My Garage

My Account

Cart

Genuine Chevrolet Malibu Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Engine Mounts found

Chevrolet Malibu Mount Assembly, Engine

Part Number: 22708433$121.61 MSRP: $193.56You Save: $71.95 (38%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Bracket

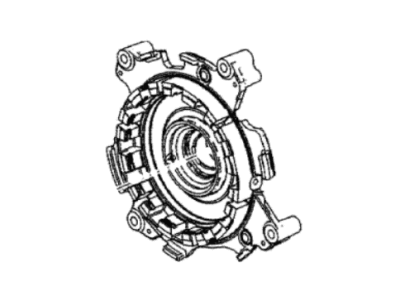

Part Number: 24504187$46.61 MSRP: $77.14You Save: $30.53 (40%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Assembly

Part Number: 84034329$82.80 MSRP: $141.58You Save: $58.78 (42%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Assembly

Part Number: 84034314$88.33 MSRP: $152.36You Save: $64.03 (43%)Ships in 1-2 Business DaysChevrolet Malibu Bracket, Engine Mount Snubber

Part Number: 15235774$4.05 MSRP: $6.38You Save: $2.33 (37%)Ships in 1-3 Business DaysChevrolet Malibu Bracket, Engine Mount Snubber

Part Number: 25791904$82.95 MSRP: $132.29You Save: $49.34 (38%)Ships in 1-3 Business DaysChevrolet Malibu Engine Mount Bracket

Part Number: 22937294$55.38 MSRP: $134.07You Save: $78.69 (59%)Ships in 1-3 Business DaysChevrolet Malibu Engine Mount Assembly

Part Number: 84125837$104.24 MSRP: $178.21You Save: $73.97 (42%)Chevrolet Malibu Engine Mount Bracket

Part Number: 13227754$26.71 MSRP: $42.61You Save: $15.90 (38%)Ships in 1-3 Business DaysChevrolet Malibu Support Asm,Drive Motor (Kit)

Part Number: 24281034$93.69 MSRP: $121.68You Save: $27.99 (23%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Assembly

Part Number: 23144105$103.14 MSRP: $177.91You Save: $74.77 (43%)Ships in 1-2 Business DaysChevrolet Malibu Mount Assembly, Engine

Part Number: 22744337$85.65 MSRP: $146.46You Save: $60.81 (42%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Assembly

Part Number: 25852869$84.92 MSRP: $145.21You Save: $60.29 (42%)Ships in 1-2 Business DaysChevrolet Malibu Engine Mount Bracket

Part Number: 23375491$72.66 MSRP: $114.34You Save: $41.68 (37%)Ships in 1-3 Business DaysChevrolet Malibu Engine Mount

Part Number: 25852870$79.30 MSRP: $135.60You Save: $56.30 (42%)Ships in 1-2 Business DaysChevrolet Malibu Reinforcement, Engine Mount Bracket

Part Number: 23423029$11.09 MSRP: $17.46You Save: $6.37 (37%)Ships in 1-3 Business DaysChevrolet Malibu Support Assembly, Drive Motor (2Nd Position)

Part Number: 24277039$90.06 MSRP: $149.06You Save: $59.00 (40%)Ships in 1-2 Business DaysChevrolet Malibu Brace, Eng Mt

Part Number: 84904002$8.50 MSRP: $13.36You Save: $4.86 (37%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Chevrolet Malibu Engine Mount

In Chevrolet Malibu vehicles the Engine Mount fulfills dual roles as it diminishes engine-operated noise and vibration and provides stable foundation for the engine at its chassis position. A strong and efficient Engine Mount achieves both driving comfort and safe operation of the vehicle. The basic Engine Mount configuration uses rubber insulated metal pieces for traditional mounts while hydraulic hydromounts represent modern solutions for improved vibration reduction. Active electronic mounts represent the top engineering solution because they alter their stiffness through engine speed adaptations for improved performance outcomes. Different Chevrolet Engine Mount systems have become standard features in Malibu vehicles since their introduction. As rubber mounts age through time they become spongy or separate from each other but hydraulic mounts can develop fluid leakage problems. Active mounts provide enhanced adaptation to driving conditions and need special diagnostic tools for assessment although they perform better than standard solutions. Regular checks play an essential role in upholding the integrity of Chevrolet Malibu Engine Mounts which results in superior possible vehicle performance levels.

Each OEM Chevrolet Malibu Engine Mount we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Engine Mount Parts Questions & Experts Answers

- Q: How should engine mounts be inspected and replaced to prevent damage to drive line components in four cylinder engine on Chevrolet Malibu?A:Engine mounts are usually trouble free, but if there are broken or worn out ones, they should be replaced to avoid damaging the drive line. To inspect the mounts, support the vehicle on jack stands and place a jack under the engine Oil Pan on top what is a block of wood. Lever it a little just enough to take some of the weight off the mounts, then check for cracks, turning to metal and separation of the rubber from the bushing. Insert a large screwdriver or pry bar between the mount and the engine or frame; look for any relative movement; if movement is noted, reduce the weight of the mount fasteners. Whenever the mount is removed, the negative cable of the battery has to be detached and depending on which mount is being removed some other parts like the air filter housing, battery tray etc. Lift the vehicle on jack stands once more, and then insert a piece of wood firmly between the head of the jack and the oil pan to take load off the engine/trans axle if the vehicle is to be left elevated for some time. Precautionary measures, especially should not more than one mount be disconnected at a given time unless the engine is to be removed. To achieve this perform the power train mounts, to balance the engine trans axle assembly make sure that the assembling has balanced weight and then tighten the mounting bolts. Apply floor jacks to support both the engine and trans axle then unbolt the required studs and nuts related to the mounts and their brackets then further space the separates by as much as a quarter inch. Position the front and rear trans axle mounts in their brackets, after that, fasten five bolts up to the specified torque. Last lift the floor jacks, place the vehicle using jack stands, move the engine and trans axle up and down, tighten the rear through-bolt, retract the under-vehicle splash shield and finally brought down the vehicle.

Related Chevrolet Malibu Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount 1999 Engine Mount 1998 Engine Mount 1997 Engine Mount