP: $119.02You Save: $60.16 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Position 3)

Part Number: 12609457$50.13 MSRP: $102.26You Save: $52.13 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor,Heated Oxygen(Position 2)

Part Number: 12617332$88.05 MSRP: $166.14You Save: $78.09 (47%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Asm,Heated Oxygen

Part Number: 19178924$67.75 MSRP: $138.20You Save: $70.45 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Position 1)

Part Number: 12616201$99.19 MSRP: $192.34You Save: $93.15 (49%)Ships in 1-3 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Post, Catalyst B1S2)

Part Number: 12643708$38.69 MSRP: $78.92You Save: $40.23 (51%)Chevrolet Camaro Sensor Asm,Heated Oxygen

Part Number: 19178958$61.38 MSRP: $125.22You Save: $63.84 (51%)Ships in 1-2 Business DaysChevrolet Camaro Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12616202$127.95 MSRP: $250.02You Save: $122.07 (49%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Asm,Heated Oxygen

Part Number: 19178930$66.12 MSRP: $134.88You Save: $68.76 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Post, Catalyst Bank 1)

Part Number: 12666671$40.44 MSRP: $76.30You Save: $35.86 (47%)Ships in 1-2 Business DaysChevrolet Camaro Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12616203$97.26 MSRP: $198.42You Save: $101.16 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen (Post, Catal)

Part Number: 12634064$76.97 MSRP: $157.02You Save: $80.05 (51%)Ships in 1-3 Business DaysChevrolet Camaro Sensor Asm,Heated Oxygen<Do Not Use, Contact Tech Specialist

Part Number: 19355308$71.00 MSRP: $144.84You Save: $73.84 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor Assembly, Heated Oxygen(Pre, Catalyst Bank 1 Se)

Part Number: 12666672$35.78 MSRP: $73.00You Save: $37.22 (51%)Ships in 1-2 Business DaysChevrolet Camaro Sensor,Exhaust Oxygen

Part Number: 19211437$18.91 MSRP: $33.92You Save: $15.01 (45%)| Page 1 of 2 |Next >1-20 of 24 Results

Chevrolet Camaro Oxygen Sensor

The Oxygen Sensor of Chevrolet Camaro cars is used to measure amounts of oxygen contained in the exhaust system, so as to control the air-fuel mixture in order to enhance the vehicle's performance and at the same time bring down emission levels. This sensor assists the engine control module in performance through the formulation of information and real time knowing regarding the functioning of the vehicle. Chevrolet Camaro models employ zirconia and titania based oxygen sensors with different working principles. Narrow-band and wide-band zirconia sensors are widely applied to precise fuel control, titania sensors vary resistance rather than creating voltage. These sensors play a pivotal role in performance due to their failure, this results in high emission rates as well as high fuel consumption in Chevelle Camaro.

Each OEM Chevrolet Camaro Oxygen Sensor we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Oxygen Sensor Parts Questions & Experts Answers

- Q: How can you properly service an oxygen sensor on Chevrolet Camaro?A:Since an oxygen sensor is mounted in the exhaust manifold or pipe, both of which shrink when cold, you can spend a long time trying to loosen it with your hands when the engine is cold. It is better not to endanger the sensor or the threads on which it is mounted; start the engine and let it run for connection for a few minutes and shut it down. Attention should be paid not to be burnt during the following procedure. When servicing the oxygen sensor, one must be very careful since it has a permanently attached pigtail and an electrical connector that can neither be removed nor replaced; if either is damaged, the sensor will be useless. Do not allow grease, dirt, or other foreign substances to come in contact with the electrical connector or the long slender finned section at the end of the sensor and do not use any type of cleaning solvent on the unit. These oxygen sensors are very sensitive, avoid dropping or roughly transporting them, and always fix the silicone boot in the correct manner to prevent melting or operational problems. This procedure is common to both upstream and downstream sensors the upstream sensors are fitted in the exhaust pipes immediately after the exhaust pipe flange at the cylinder head for V6 engines or exhaust manifold for V8 engines while the downstream sensors are fitted in the exhaust system after the Catalytic Converter. Remove the black cable from the negative terminal of the battery. On V6 models, upstream sensors must be accessed from the top of the vehicle while downstream sensors can be accessed from the bottom of the vehicle In V8 models all the sensors are accessed from the bottom of the vehicle. Except for the removal of an upstream sensor on a V6 model, lift the front of the car and place it on jackstands, and then, take off the engine under cover. Identify the location of the oxygen sensor, follow the wires of the sensor till the connector and remove it, which will remove any clips on the harness too. Locate the oxygen sensor and using a wrench or an oxygen sensor socket, unscrew the sensor, although for removal, use a slotted socket. If reinstalling the old sensor, the use of anti-seize compound at the threads will be appropriate incase one may find it hard to remove the sensor next time, for the new sensor will already have a layer of anti-seize compound on its threads. Removal is the reverse of installation, where one makes sure that the oxygen sensor is tightened to a certain torque.

Related Chevrolet Camaro Parts

Browse by Year

2024 Oxygen Sensor 2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2002 Oxygen Sensor 2001 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor 1998 Oxygen Sensor 1997 Oxygen Sensor 1996 Oxygen Sensor 1995 Oxygen Sensor 1994 Oxygen Sensor 1993 Oxygen Sensor 1992 Oxygen Sensor 1991 Oxygen Sensor 1990 Oxygen Sensor 1989 Oxygen Sensor 1988 Oxygen Sensor 1987 Oxygen Sensor 1986 Oxygen Sensor 1985 Oxygen Sensor 1984 Oxygen Sensor 1983 Oxygen Sensor 1982 Oxygen Sensor