My Garage

My Account

Cart

Genuine Chevrolet Malibu Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

64 Brake Lines found

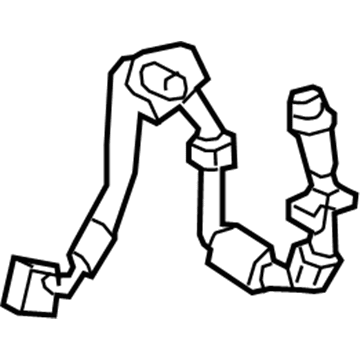

Chevrolet Malibu Pipe,Brake

Part Number: 88983905$68.37 MSRP: $134.44You Save: $66.07 (50%)Ships in 1-3 Business DaysChevrolet Malibu Hose Assembly, Front Brake

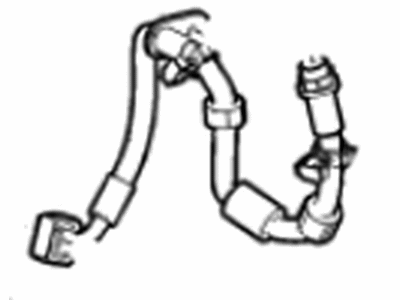

Part Number: 84025387$15.57 MSRP: $29.35You Save: $13.78 (47%)Chevrolet Malibu Front Brake Hose

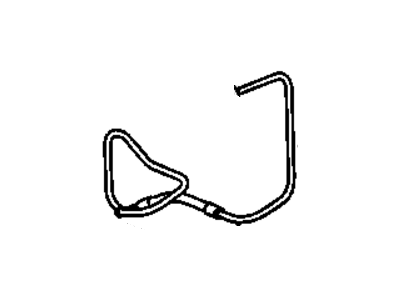

Part Number: 25874781$25.09 MSRP: $45.65You Save: $20.56 (46%)Ships in 1-2 Business DaysChevrolet Malibu Power Brake Booster Vacuum Pipe Assembly

Part Number: 23183114$51.70 MSRP: $101.64You Save: $49.94 (50%)Ships in 1-2 Business DaysChevrolet Malibu Rear Brake Hose Assembly

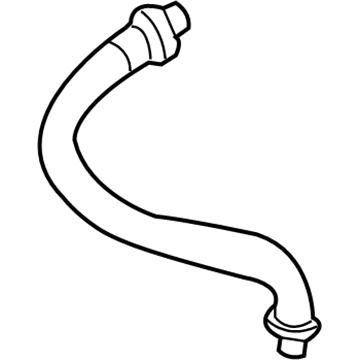

Part Number: 84025411$15.90 MSRP: $30.00You Save: $14.10 (47%)Ships in 1-2 Business DaysChevrolet Malibu Pipe Assembly, Brake Pressure Mod Valve

Part Number: 13227575$14.44 MSRP: $27.27You Save: $12.83 (48%)Ships in 1-2 Business DaysChevrolet Malibu Rear Brake Hose Assembly

Part Number: 84068589$7.07 MSRP: $13.35You Save: $6.28 (48%)Ships in 1-2 Business DaysChevrolet Malibu Pipe,Brake

Part Number: 93178453$26.87 MSRP: $48.86You Save: $21.99 (46%)Ships in 1-2 Business DaysChevrolet Malibu Hose Assembly, Front Brake

Part Number: 84289369$7.92 MSRP: $14.96You Save: $7.04 (48%)Ships in 1-2 Business DaysChevrolet Malibu Front Brake Hose Assembly

Part Number: 84552908$8.22 MSRP: $14.96You Save: $6.74 (46%)Ships in 1-2 Business DaysChevrolet Malibu Rear Brake Hose Assembly

Part Number: 84552905$9.67 MSRP: $17.57You Save: $7.90 (45%)Ships in 1-2 Business DaysChevrolet Malibu Hose Assembly, Rear Brake

Part Number: 84068588$7.81 MSRP: $14.74You Save: $6.93 (48%)Ships in 1-2 Business DaysChevrolet Malibu Front Brake Hose Assembly

Part Number: 84199638$9.26 MSRP: $17.48You Save: $8.22 (48%)Ships in 1-2 Business DaysChevrolet Malibu Hose Assembly, Rear Brk (Rh Proc)

Part Number: 84552902$8.27 MSRP: $15.04You Save: $6.77 (46%)Ships in 1-3 Business DaysChevrolet Malibu Rear Brake Hose Assembly

Part Number: 84552901$8.43 MSRP: $15.32You Save: $6.89 (45%)Ships in 1-3 Business DaysChevrolet Malibu Front Brake Hose Assembly

Part Number: 84199637$9.61 MSRP: $17.48You Save: $7.87 (46%)Ships in 1-2 Business DaysChevrolet Malibu Pipe Assembly, Brk Press Mod Vlv

Part Number: 84635260$39.57 MSRP: $74.66You Save: $35.09 (47%)Ships in 1-2 Business DaysChevrolet Malibu Pipe Assembly, Brake Master Cylinder Reservoir

Part Number: 25805870$39.87 MSRP: $63.45You Save: $23.58 (38%)Ships in 1-2 Business DaysChevrolet Malibu Pipe Assembly, Brake Pressure Mod Valve

Part Number: 13227576$15.28 MSRP: $27.39You Save: $12.11 (45%)

| Page 1 of 4 |Next >

1-20 of 64 Results

Chevrolet Malibu Brake Line

This page details the function of the Brake Line in relation to Chevrolet Malibu vehicles because it supplies brake fluid from the master cylinder to the brake caliper pistons and fuels the hydraulic brake system. Through this, the vehicle can decelerate or stop as desired also when the brake pedal is pressed. Through the years, Chevrolet Malibu has used different sorts of Brake Lines like the metal brake lines as well as the rubber brake hoses. Brake shoe involving metal brake lines can easily rust leading to fluid leaks as well as reducing the hydraulic pressure especially during winter seasons. However, there are disadvantages of using rubber brake hoses Some of them include physical damage, internal wear and tear as well as improper installation. For better performance, installing new Racing style of Braided stainless steel Brake Lines gives much better and firmer pedal feel than the normal rubber hoses during highway fast driving.

Each OEM Chevrolet Malibu Brake Line we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Brake Line Parts Questions & Experts Answers

- Q: How often should you inspect the flexible hoses connecting the steel brake lines to the brake assemblies on Chevrolet Malibu?A:Approximately once in every 6 months, with the vehicle off the ground and supported on jack stands, check the flexible hoses that connect the steel lines to the front and rear brake assemblies as these are vital components of the brake system, for cracks, chafing, leaks, and blisters etc. A well-done check needs a light and a mirror and if there is a damaged hose, it is more preferable to replace the hose with a new one. First off, free all the dirt that can be aired out from the hose ends then use the flare-nut wrench to free the tube nut in a way that the corners are not rounded off, and then free all bolts, clips or grommets that lock the hose. Remove the hose from the caliper and dispose off the sealing washers then connect the new brake hose by using new sealing washers and tightening the banjo fitting bolt to the right degree of torque. Installation is the reverse of removal, and tighten any slack out of the hose; also, make sure any suspension or steering components do not contact the hose while an assistant thumps the tire and turns the steering wheel lock to lock. When replacing brake lines, always use the right parts with no use of copper tubing, obtain steel brake lines from a dealer or auto parts store. There are available Ready made brake lines with flared tube ends but with fittings pre-installed and the tubing can be bent to the required shapes with the help of a tubing bender. It should also be pointed out that the new line should be well grounded in brackets and should be located a safe distance from moving or hot components. Before normal operation carry out gentle testing of brakes after installation, replenish the master cylinder, add fluid and bleed the system as required.

Related Chevrolet Malibu Parts

Browse by Year

2024 Brake Line 2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line