My Garage

My Account

Cart

Genuine Chevrolet Corvette Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Engine Mounts found

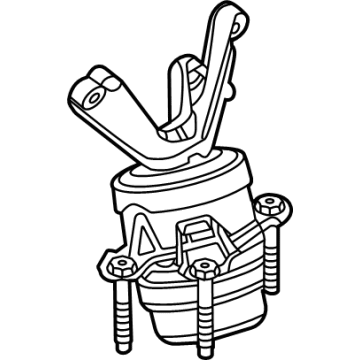

Chevrolet Corvette Engine Mount Assembly

Part Number: 15254700$79.80 MSRP: $136.45You Save: $56.65 (42%)Chevrolet Corvette Bracket, Engine Mount

Part Number: 23207231$39.30 MSRP: $67.20You Save: $27.90 (42%)Ships in 1-2 Business DaysChevrolet Corvette Mount Assembly, Engine

Part Number: 23187451$87.90 MSRP: $151.62You Save: $63.72 (43%)Ships in 1-2 Business DaysChevrolet Corvette Engine Mount Assembly

Part Number: 23187454$87.90 MSRP: $151.62You Save: $63.72 (43%)Ships in 1-2 Business DaysChevrolet Corvette Engine Mount Bracket

Part Number: 23207232$39.41 MSRP: $67.97You Save: $28.56 (43%)Ships in 1-2 Business DaysChevrolet Corvette Engine Mount Bracket

Part Number: 25796382$96.58 MSRP: $151.97You Save: $55.39 (37%)Ships in 1-3 Business DaysChevrolet Corvette Engine Mount Bracket

Part Number: 25796383$95.42 MSRP: $150.15You Save: $54.73 (37%)Ships in 1-3 Business DaysChevrolet Corvette MOUNT ASM,ENG

Part Number: 87819667$96.13 MSRP: $153.28You Save: $57.15 (38%)Ships in 1-3 Business DaysChevrolet Corvette Engine Mount Assembly

Part Number: 85038347$82.25 MSRP: $131.15You Save: $48.90 (38%)Ships in 1-2 Business DaysChevrolet Corvette Engine Mount Assembly

Part Number: 84675415$83.84 MSRP: $138.72You Save: $54.88 (40%)Ships in 1-3 Business DaysChevrolet Corvette Engine Mount Assembly

Part Number: 84675414$90.20 MSRP: $149.26You Save: $59.06 (40%)Ships in 1-3 Business DaysChevrolet Corvette MOUNT ASM,ENG

Part Number: 87819668$96.93 MSRP: $160.39You Save: $63.46 (40%)Ships in 1-3 Business DaysChevrolet Corvette Engine Mount Assembly

Part Number: 25966517$116.77 MSRP: $184.50You Save: $67.73 (37%)

| Page 1 of 2 |Next >

1-20 of 23 Results

Chevrolet Corvette Engine Mount

Each OEM Chevrolet Corvette Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Corvette Engine Mount Parts Questions & Experts Answers

- Q: Should engine mounts be replaced immediately if they are broken or deteriorated on Chevrolet Corvette?A:Engine mounts are one of the few components that are rarely troublesome, but when they are damaged or worn, they must be replaced right away to avoid damaging other components of the drivetrain. Checking the engine also requires raising it a bit off the mounts to drop the weight off the mounts. Lift the car and safely set it on jack stands; then putting a large piece of wood between the jack head and the engine Oil Pan, raise the engine only for a moment to take the load off the suspension and then slightly lowering the jack. Check the mounts for brittle rubber deformities, checking if the rubber has cracked or if the mounting has separated from the metal plates, the rubber can also have a central split. Use a large screwdriver or pry bar to palpate for relative motion between the mount plates and the location where the mount connects to the engine or frame; if rotation is detected, use an Allen wrench to tighten the available bolt or bolt and stud further before pronouncing the mounts as broken because this reproduces the symptom of a broken mount in which the engine can be moved around with your hand when the mounts are pried or the vehicle is loaded. In order to remove the mounts bring the vehicle up on jackstands, remove the under-vehicle splash shield if applicable, detach the cable from the negative terminal of the battery. Place the engine on the floor with the aid of the engine support fixture; unbolt the front subframe accompanied by the engine mount to subframe nut and then the engine mount to engine bracket nut to remove the mount from the bracket. Removal is the reverse of installation and requires removal of the mount bolts with non-hardening thread-locking compound applied and tightened to the prescribe torque.

Related Chevrolet Corvette Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount 1999 Engine Mount 1998 Engine Mount 1997 Engine Mount 1996 Engine Mount 1995 Engine Mount 1994 Engine Mount 1993 Engine Mount 1992 Engine Mount 1991 Engine Mount 1990 Engine Mount 1989 Engine Mount 1988 Engine Mount 1987 Engine Mount 1986 Engine Mount 1985 Engine Mount 1984 Engine Mount