My Garage

My Account

Cart

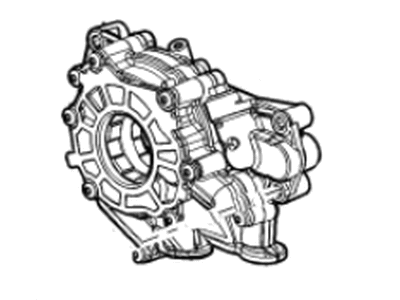

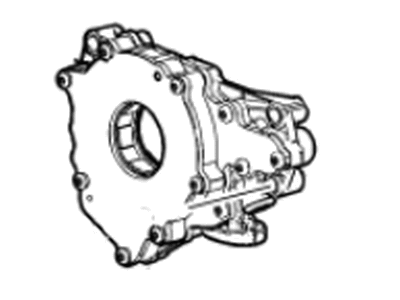

Genuine Chevrolet Corvette Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Oil Pumps found

Chevrolet Corvette Oil Pump Assembly

Part Number: 12710303$72.66 MSRP: $175.99You Save: $103.33 (59%)Ships in 1-2 Business DaysChevrolet Corvette Pump,Oil

Part Number: 93442037$160.92 MSRP: $275.17You Save: $114.25 (42%)Ships in 1-2 Business DaysChevrolet Corvette Oil Pump Assembly

Part Number: 12686435$424.84 MSRP: $726.46You Save: $301.62 (42%)Ships in 1-3 Business DaysChevrolet Corvette Oil Pump Assembly

Part Number: 12686434$169.54 MSRP: $280.60You Save: $111.06 (40%)Ships in 1-2 Business DaysChevrolet Corvette Pump,Oil

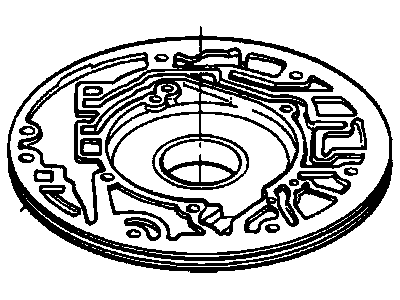

Part Number: 93427692$121.87 MSRP: $201.71You Save: $79.84 (40%)Ships in 1-3 Business DaysChevrolet Corvette BODY,A/TRNS FLUID PUMP

Part Number: 24299367$272.44 MSRP: $434.52You Save: $162.08 (38%)Ships in 1-3 Business DaysChevrolet Corvette Oil Pump Assembly

Part Number: 12695661$107.54 MSRP: $171.47You Save: $63.93 (38%)Ships in 1-3 Business DaysChevrolet Corvette PUMP KIT-OIL

Part Number: 12728436$914.35 MSRP: $1512.98You Save: $598.63 (40%)Ships in 1-3 Business DaysChevrolet Corvette Oil Pump Assembly

Part Number: 12707324$317.81 MSRP: $525.88You Save: $208.07 (40%)Ships in 1-3 Business DaysChevrolet Corvette BODY-A/TRNS FLUID PUMP

Part Number: 24048650$272.44 MSRP: $434.52You Save: $162.08 (38%)Ships in 1-3 Business DaysChevrolet Corvette Oil Pump Assembly

Part Number: 12623097$398.72 MSRP: $630.17You Save: $231.45 (37%)Chevrolet Corvette Oil Pump Assembly

Part Number: 12578147$394.92 MSRP: $624.17You Save: $229.25 (37%)

Chevrolet Corvette Oil Pump

In Chevrolet Corvette automobiles, the Oil Pump is very vital since it pumps oil under pressure to enable the dilemma of the internal combustion engine. This circulation ensures that such delicate parts such as bearings, pistons, and the camshaft are lubricated and cooled, and also acts as a hydraulic fluid for miniature actuators. Chevrolet Corvette has employed several styles of Oil Pumps, gear, trochoid and vaned pumps have been used, but due to mechanical pump reliabilities that can be either crankshaft or camshaft driven fashion was the norm. The oiling system in the Chevrolet Corvette pumps oil from the sump then filters then circulates this oil all round the engine, this is circulate by a pressure fundamental to the performance of the car. This is particularly so because high-performance models may feature state-of-the-art dry Sumps with more than one Oil Pumps to meet the heightened demands of lubrication at optimum revolutions per minute (RPMs). Some of the preventive maintenance recommended by the specialists in Chevrolet Corvette engines are changing the oil and filter as well as removing any accumulation that hampers the proper functioning of the system.

Each OEM Chevrolet Corvette Oil Pump we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Corvette Oil Pump Parts Questions & Experts Answers

- Q: How to remove and install the oil pump assembly on Chevrolet Corvette?A:An example of such design is a combination of two oil pump housings and two gear sets on the engines of 6.2L (LS3 with RPO Z52 dry sump oiling system), 6.2L (LS9) and 7.0L (LS7) whereas the pressure relief valve is shared. The front gear set adds oil up to the external oil tank and hence is known as the secondary pump while the rear gear set pumps oil directly to the engine hence the primary pump. Start with the removal of the timing chain cover as well as the Oil Pan as well. Subsequently, unscrew the oil pump pick-up tube mounting nut and the bolt, and as a result the pick-up tube and the screen which will be lowered off the vehicle; in addition, unbolt the other Crankshaft oil deflector bolts together with the deflector. After that, remove the oil pump retaining bolts and slide the pump over the end of the crankshaft. During inspection the oil pump cover is taken off and the rotors pulled out of the pump body, then clean the individual parts with solvent and examine the parts closely, including the bolt holes and splined surfaces of the crankshaft sprocket and observe for visible signs of damage. Any component of this assembly which may have been scored, scratched or worn, will require replacement of the complete oil pump assembly as there were no serviceable subassemblies available at the time of updating this publication. For installation, one must first start running in the pump by pouring fresh engine oil into the pick-up tube hole and while manually operating the pump. Place the oil pump over the extreme end of the crankshaft such that the teeth in the crankshaft sprocket engage on the oil pump drive gear and that of the pump rests on the block. Bolt the oil pump mounting back then tighten to the recommended torque. A new O-ring should be fitted to the pick-up tube of the oil pump, screw this to the oil pump and to the engine block main studs tighten the pick-up tube to oil pump bolts, sufficiently so that no air can get in to the oiling system. The oil pan is then secured back followed by all the other components such as the wheels as installation is done in reverse order of removal in Addition the oil is added before turning the engine on and also the coolant to check for oil and coolant leakage besides checking the oil pressure.

Related Chevrolet Corvette Parts

Browse by Year

2024 Oil Pump 2023 Oil Pump 2022 Oil Pump 2021 Oil Pump 2020 Oil Pump 2019 Oil Pump 2018 Oil Pump 2017 Oil Pump 2016 Oil Pump 2015 Oil Pump 2014 Oil Pump 2013 Oil Pump 2012 Oil Pump 2011 Oil Pump 2010 Oil Pump 2009 Oil Pump 2008 Oil Pump 2007 Oil Pump 2006 Oil Pump 2005 Oil Pump 2004 Oil Pump 2003 Oil Pump 2002 Oil Pump 2001 Oil Pump 2000 Oil Pump 1999 Oil Pump 1998 Oil Pump 1997 Oil Pump 1996 Oil Pump 1995 Oil Pump 1994 Oil Pump 1993 Oil Pump 1992 Oil Pump 1991 Oil Pump 1990 Oil Pump 1989 Oil Pump 1988 Oil Pump 1987 Oil Pump 1986 Oil Pump 1985 Oil Pump 1984 Oil Pump