My Garage

My Account

Cart

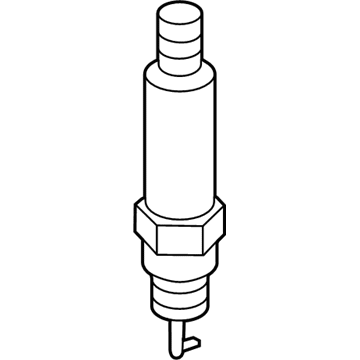

Genuine Chevrolet Impala Spark Plug

Ignition Spark Plug- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Spark Plugs found

Chevrolet Impala Spark Plug Assembly, Gasoline Engine Ignition

Part Number: 12681660$9.05 MSRP: $16.46You Save: $7.41 (46%)Ships in 1-3 Business DaysChevrolet Impala SPARK PLUG ASM,GAS ENG IGN

Part Number: 19417055$9.36 MSRP: $17.02You Save: $7.66 (46%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Assembly, Gas Eng Ign

Part Number: 12680074$9.38 MSRP: $17.06You Save: $7.68 (46%)Chevrolet Impala Spark Plug Assembly, Gas Eng Ign

Part Number: 12681658$9.05 MSRP: $16.46You Save: $7.41 (46%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Assembly, Gas Eng Ign

Part Number: 12681664$9.05 MSRP: $16.46You Save: $7.41 (46%)Ships in 1-2 Business DaysChevrolet Impala Spark Plug

Part Number: 12681662$11.15 MSRP: $20.28You Save: $9.13 (46%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Asm

Part Number: 19301808$8.01 MSRP: $14.56You Save: $6.55 (45%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Assembly

Part Number: 19301810$7.57 MSRP: $13.76You Save: $6.19 (45%)Ships in 1-2 Business DaysChevrolet Impala Spark Plug Assembly

Part Number: 19300875$7.57 MSRP: $13.76You Save: $6.19 (45%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Asm

Part Number: 19301813$7.93 MSRP: $14.42You Save: $6.49 (46%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Asm,Gasoline Engine Ignition

Part Number: 19354430$2.40 MSRP: $4.36You Save: $1.96 (45%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Asm,Gasoline Engine Ignition

Part Number: 19354415$2.30 MSRP: $4.18You Save: $1.88 (45%)Ships in 1-3 Business DaysChevrolet Impala Spark Plug Asm

Part Number: 92457960$9.18 MSRP: $16.46You Save: $7.28 (45%)Ships in 1-3 Business Days

Chevrolet Impala Spark Plug

Chevrolet Impala automobiles have Spark Plug that has the function of igniting the combustion process through creating a spark that ignites the mixture comprising of fuel and air in the chamber of combustion for the vehicle's Impala model. It comprise of shell made of metal, electrode and ceramic insulator and the efficiency of this component depends on high voltage. For quite some time now, different styles of the Spark Plug have been used in the Chevrolet Impala models, which include the types with multiple ground electrodes and the surface-discharge styles, which improve ignition, effectiveness and durability. Here again the kind of gap and heat range needed for the premier operation and to avoid damage to the engines must be maintained. It is also possible to get some clues about the engine state by examining The Spark Plug condition.

Each OEM Chevrolet Impala Spark Plug we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Impala Spark Plug Parts Questions & Experts Answers

- Q: What are the steps and tools necessary for replacing spark plugs on Chevrolet Impala?A:They are mounted on the cylinder head(s) and the equipment required to change them are a spark plug socket compatible with a ratchet, various extensions, a gap wire used to check the gap of the new spark plugs and a torque meter used in tightening. It is also good to have new plugs and adjust their gap before fitting them; it is also recommended that they need to be changed one at a time so as to ensure that the correct type is provided for the specific engine. It is advisable not to pull out the removed plugs until the engines have cooled when already on the garage floor make sure that the new plugs do not have any defects and that the gap is right. Using the proper thickness-gauge one checks the gap and if the gap is to be adjusted, then one should bend the side electrode properly because bending it roughly may cause some harm to the porcelain insulator. For V6 models, air intake duct could be detached and on V8 models, rear bank ignition coil mounting bracket could be unbolted to provide good access to the rear spark plugs. When disconnected the spark plug wire, pull only the boot, if necessary twirl compressed air to blow into the spark plug hole. To take off the spark plug, use the socket and turn it anti-clockwise, then examine the old plug relative to the new spark plugs for the condition of the engine when running. If one is changed with bare hands, screw in a new plug until the last turns are very tight, then tighten it to preset standards with the help of a torque wrench or a ratchet; a short rubber hose is useful to thread it home without risk of cross-threading. Before fitting the spark plug wire to the new plug turn it round and round in order to have a tight connection for all the spark plugs in place so as not to confuse the wires while replacing each of the plugs separately.

Related Chevrolet Impala Parts

Browse by Year

2020 Spark Plug 2019 Spark Plug 2018 Spark Plug 2017 Spark Plug 2016 Spark Plug 2015 Spark Plug 2014 Spark Plug 2013 Spark Plug 2012 Spark Plug 2011 Spark Plug 2010 Spark Plug 2009 Spark Plug 2008 Spark Plug 2007 Spark Plug 2006 Spark Plug 2005 Spark Plug 2004 Spark Plug 2003 Spark Plug 2002 Spark Plug 2001 Spark Plug 2000 Spark Plug 1995 Spark Plug 1994 Spark Plug 1985 Spark Plug 1984 Spark Plug 1983 Spark Plug 1982 Spark Plug