My Garage

My Account

Cart

Genuine Chevrolet Cruze Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Headlights found

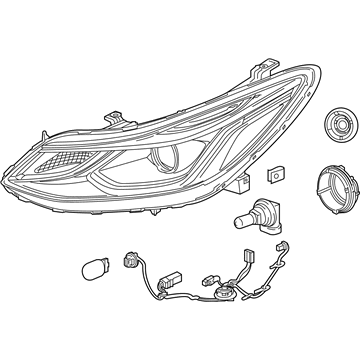

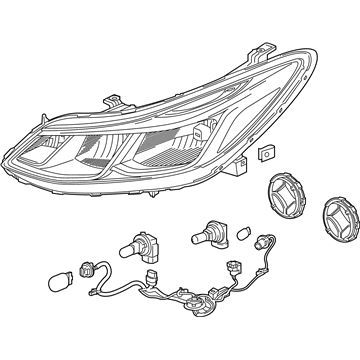

Chevrolet Cruze Headlamp Assembly With Parking & Turn Signal Lamp

Part Number: 95291964$297.86 MSRP: $451.39You Save: $153.53 (35%)Ships in 1-3 Business DaysChevrolet Cruze Headlamp Assembly, (W/ Parking & Turn Signal Lamp)

Part Number: 95291963$244.01 MSRP: $369.79You Save: $125.78 (35%)Ships in 1-3 Business DaysChevrolet Cruze Front Headlight Assembly

Part Number: 42680785$850.19 MSRP: $1278.64You Save: $428.45 (34%)Ships in 1-3 Business DaysChevrolet Cruze Front Headlight Assembly

Part Number: 42680786$818.72 MSRP: $1231.16You Save: $412.44 (34%)Ships in 1-3 Business DaysChevrolet Cruze Front Headlight Assembly

Part Number: 42680783$382.66 MSRP: $541.47You Save: $158.81 (30%)Ships in 1-2 Business DaysChevrolet Cruze Front Headlight Assembly

Part Number: 42680784$481.19 MSRP: $721.96You Save: $240.77 (34%)Ships in 1-3 Business DaysChevrolet Cruze Headlamp Assembly, (W/ Parking & Turn Signal Lamp)

Part Number: 95900042$87.68 MSRP: $126.01You Save: $38.33 (31%)Ships in 1-2 Business DaysChevrolet Cruze Headlamp Assembly With Parking & Turn Signal Lamp

Part Number: 95900041$111.22 MSRP: $167.03You Save: $55.81 (34%)Ships in 1-2 Business Days

Chevrolet Cruze Headlight

The Headlight of Chevrolet Cruze vehicles is another important feature that is primarily used to light up the road as well as seeing through the night while making sure that those on the other end of the road can easily see the approaching car. Chevrolet Cruze car headlights have changed with the time COmposite designs have also upgraded with better styling and improving aerodynamics. Different kinds of headlights have been used such as halogen, LED, and xenon kind of headlights which holds different benefits. Halogen is the most common bulb type because of its cost and although it lasts less than that of LED bulbs which are efficient and long-lasting. Xenon headlights are those that produces a bright white or bluish light which use the element xenon instead of failament. Current models of Chevrolet Cruze vehicle have incorporated modern features such as projector beams as part of its headlight system which enables a sharper light beam thereby improving the vehicle's safety and experience.

Each OEM Chevrolet Cruze Headlight we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Cruze Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to avoid blinding oncoming drivers and ensure safety on Chevrolet Cruze?A:The headlights should also therefore be aligned properly since they could blind other motorists on the road and cause some severe accidents or hinder one's vision. The aim should be checked at least every 12 months check, and every time a new headlamp is fitted, or any front end body repairs are carried out. There are no horizontal adjustment screws but the vertical adjustment screws are on the top of the headlight housing. A very basic setting up can be done by laying on masking tape on a blank wall and a level floor. First, stand a strip of masking tape along the vehicle's centerline and also along the centerlines of both headlights and then place another strip of masking tape horizontally across the vehicles' height. The specific conditions which the vehicle should meet including it had to be parked 25 feet away from the wall, level ground, half-full tank of gas, and no heavy load. Low beam adjustment can be controlled with respect to its high-intensity zone and it should be aligned two inches below the horizontal line with the help of the adjusting screw. In the case of low and high beams, it may not be possible to get the perfect aiming for both thus, it is recommendable to go for the aiming of the low beams as they are safer to use. In the car with the high beams activated the high-intensity zone should be directly below the line drawn horizontally. It should be wise to seek the services of the professional workshop, or service station to make the necessary adjustments to the headlights as soon as possible.