My Garage

My Account

Cart

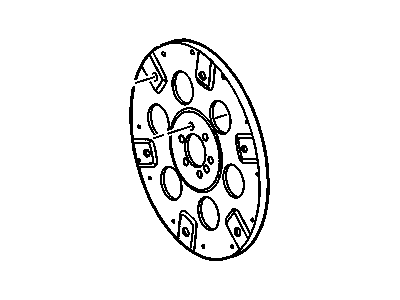

Genuine Chevrolet Metro Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Flywheels found

Chevrolet Metro Engine Crankshaft FLYWHEEL

Part Number: 91173838$96.14 MSRP: $178.38You Save: $82.24 (47%)Ships in 1-2 Business Days

Chevrolet Metro Flywheel

A Chevrolet Metro Flywheel plays three crucial roles to support the engine: first by storing rotational power to level engine torque then by activating starter engagement to spin the crankshaft lastly by serving as a slipping surface for the clutch component. As a crankshaft component the Flywheel achieves continuous power by reducing the engine's combustion pulse variations during rotation with the motor. The automotive industry relies on two different kinds of Flywheel which include solid Flywheel and dual mass Flywheel (DMFs). The damping unit on DMFs absorbs engine vibrations which improves performance mainly for diesel engines. Continuous relation between the clutch and the Flywheel results in wear which creates scoring and warpage that requires equipment replacement or complete resurfacing. The replacement process should be avoided for DMFs because damaged units need to be fully replaced instead of resurfaced. The continuous use of the replacement unit ring gear causes it to wear out requiring potential equipment replacement. The Chevrolet Metro engine and transmission system functions optimally because of the essential Chevrolet Metro replacement part component.

Each OEM Chevrolet Metro Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Metro Flywheel Parts Questions & Experts Answers

- Q: How to properly remove and reinstall the flywheel/driveplate on Chevrolet Metro?A:Raise the vehicle and support it securely on jackstands, then remove the transaxle. If it's leaking, now would be a very good time to replace the front pump seal/O-ring for automatic transaxle models. Remove the pressure plate and clutch disc for manual transaxle equipped models, and check or replace the clutch components and pilot bearing. For automatic transaxle models, mark the relationship between the driveplate and crankshaft to ensure correct alignment during reinstallation. Remove the bolts that secure the flywheel/driveplate to the crankshaft, immobilizing it by jamming a heavy screwdriver into the ring gear teeth if it turns. Carefully remove the flywheel/driveplate from the crankshaft, supporting it while removing the last bolt due to its weight. Clean the flywheel to remove grease and oil, inspecting the surface for cracks, rivet grooves, burned areas, and score marks, with light scoring removable using emery cloth. Check for cracked and broken ring gear teeth, laying the flywheel on a flat surface to check for warpage with a straightedge. Clean and inspect the mating surfaces of the flywheel/driveplate and the crankshaft, replacing the crankshaft oil seal if it is leaking before reinstalling the flywheel/driveplate. Position the flywheel/driveplate against the crankshaft, aligning the hole in the flywheel with the alignment dowel in the crankshaft for manual transaxle models, or aligning the marks made during removal for automatic transaxle models. Before installing the bolts, apply thread locking compound to the threads and tighten them to the specified torque while keeping the crankshaft from turning. The remainder of installation follows the reverse of the removal procedure.