My Garage

My Account

Cart

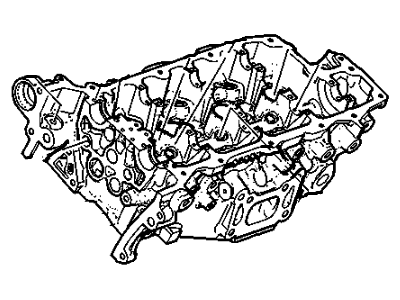

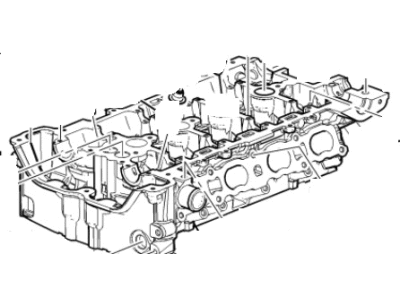

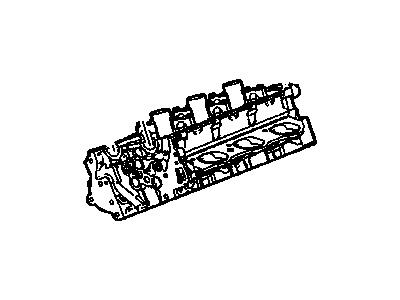

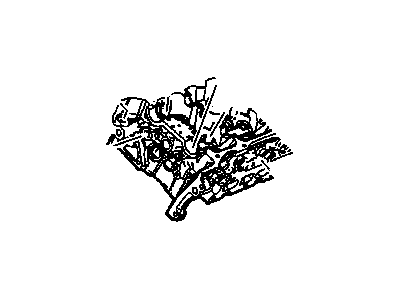

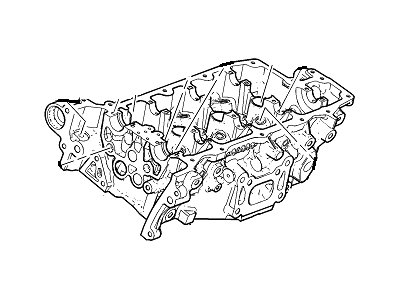

Genuine Chevrolet Equinox Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Cylinder Heads found

Chevrolet Equinox Cylinder Head Assembly With Valve

Part Number: 12679101$718.11 MSRP: $1185.92You Save: $467.81 (40%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head Assembly (Machining)

Part Number: 12608280$702.44 MSRP: $1428.81You Save: $726.37 (51%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head Assembly With Valve

Part Number: 55504792$596.76 MSRP: $987.68You Save: $390.92 (40%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head Assembly With Valve

Part Number: 12668716$408.87 MSRP: $676.72You Save: $267.85 (40%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head (W/Vlvs)

Part Number: 12641095$891.09 MSRP: $1418.68You Save: $527.59 (38%)Ships in 1-3 Business DaysChevrolet Equinox Head Assembly, Cyl (W/ Vlv)

Part Number: 12690428$1076.04 MSRP: $1713.67You Save: $637.63 (38%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head Assembly (W/ Valve) (Rh)

Part Number: 12686767$856.78 MSRP: $1366.17You Save: $509.39 (38%)Ships in 1-3 Business DaysChevrolet Equinox Engine Cylinder Head (W/Vlvs)

Part Number: 12635548$299.00 MSRP: $474.37You Save: $175.37 (37%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head Assembly With Valve

Part Number: 12692322$1093.89 MSRP: $1810.08You Save: $716.19 (40%)Ships in 1-3 Business DaysChevrolet Equinox Engine Cylinder Head (Machining)

Part Number: 12611606$878.50 MSRP: $1401.13You Save: $522.63 (38%)Ships in 1-3 Business DaysChevrolet Equinox Cylinder Head (W/Vlvs)

Part Number: 12641093$620.59 MSRP: $1024.53You Save: $403.94 (40%)Ships in 1-3 Business DaysChevrolet Equinox HEAD ASM-CYL (W/ VLV)

Part Number: 12708953$563.37 MSRP: $898.51You Save: $335.14 (38%)Ships in 1-3 Business DaysChevrolet Equinox Engine Cylinder Head (W/Vlvs)

Part Number: 12641100$878.50 MSRP: $1401.13You Save: $522.63 (38%)Chevrolet Equinox Cylinder Head Kit

Part Number: 12641701$444.88 MSRP: $703.82You Save: $258.94 (37%)Chevrolet Equinox Cylinder Head Assembly

Part Number: 12586926$353.92 MSRP: $556.89You Save: $202.97 (37%)Chevrolet Equinox Cylinder Head Assembly With Valve

Part Number: 55501671$490.30 MSRP: $778.44You Save: $288.14 (38%)Chevrolet Equinox HEAD ASM,CYL (REMAN)

Part Number: 19419467$1090.09 MSRP: $1728.22You Save: $638.13 (37%)

Chevrolet Equinox Cylinder Head

The Chevrolet Equinox vehicle uses a Cylinder Head as an important engine aspect that enables air and fuel entry into the motor while managing exhaust gas releases. The Cylinder Head contains valves and spark plugs and it fulfills the top chamber role of the combustion process. The prohibition of aluminum Cylinder Heads has become the standard for Equinox models because they reduce vehicle weight while improving power output compared to overall weight and better heat management capabilities lead to increased compression rates. The Chevrolet Cylinder Head suffers from common defects through which performance degradation happens because of compression problems or leakages that result from warpage or cracking conditions. A sealing method called torque-to-yield (TTY) head bolts exists to provide greater bolt clamping compared to regular bolts. The Chevrolet Equinox Cylinder Head remains essential for achieving efficient engine operation because end product designers continue to enhance it for better airflow management and less performance limitations.

Each OEM Chevrolet Equinox Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Equinox Cylinder Head Parts Questions & Experts Answers

- Q: What precautions should be taken when removing the engine head to prevent warpage and ensure proper installation in 2.4L four Cylinder Head engine on Chevrolet Equinox?A:The head should not be removed until the engine is cold since this can cause the head to warp and new head bolts should be acquired beforehand. Let begin by reducing the pressure of fuel system and then removing the connection of the cable from the terminal of battery negative. It is preferable to do it when the engine is cold but should you wish to do it while running, wait for it to cool and drain the cooling system. This is done by uninstalling the coolant recovery tank and upper radiator hose, the drivebelt and the drivebelt tensioner. Then take out the exhaust manifold, and intake manifold and finally the valve cover before taking out the Timing Chain. You can run the cylinder head with the timing chain cover and timer chain still in place with the aid of some tools but it is advisable to take it off. Identify and remove connect the electrical connectors that may hinder removal procedures by applying a tag on the correct position of each connector to assist in proper reconnection. To do this, one has to take out and then discard the cylinder head bolts which have to be loosened at a ¼ turn starting intervals. Where the gasket seal separates the head and block, pry at corners of the head-to-block mating surface do not pry in gasket sealing zone. Raise the cylinder head off the engine: if there is some sort of resistance felt, the application of a wood block and hammer should be used and the position of the cylinder head should be on wood blocks so as not to develop some sort of crack. Also, it is necessary to unscrew the old cylinder head gasket, paying attention to the method of further assembly-its top side should be installed up. Use gasket scraper before installing the cylinder head block to make sure each surface of both cylinder head and block to be perfectly clean and then apply brake system cleaner. Open spaces of the engine should be covered with shop rags to prevent particles from falling, and the way should then be vacuum cleaned to clear the cylinders. Also look for cracks where the engine block and cylinder head join, the holes should also be cleaned with a nylon bristle brush. Put the new gasket on the dowels in the block, place the cylinder head on the engine block in such manner that it does not shift the gasket, and fit new cylinder head bolts and turn them to the right torque, in the correct order. The main Cylinder head bolts tightening is done in the first and second steps and the four small bolts in front are tightened in the third step. Place a tick sign on each of the main cylinder head bolts to identify those tightened a further by an angle of fifteen five degrees. The head bolt tightening procedure comes in with a torque angle sequence and a torque angle gauge can be used in the process. Later put the timing chain, exhaust manifold and Intake Manifold respectively once you finished put the components in the reverse order that you removed them.. Connect the battery, replace the oil and the oil filter, add more coolant to the system, turn on the engine and observe it closely for any oil and water flicker.

Related Chevrolet Equinox Parts

Browse by Year

2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head