My Garage

My Account

Cart

Genuine Chevrolet Colorado Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Engine Mounts found

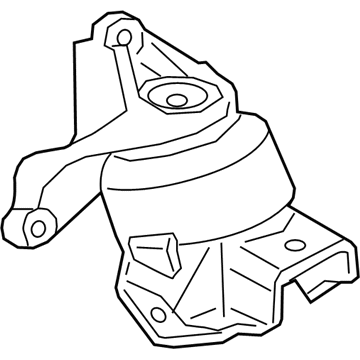

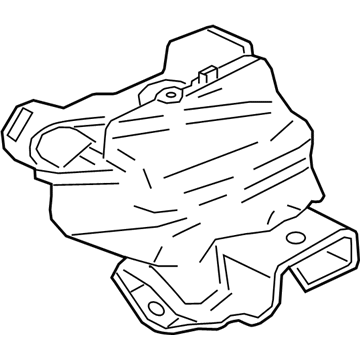

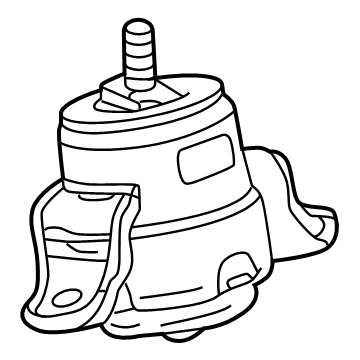

Chevrolet Colorado Engine Mount Assembly

Part Number: 23195922$124.04 MSRP: $212.11You Save: $88.07 (42%)Ships in 1-2 Business DaysChevrolet Colorado Engine Mount Assembly

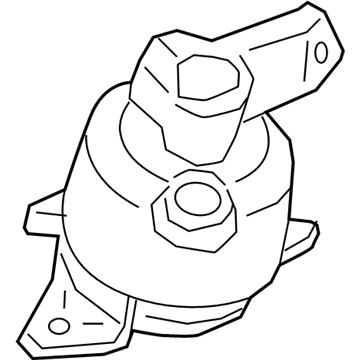

Part Number: 23436325$94.54 MSRP: $163.07You Save: $68.53 (43%)Ships in 1-3 Business DaysChevrolet Colorado Engine Mount Assembly

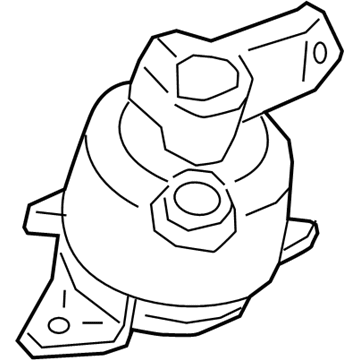

Part Number: 23436324$94.54 MSRP: $163.07You Save: $68.53 (43%)Ships in 1-3 Business DaysChevrolet Colorado Engine Mount

Part Number: 15925796$66.27 MSRP: $113.32You Save: $47.05 (42%)Ships in 1-2 Business DaysChevrolet Colorado Engine Mount

Part Number: 97287678$71.66 MSRP: $122.55You Save: $50.89 (42%)Ships in 1-2 Business DaysChevrolet Colorado Engine Mount Assembly

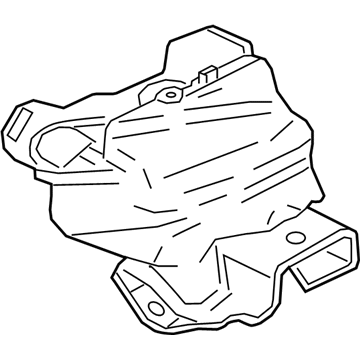

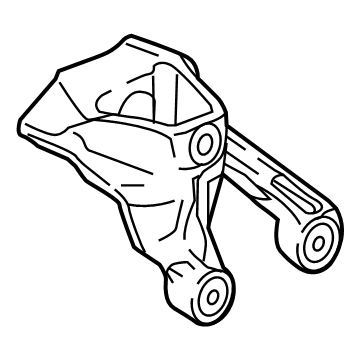

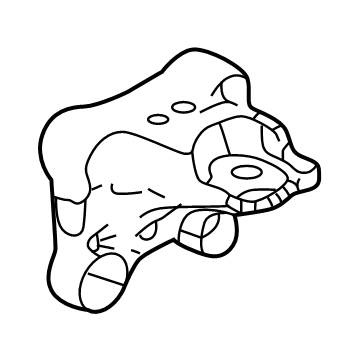

Part Number: 23405712$89.00 MSRP: $147.29You Save: $58.29 (40%)Ships in 1-3 Business DaysChevrolet Colorado Bracket, Engine Mount Engine Side

Part Number: 84060315$67.83 MSRP: $112.26You Save: $44.43 (40%)Chevrolet Colorado Engine Mount Assembly

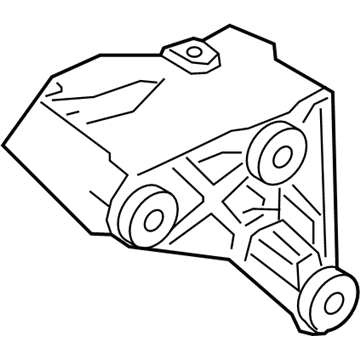

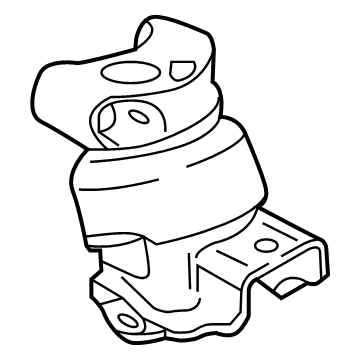

Part Number: 23195919$75.22 MSRP: $152.98You Save: $77.76 (51%)Chevrolet Colorado Engine Mount Assembly

Part Number: 23226127$116.70 MSRP: $199.55You Save: $82.85 (42%)Ships in 1-2 Business DaysChevrolet Colorado Engine Mount Assembly

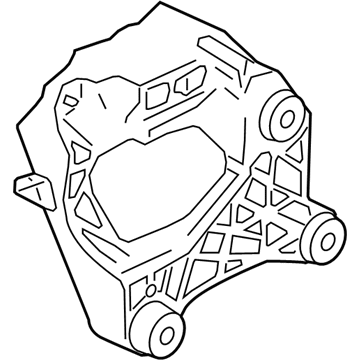

Part Number: 23195921$117.14 MSRP: $200.30You Save: $83.16 (42%)Ships in 1-2 Business DaysChevrolet Colorado Bracket, Engine Mount Engine Side

Part Number: 23373843$71.54 MSRP: $112.56You Save: $41.02 (37%)Ships in 1-3 Business DaysChevrolet Colorado Bracket, Eng Mt Eng Si

Part Number: 23247708$72.11 MSRP: $113.45You Save: $41.34 (37%)Chevrolet Colorado Transmission Mount

Part Number: 15138532$42.35 MSRP: $71.79You Save: $29.44 (42%)Ships in 1-2 Business DaysChevrolet Colorado BRACKET-ENG MT ENG SI

Part Number: 84653919$52.76 MSRP: $83.02You Save: $30.26 (37%)Ships in 1-2 Business DaysChevrolet Colorado BRACKET-ENG MT ENG SI

Part Number: 85576429$52.76 MSRP: $83.02You Save: $30.26 (37%)Ships in 1-2 Business DaysChevrolet Colorado Engine Mount Assembly

Part Number: 84142207$84.65 MSRP: $140.10You Save: $55.45 (40%)Ships in 1-3 Business DaysChevrolet Colorado Bracket, Engine Mount Engine Side

Part Number: 23195925$61.08 MSRP: $96.10You Save: $35.02 (37%)

| Page 1 of 2 |Next >

1-20 of 22 Results

Chevrolet Colorado Engine Mount

The Engine Mount in Chevrolet Colorado vehicles fulfills two main duties by retaining both the engine and transaxle at their position and absorbing operational noise and vibrations. Safe vehicle operation requires this component as well as the delivery of comfortable driving experience. Standard Engine Mount use metal elements joined by rubber isolation yet newer hydraulic models reduce vibration more efficiently and electronic active mounts modify their stiffness according to engine rotational speed. The Chevrolet Colorado engineering team at different times incorporated three different kinds of Engine Mount which included rubber mounts as well as hydraulic mounts alongside active electronic mounts. Active Engine Mount stand at the advanced end of performance because they automatically adjust their operation according to what the driver experiences. The necessity of regular inspections emerges because Chevrolet Colorado Engine Mount deteriorate naturally and through heat exposure as well as fluid contact which might result in noise and vibration problems.

Each OEM Chevrolet Colorado Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Colorado Engine Mount Parts Questions & Experts Answers

- Q: Should engine mounts be replaced immediately if they are broken or deteriorated to prevent damage to driveline components in V8 engine on Chevrolet Colorado?A:Engine mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent damage to driveline components. During the check, the engine must be raised slightly to remove the weight from the mounts. Begin by raising the vehicle and securely supporting it on jackstands. Inspect the mounts for any cracks, hardened rubber, or separation from the metal plates, noting that the rubber may split down the center. Check for relative movement between the mount plates and the engine or frame using a large prybar; if movement is noted, check the tightness of the mount fasteners before condemning the mounts, as broken mounts typically allow the engine to move easily when pried or under load. To replace the mounts, disconnect the cable from the negative terminal of the battery, then raise the vehicle and support it securely on jackstands. For 4WD models, remove the interfering driveaxle. If working on the left mount, remove the left inner fender splash shield and the exhaust manifold heat shield on most models. Remove the engine mount-to-frame bracket bolts, noting that there are three bolts on each side securing the mounts to the frame bracket. Attach an engine hoist to the top of the engine for lifting; avoid using a jack under the Oil Pan to prevent damage to the oil pump pick-up. If a hoist is unavailable, a jack can be placed under the large casting lugs on each side of the engine block at the rear to support the engine's weight while replacing the mounts, though the starter motor must be removed to access the right side lug. Unbolt the mount from the engine block, then raise the engine enough to remove the mount from between the engine and the frame. Installation follows the reverse order of removal, using non-hardening thread-locking compound on the mount bolts and ensuring they are tightened to the specified torque.

Related Chevrolet Colorado Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount