My Garage

My Account

Cart

Genuine Chevrolet Equinox Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Camshafts found

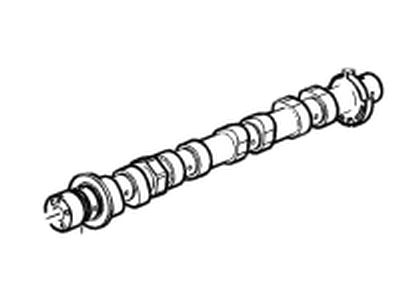

Chevrolet Equinox Exhaust Camshaft Assembly

Part Number: 12675774$94.62 MSRP: $150.93You Save: $56.31 (38%)Ships in 1-3 Business DaysChevrolet Equinox Exhaust Camshaft Assembly

Part Number: 12604896$97.65 MSRP: $168.48You Save: $70.83 (43%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft,Intake

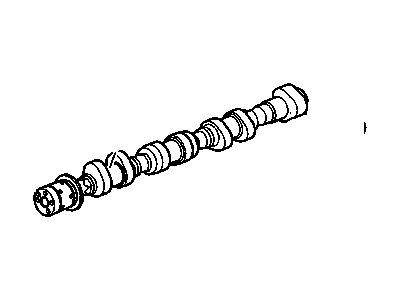

Part Number: 12638172$74.98 MSRP: $124.09You Save: $49.11 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft Assembly

Part Number: 12596567$231.04 MSRP: $324.27You Save: $93.23 (29%)Ships in 1-2 Business DaysChevrolet Equinox CAMSHAFT ASM,INT

Part Number: 19431713$264.75 MSRP: $422.26You Save: $157.51 (38%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft, Exhaust

Part Number: 12632270$49.62 MSRP: $120.12You Save: $70.50 (59%)Ships in 1-3 Business DaysChevrolet Equinox CAMSHAFT ASM,INT

Part Number: 19420032$245.91 MSRP: $406.90You Save: $160.99 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft Assembly, Exh (Lh)

Part Number: 12638399$89.38 MSRP: $147.98You Save: $58.60 (40%)Ships in 1-2 Business DaysChevrolet Equinox Camshaft Assembly, Intake

Part Number: 12626896$183.10 MSRP: $303.05You Save: $119.95 (40%)Ships in 1-2 Business DaysChevrolet Equinox Camshaft Assembly, Exh

Part Number: 12703359$444.49 MSRP: $735.67You Save: $291.18 (40%)Chevrolet Equinox Camshaft Assembly, Intake

Part Number: 12675781$73.37 MSRP: $121.42You Save: $48.05 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft, Intake (Machining)

Part Number: 55501297$89.39 MSRP: $142.53You Save: $53.14 (38%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft,Intake

Part Number: 12632272$78.94 MSRP: $125.85You Save: $46.91 (38%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft Assembly, Int

Part Number: 55511463$304.96 MSRP: $504.53You Save: $199.57 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft, Exhaust (Machining)

Part Number: 55501298$96.05 MSRP: $158.92You Save: $62.87 (40%)Ships in 1-3 Business DaysChevrolet Equinox CAMSHAFT ASM,EXH

Part Number: 19433783$189.59 MSRP: $309.00You Save: $119.41 (39%)Ships in 1-2 Business DaysChevrolet Equinox CAMSHAFT ASM-INT

Part Number: 12709697$63.45 MSRP: $104.99You Save: $41.54 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft Assembly, Exh

Part Number: 55513165$357.45 MSRP: $591.49You Save: $234.04 (40%)Ships in 1-3 Business DaysChevrolet Equinox Camshaft Assembly, Intake

Part Number: 12625986$28.77 MSRP: $45.26You Save: $16.49 (37%)

| Page 1 of 2 |Next >

1-20 of 28 Results

Chevrolet Equinox Camshaft

The camshaft in Chevrolet Equinox is involved in controlling the operations of the intake and exhaust valves thus allowing the flow of the air/fuel mixture and the expulsion of the exhaust gases. Usually made of iron or steel, Chevrolet Equinox camshaft relies on the following systems, OHV, SOHC, and DOHC which all affects the car performance in its own way. Lift, duration, and lobe separation angle are among the camshaft parameters that define the improvement of power output and alteration of idle quality. Performance camshafts improve the efficiency of air flow and power particularly at high engine speed while products enable specific alteration to specifications for performance enhancements. In general, the Chevrolet Equinox camshaft plays the critical role of coordinating the activity of the valves with piston action and greatly affects the car's efficiency and performance level.

Each OEM Chevrolet Equinox Camshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Equinox Camshaft Parts Questions & Experts Answers

- Q: How to Remove and Install the Camshafts in 3.0L and 3.6L V6 engine on Chevrolet Equinox?A:The camshaft bearing caps are numbered and lettered and are fitted with a raised arrow; the number refers to the bearing journal position from the front of the engine, the letter to the camshaft and the arrowhead is at the front. For this procedure, special timing chain holding tools EN 48383-2nd EN 48383-3rd are required; otherwise, the timing chain cover has to be detached in order to keep the chains connected to their lower sprockets. First of all, the negative battery cable should be disconnected, the valve cover(s) should be taken off, and depending on which camshafts are being removed the high-pressure fuel pump, for 3.0L, and the lower intake manifold, for 3.6L. Next to do, remove the Camshaft position sensors and the camshaft position actuator solenoid valves. Turn the engine over until the camshaft flats are parallel with the ground, measure the amount of In/Out and be very careful not to damage the camshaft. Lose the camshaft position actuator bolts, position the special tool to hold the timing chain and sprockets, then remove the actuator bolts. After the assembly place all the bearing caps in specifically marked box, unravel the camshaft bearing cap bolts in the reverse procedure that was used to tighten them, to do a check on the camshafts for wear or damages make use of the micrometer. Scrub the camshaft, check the bearing journals for any wear, measure the wear of the camshaft lobes and look for any signs of damage. Check the camshaft bearings and measure the bearing oil clearance; if clearance exceeds the standard it is usually advisable to replace the bearings and this is best done by a professional. For installation; before fitting the camshafts to the engine, the camshaft bearing journals and cam lobes needs to be lubricated, the correct position of the camshafts need to be ensured, the bearing caps need to be smeared with a layer of engine oil, and then the bearing caps have to be fitted to their correct position in the newly fitted camshafts. Loosen the bearing cap bolts and then assemble the cap back on the shaft and torque each of the bolt to required specifications. After ensuring the efficient working of the timing chain holding tool, start the engine and to finish the job reverse the whole process of removal. Before starting of the engine, it is required to replace the oil filter and to change the oil also.